Method for producing structure body having super-hydrophobic surface

A super-hydrophobic, structural technology, applied in the field of materials, can solve the problems of high cost, surface structure pollution, poor adaptability, etc., to enhance high temperature stability and durability, increase wear resistance, and long wear resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

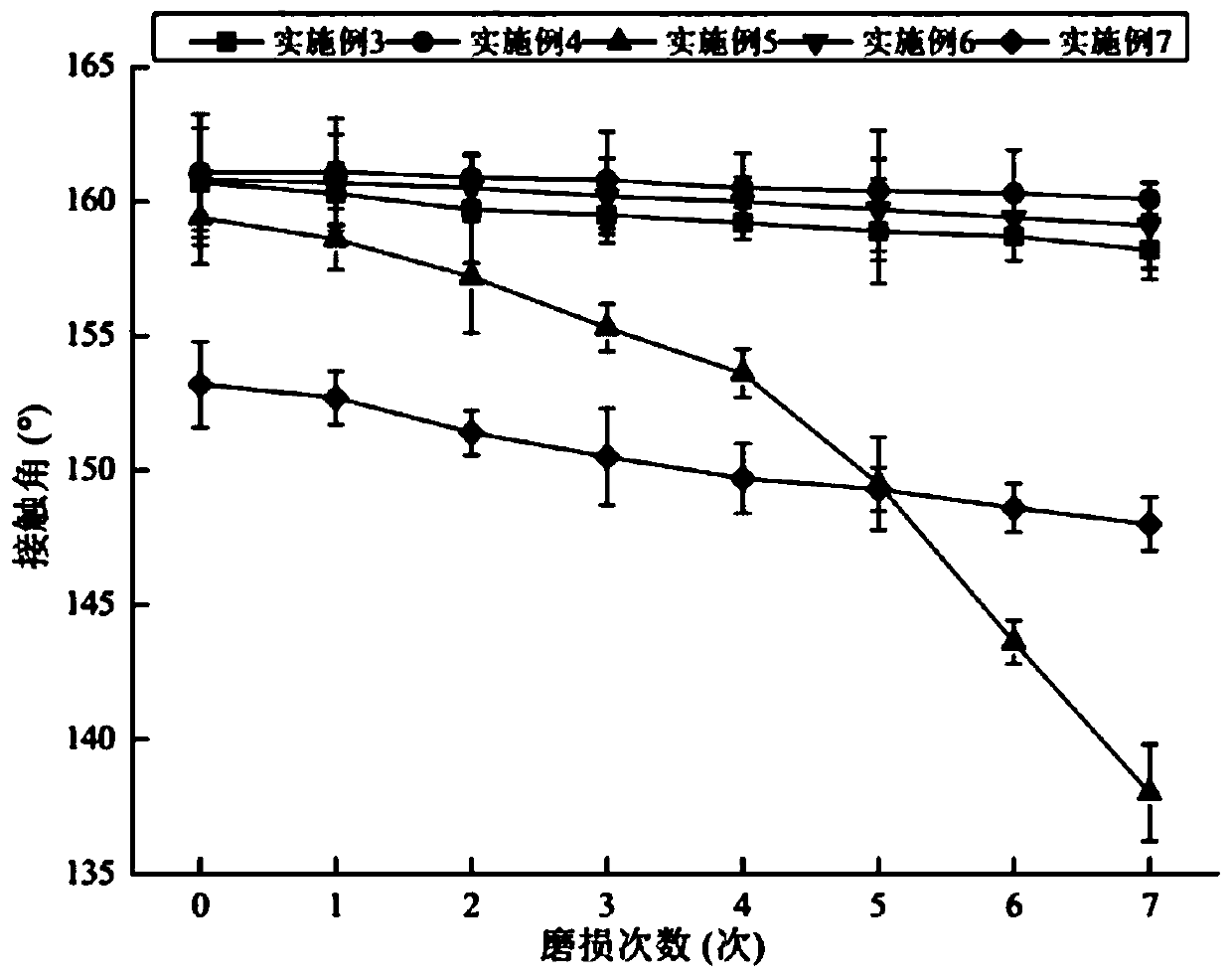

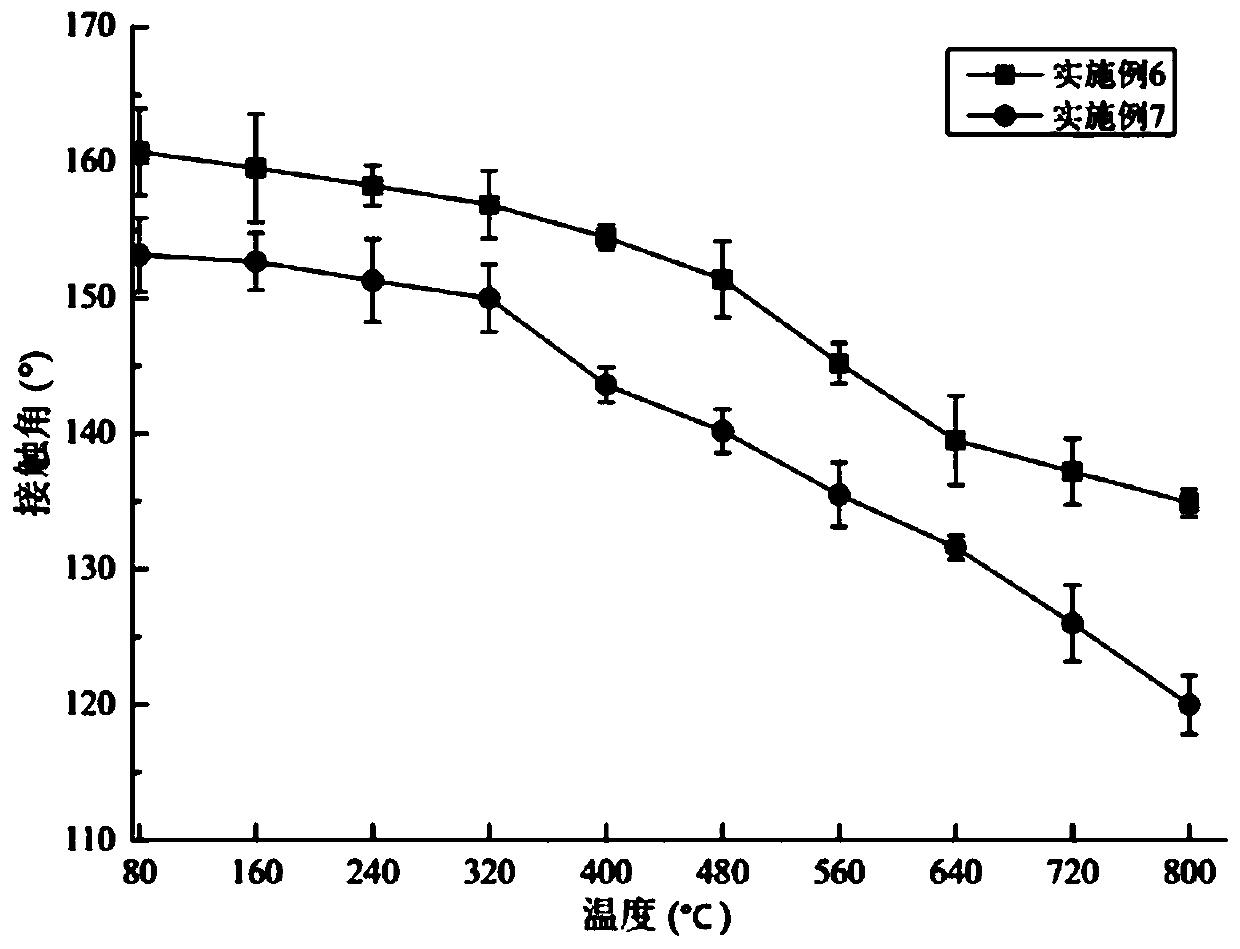

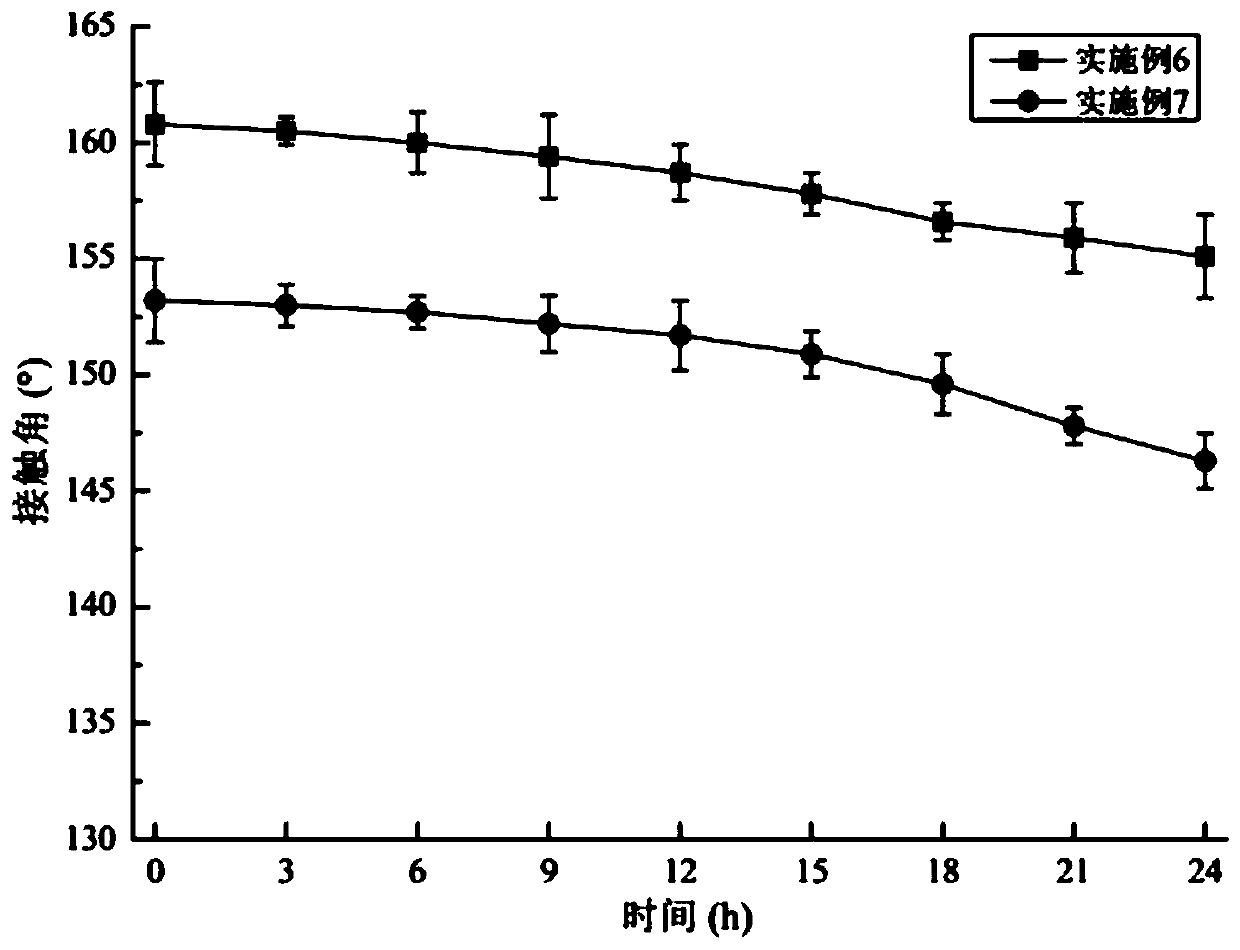

[0028] A method for preparing superhydrophobic powder, including: using nano-SiO 2 Particles as raw materials to prepare modified nano-SiO 2 Particles and SiO 2 Alcohol sol, above SiO 2 Alcohol sols include photocatalysts, the above-mentioned modified nano-SiO 2 particles by adding nano-SiO 2 The particles are prepared under the environment of modifying agent and gain agent, and the above-mentioned gain agent is diphenylethanolone and hexahydrophthalic anhydride; the superhydrophobic surface prepared by the above powder shows a contact angle of not less than 158° and less than 5 ° roll angle. This method improves the roughness of the superhydrophobic surface formed by the powder, increases the contact angle, and increases the wear resistance and high temperature stability of the superhydrophobic surface, which is conducive to strengthening the superhydrophobic surface or the structure with a superhydrophobic surface. The heat resistance, wear durability and service life o...

Embodiment 1

[0049] The preparation method of powder with superhydrophobicity, its specific steps are as follows:

[0050] (1) The raw materials are mixed in a weight ratio of tetraethyl orthosilicate: water: ammonia water: alcohol = 1:4.5:2.5:12, and then reacted at a temperature of 50°C for 6h to obtain dispersed nano-SiO 2 Particles, the above-mentioned alcohol is absolute ethanol, and the weight fraction of ammonia water is 25%;

[0051] (2) Take 1 / 4 nano-SiO 2 Particles were placed in 8 times the amount of ethanol, and then added with a concentration of 6.5wt% hydrochloric acid and TiO 2 , stir and disperse evenly, and then place it at 55°C for 35 hours to obtain SiO 2 Alcohol sol, the addition of the above hydrochloric acid is 8% of the weight of the nanoparticles, TiO 2 The amount is 20% of alcohol sol weight;

[0052] (3) Take the remaining 3 / 4 nano-SiO 2 Dissolve the particles in 5-10 times the amount of absolute ethanol, adjust the pH to 8, add the modifier phenyltrimethoxys...

Embodiment 2

[0055] The preparation method of the powder with superhydrophobic surface, the difference between this embodiment and embodiment 1 is: in step (3), prepare modified nano-SiO 2 The particles do not add the benefit agents benzyl ethanolone and hexahydrophthalic anhydride.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com