Rapid leveling ultra-thin grid adhesive tape and preparation method thereof

A grid, ultra-thin technology, used in adhesives, pressure-sensitive films/sheets, film/sheet release liners, etc. Combines fast leveling, excellent temperature resistance, and high fit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

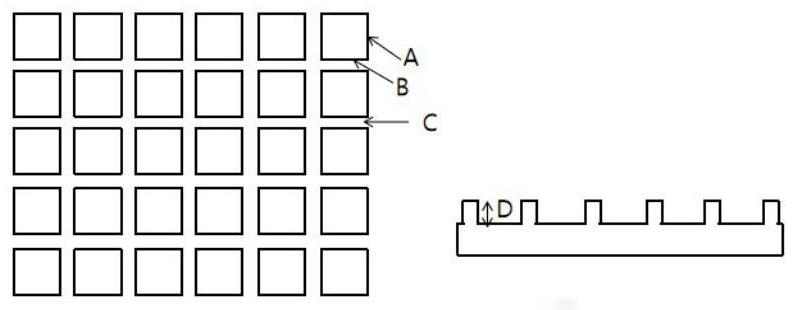

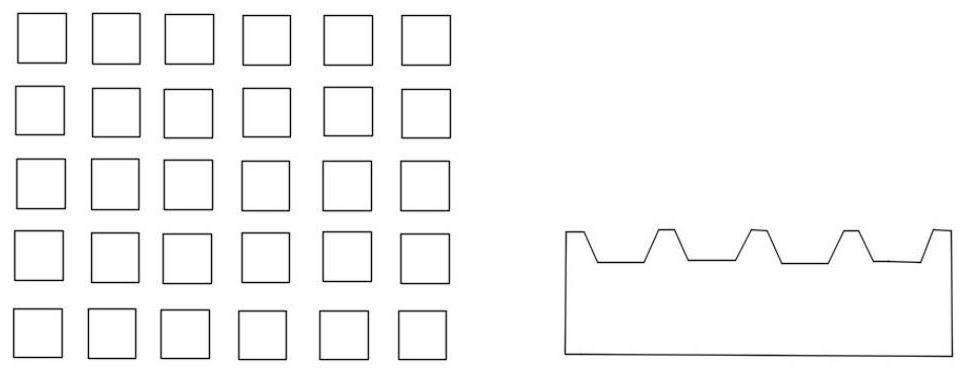

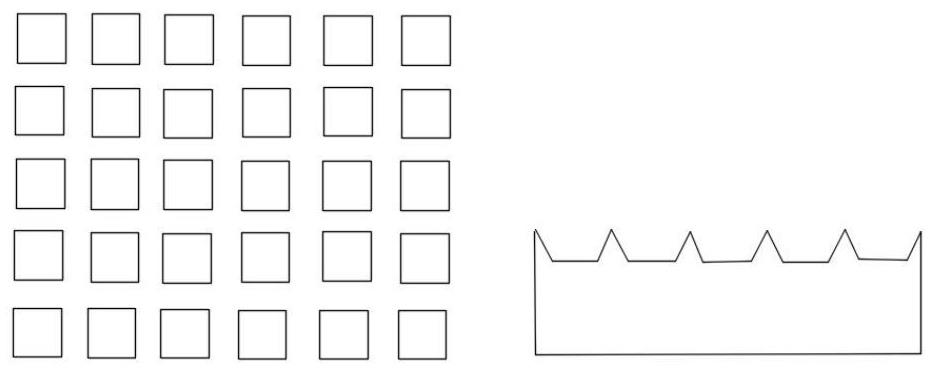

Image

Examples

Embodiment 1

[0045] A preparation method for fast leveling ultra-thin grid tape, comprising the following steps:

[0046] S1. In parts by mass, 100 parts of acrylic pressure-sensitive adhesive, 8 parts of tackifying resin, 1 part of curing agent, and 200 parts of solvent were mixed and stirred, and ultrasonically dispersed to obtain a coating mixture;

[0047] Acrylic pressure sensitive adhesive, glass transition temperature (Tg) at -15°C, weight average molecular weight M W It is 457800, the molecular weight distribution is 2.2; the normal temperature is 23°C, the storage modulus G' is 33086Pa, and the loss factor tanδ is 0.67; the high temperature is 85°C, the storage modulus G' is 10056Pa, and the loss factor tanδ is 0.61;

[0048] Tackifying resin is terpene resin; curing agent is polyisocyanate; solvent is ethyl acetate;

[0049] S2. Coating the coating mixture in step S1 on the release surface of the grid release film, drying and curing in 8 temperature zones, to obtain the pressure...

Embodiment 2

[0056] A preparation method for fast leveling ultra-thin grid tape, comprising the following steps:

[0057] S1. In parts by mass, 100 parts of acrylic pressure-sensitive adhesive, 12 parts of tackifying resin, 2 parts of curing agent, and 300 parts of solvent were mixed and stirred, and ultrasonically dispersed to obtain a coating mixture;

[0058] Acrylic pressure sensitive adhesive, glass transition temperature (Tg) at -30°C, weight average molecular weight M W It is 425100, the molecular weight distribution is 2.3; the normal temperature is 23°C, the storage modulus G' is 38021Pa, and the loss factor tanδ is 0.63; the high temperature is 85°C, the storage modulus G' is 12574Pa, and the loss factor tanδ is 0.63;

[0059] Tackifying resin is petroleum resin; curing agent is epoxy curing agent; solvent is toluene;

[0060] S2. Coating the coating mixture in step S1 on the release surface of the grid release film, drying and curing in 8 temperature zones, to obtain the pressu...

Embodiment 3

[0067] A preparation method for fast leveling ultra-thin grid tape, comprising the following steps:

[0068] S1. In parts by mass, 100 parts of acrylic pressure-sensitive adhesive, 25 parts of tackifying resin, 3 parts of curing agent, and 500 parts of solvent were mixed and stirred, and ultrasonically dispersed to obtain a coating mixture;

[0069] Acrylic pressure sensitive adhesive, glass transition temperature (Tg) at -34°C, weight average molecular weight M W It is 389100, the molecular weight distribution is 1.9; the normal temperature is 23°C, the storage modulus G' is 41245Pa, and the loss factor tanδ is 0.68; the high temperature is 85°C, the storage modulus G' is 13841Pa, and the loss factor tanδ is 0.64;

[0070] Tackifying resin is rosin resin; curing agent is polyisocyanate; solvent is toluene;

[0071] S2. Coating the coating mixture in step S1 on the release surface of the grid release film, drying and curing in 8 temperature zones, to obtain the pressure-sensi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| Storage modulus | aaaaa | aaaaa |

| Storage modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com