Composite cross arm and manufacturing process thereof

A manufacturing process and technology of cross-arm, applied in the field of new composite cross-arm and its manufacturing process, can solve the problems of non-insulation, operation accidents, low mechanical strength, etc., and achieve good mechanical properties, excellent weather resistance, and strong adhesion. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Below in conjunction with accompanying drawing, the present invention is described in further detail:

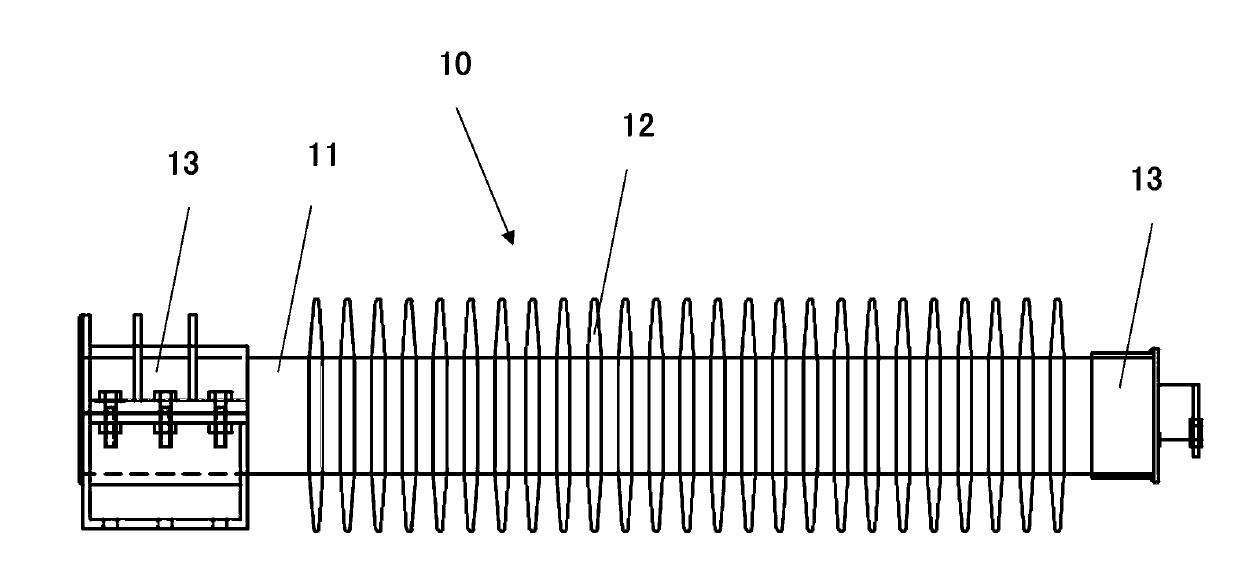

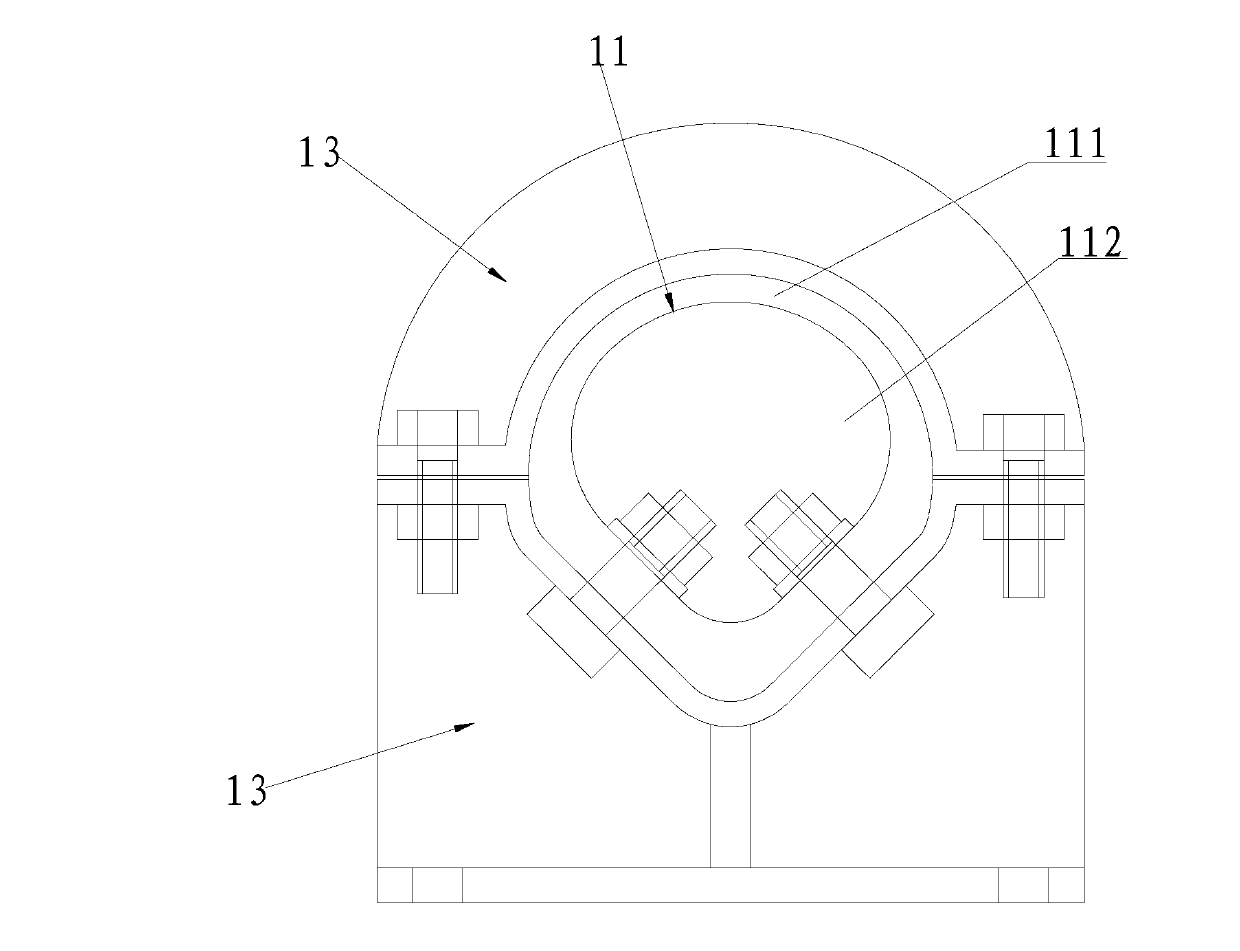

[0033] as attached figure 1 As shown, a composite cross arm 10 includes an insulating mandrel 11 , a shed 12 fixed on the insulating mandrel 11 , and connectors 13 fixedly connected to both ends of the insulating mandrel 11 . The fixture at one end of the connector 13 is used to fix the cross arm on the pole tower, and the fixture at the other end is used to hang the transmission wire. The cross-section of the insulating mandrel of the present invention is D-shaped, and compared with the solid or hollow cylindrical structure in the prior art, it has the advantages of anti-dust accumulation and convenient installation.

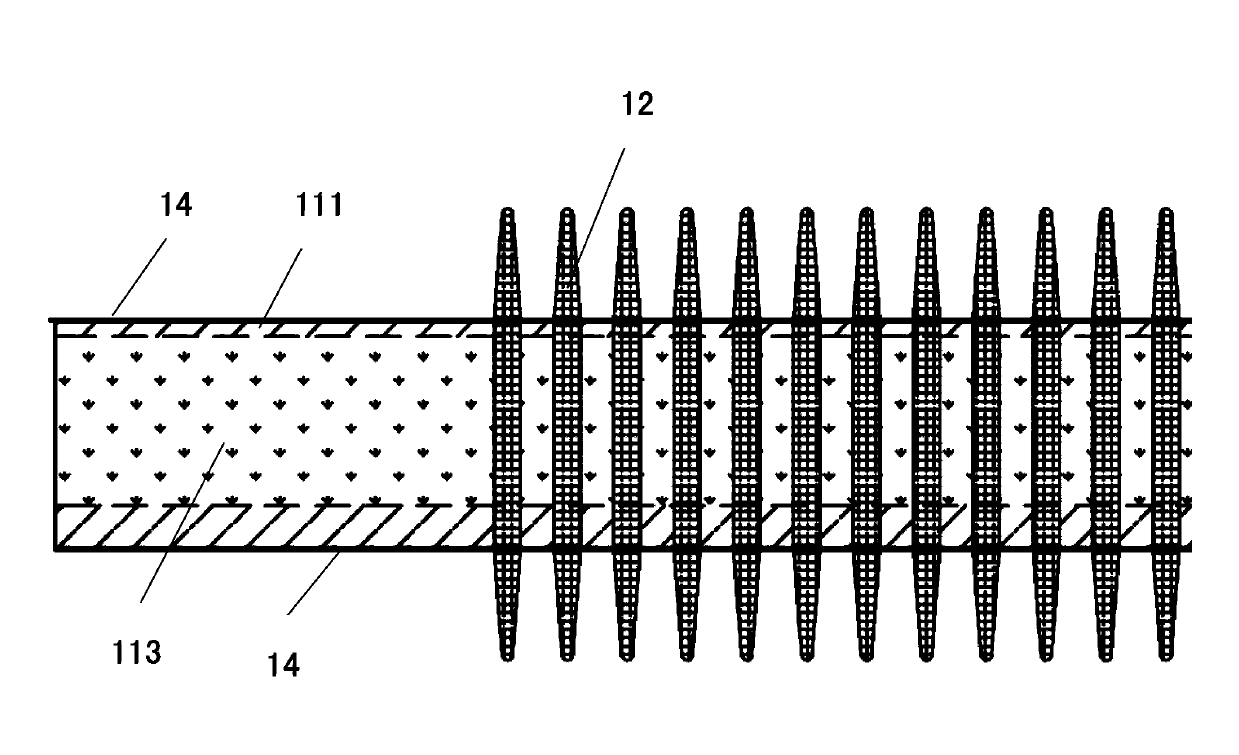

[0034] The insulating mandrel 11 is manufactured through a pultrusion winding process, and is a new type of resin fiber composite layer structure, which has the characteristics of light weight and high strength. The composite layer 111 in this embodi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com