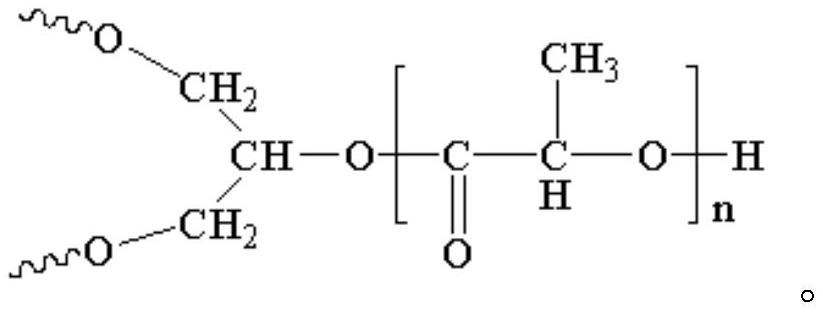

A heat-resistant and impact-resistant highly transparent polylactic acid composite material and its preparation method

A composite material, polylactic acid technology, which is applied in the field of heat-resistant and impact-resistant high-transparency polylactic acid composite materials and its preparation, can solve the problems that modified polylactic acid resin cannot simultaneously take into account transparency, heat resistance, and impact resistance. Achieve the effect of guaranteeing service life, improving crystallization speed and good impact strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

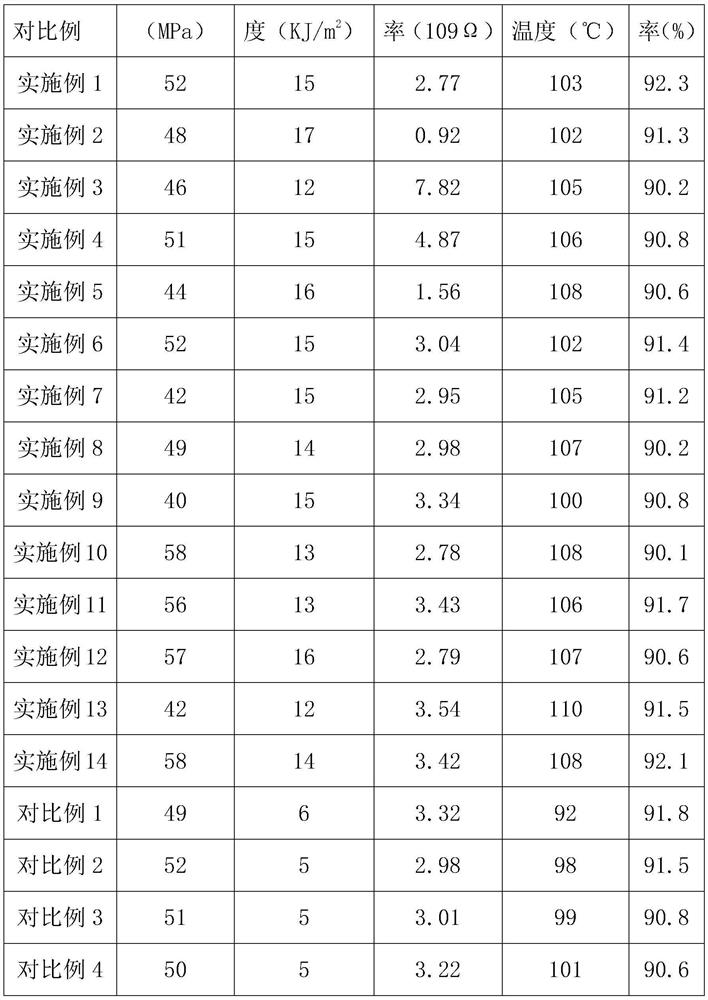

Examples

Embodiment 1

[0036] This embodiment provides a heat-resistant and impact-resistant high-transparency polylactic acid composite material, comprising the following components by weight: 100 parts of three-arm branched polylactic acid (number average molecular weight is 50,000), 2 parts of toughening agent polybutylene Butylene glycol ester, 0.2 part of chain extender styrene-methyl methacrylate-glycidyl methacrylate terpolymer random copolymer, 0.5 part of crystallization nucleating agent poly-D lactic acid powder, 0.03 part of crystallization accelerator 1,3:2,4-bis(3,4-dimethyl)benzylidene sorbitol acetal, 0.6 part of antistatic agent bis(β-hydroxyethyl)cocamide.

[0037] The preparation method of the heat-resistant and impact-resistant high-transparency polylactic acid composite material:

[0038] Dry the three-arm branched polylactic acid in vacuum at 60°C for 10 hours until the water content is lower than 300ppm;

[0039] Uniformly blend the dried polylactic acid with toughening agent,...

Embodiment 2

[0044] This embodiment provides a heat-resistant and impact-resistant high-transparency polylactic acid composite material, comprising the following components by weight: 100 parts of five-arm branched polylactic acid (number average molecular weight is 200,000), 5 parts of toughening agent polybutylene Butylene glycol ester, 0.5 parts of chain extender styrene-methyl methacrylate-glycidyl methacrylate terpolymer random copolymer, 1 part of crystallization nucleating agent poly-D lactic acid powder, 0.01 part of crystallization accelerator Tribenzylidene Diester Hexanol, 1 part Antistatic Bis(β-Hydroxyethyl) Cocoamine.

[0045] The preparation method of the heat-resistant and impact-resistant high-transparency polylactic acid composite material:

[0046] Dry the three-arm branched polylactic acid in vacuum at 90°C for 6 hours until the water content is lower than 300ppm;

[0047] Uniformly blend the dried polylactic acid with toughening agent, chain extender, crystallization ...

Embodiment 3

[0052] This embodiment provides a heat-resistant and impact-resistant high-transparency polylactic acid composite material, comprising the following components by weight: 100 parts of three-arm branched polylactic acid (number average molecular weight is 100,000), 1 part of toughening agent polybutylene Butylene glycol ester, 0.1 part of chain extender styrene-methyl methacrylate-glycidyl methacrylate terpolymer random copolymer, 0.01 part of crystallization nucleating agent poly-D lactic acid powder, 0.05 part of crystallization accelerator Neopentyl glycol biphenyl ester, 0.1 parts of antistatic agent bis(β-hydroxyethyl) cocoamine.

[0053] The preparation method of the heat-resistant and impact-resistant high-transparency polylactic acid composite material:

[0054] Dry the three-arm branched polylactic acid in vacuum at 80°C for 8 hours until the water content is lower than 300ppm;

[0055] Uniformly blend the dried polylactic acid with toughening agent, chain extender, c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com