Garment comprising protective element and manufacturing method thereof

A technology for protective elements and clothing, applied in the field of clothing, can solve the problems of poor air permeability of the full airbag package, inability to protect the arms and elbows, and inability to protect the human body, so as to increase the waterproof and antifouling performance, increase the antifouling performance, increase the The effect of insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

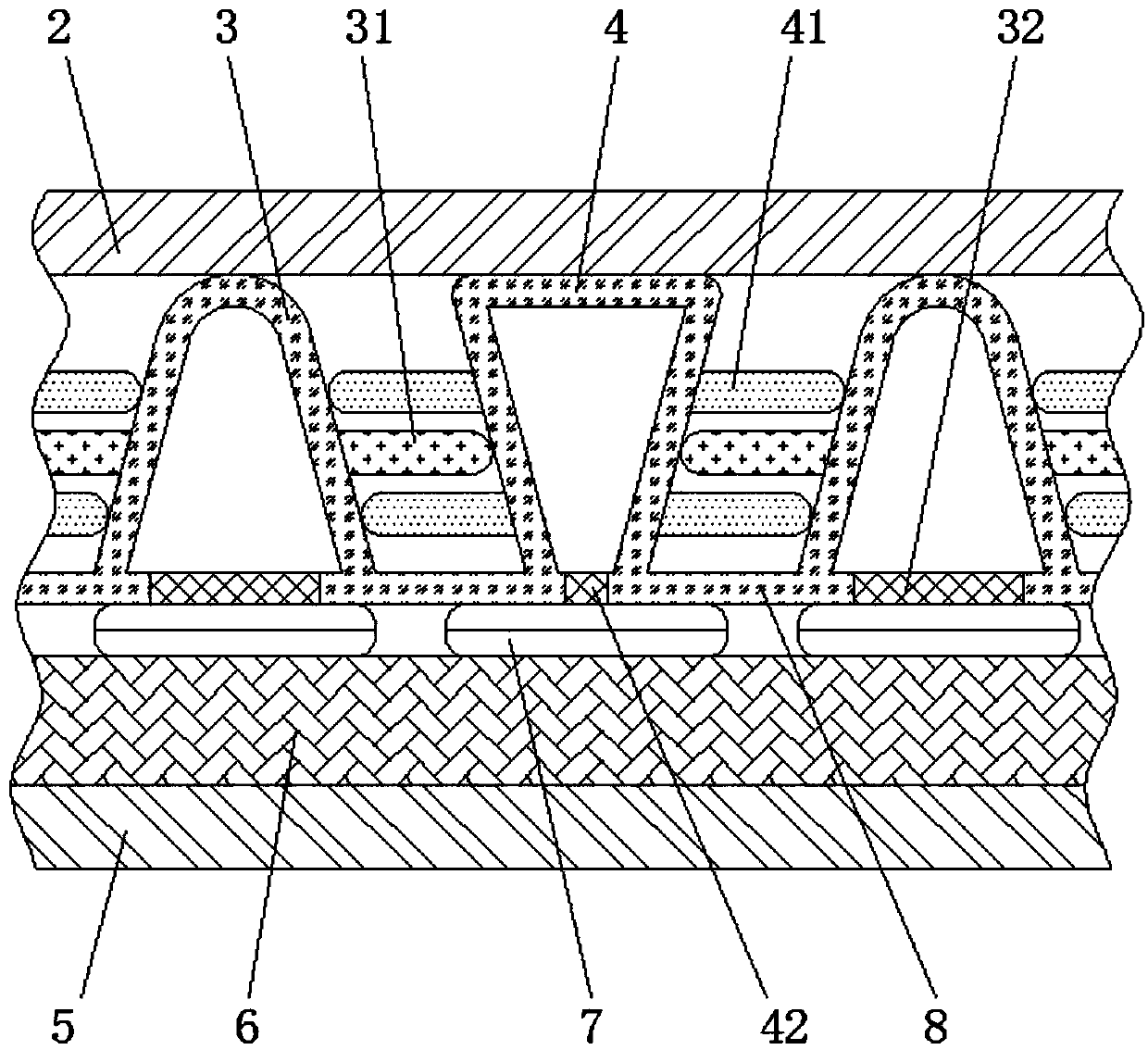

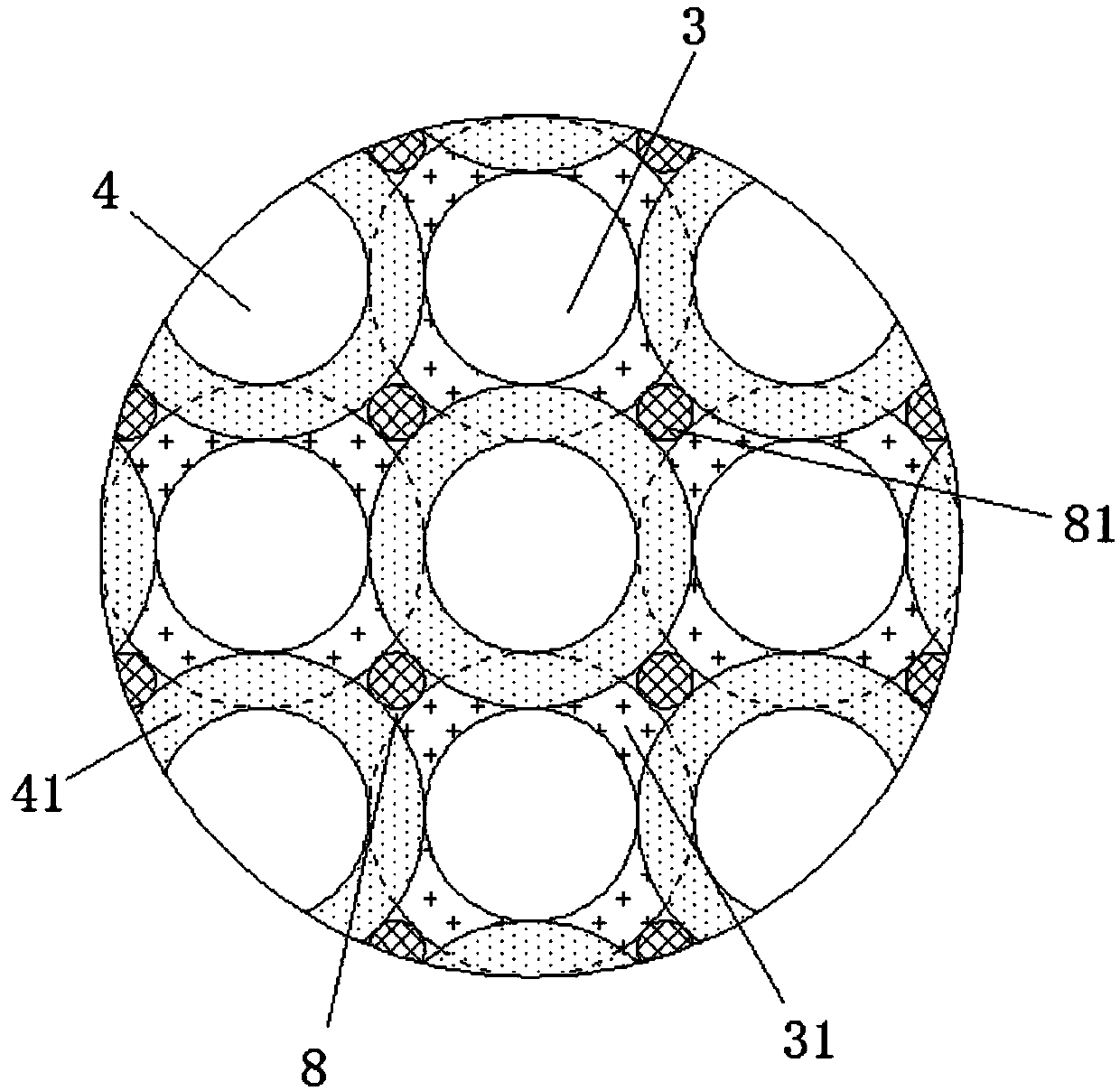

[0048] A method for manufacturing the above-mentioned protective element clothing, when manufacturing the protective element clothing, comprises the following steps:

[0049] a. Take one aramid fiber 21, the first stainless steel wire 22 and the spandex fiber 23, intertwine and twist them into strands, and use a braiding machine to twist and weave a plurality of strands of fibers to obtain the outer layer fabric 2;

[0050] b. Take one strand 51, 52 and 53, intertwine and twist them into strands, and twist and weave a plurality of strands of fibers through a braiding machine to obtain the inner layer fabric 5;

[0051] c. Pre-treating the outer layer fabric 2 and the inner layer fabric 5, followed by desizing, scouring, cleaning, drying and singeing, and then set aside;

[0052] d. Select the dye of the required color, dye, wash and dry the outer layer fabric 2 and the inner layer fabric 5 respectively, and set aside;

[0053] e. Select 100 parts of polyurethane resin, 20 par...

Embodiment 2

[0058] The difference between this example and Example 1 is that in step e, 150 parts of polyurethane resin, 30 parts of coupling agent, 40 parts of crosslinking agent, 20 parts of plasticizer, 20 parts of penetrant and 500 parts of water are selected for mixing and stirring , to prepare a waterproof and antifouling coating, and dip the outer layer of cloth 2 and the inner layer of cloth 5 into the waterproof and antifouling coating for padding, the dipping time of the outer layer of cloth 2 and the inner layer of cloth 5 is 45 minutes, effectively making the waterproof and antifouling coating Immerse in the fibers of the outer layer fabric 2 and the inner layer fabric 5, thereby increasing the waterproof and anti-fouling properties of the outer layer fabric 2 and the inner layer fabric 5, then dry the outer layer fabric 2 and the inner layer fabric 5 after padding, and set aside;

[0059] Others are the same as embodiment 1.

Embodiment 3

[0061] The difference between this example and Example 1 is that in step e, 200 parts of polyurethane resin, 40 parts of coupling agent, 50 parts of crosslinking agent, 30 parts of plasticizer, 30 parts of penetrant and 600 parts of water are selected for mixing and stirring , to prepare a waterproof and antifouling coating, and dip the outer layer of cloth 2 and the inner layer of cloth 5 into the waterproof and antifouling coating for padding. The dipping time of the outer layer of cloth 2 and the inner layer of cloth 5 is 60 minutes, effectively making the waterproof and antifouling coating Immerse in the fibers of the outer layer fabric 2 and the inner layer fabric 5, thereby increasing the waterproof and anti-fouling properties of the outer layer fabric 2 and the inner layer fabric 5, then dry the outer layer fabric 2 and the inner layer fabric 5 after padding, and set aside;

[0062] Others are the same as embodiment 1.

[0063] Working principle: When the user wears it ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com