Fluorescent tube with reflection shielding film on backward tube wall

A technology for fluorescent tubes and tubes, applied in the field of fluorescent tubes, can solve the problems of loss of reflective lighting function and effect, reduction, etc., and achieve the effects of easy popularization and application, high-efficiency reflective shielding function, and enhanced brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

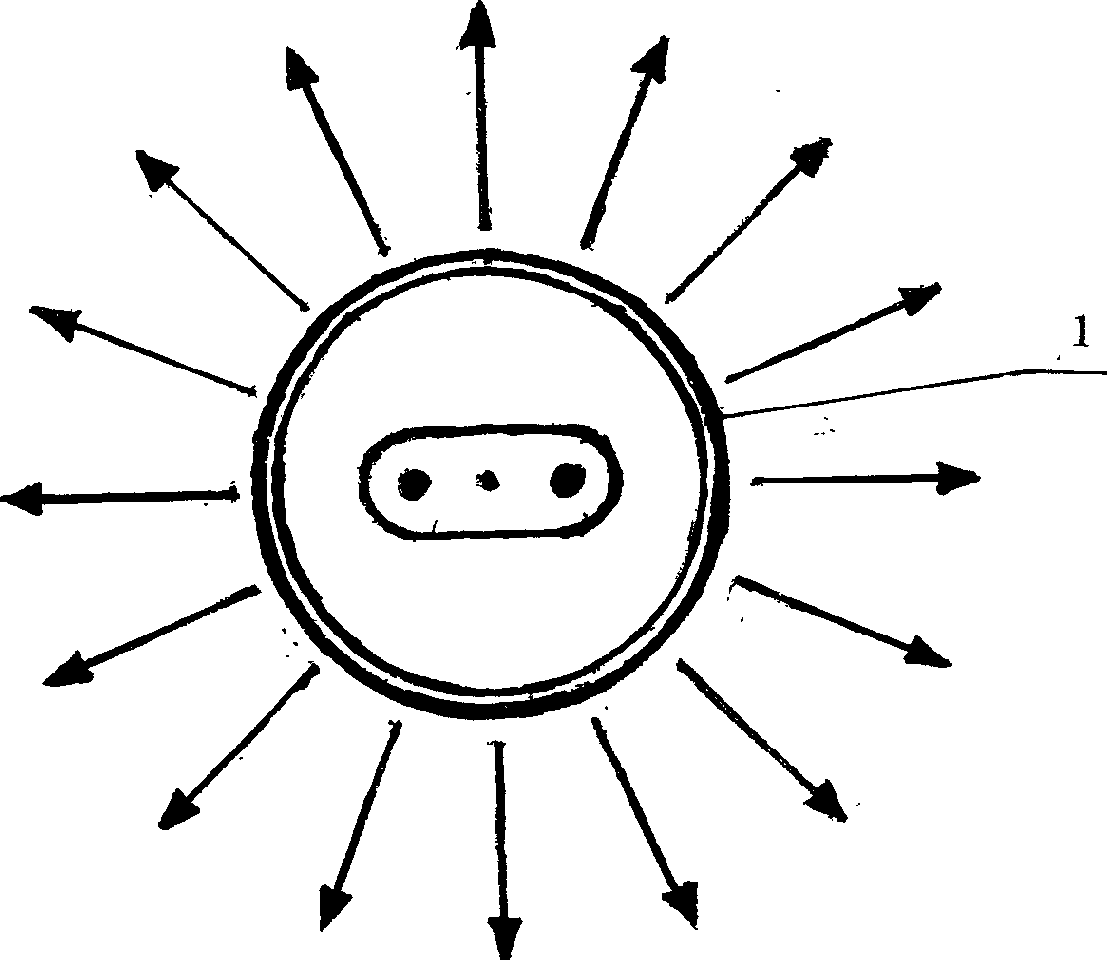

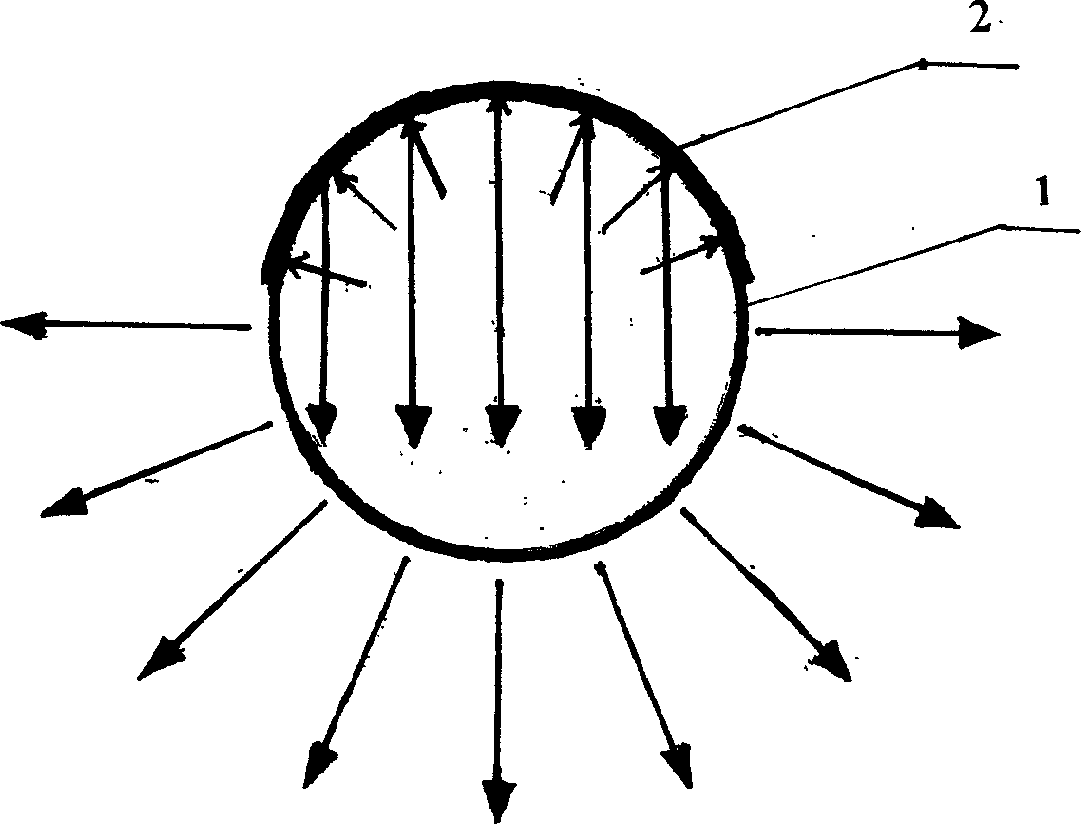

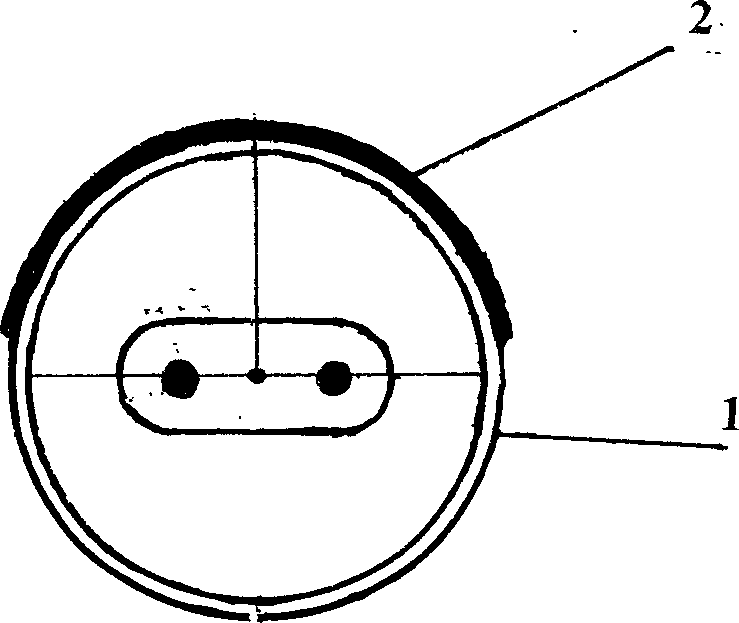

[0021] One of the most common installation methods for straight fluorescent tubes is: the lamp pin bracket is fixed in the direction of the ceiling, and when the front of the lamp tube body faces the direction of the lamp tube wall to illuminate the ground, the filament lead-out terminals and lamp pins at both ends of the lamp tube The jack is in a horizontal position, and the line of the vertical bisector of its filament terminal line coincides with the center line of the reflective shielding film set on the outer surface of the lamp tube wall. Such as image 3 As shown, as the uniform standard setting position of the reflective shielding film on the outer surface of the fluorescent tube wall facing away from the universal type of fluorescent tube, it is also most suitable for the lamination process of the straight fluorescent tube to paste the mirror reflec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com