A kind of fluorinated polyether siloxane compound, its preparation method and coating composition

A technology of fluorinated polyether siloxane and siloxane compound, used in polyurea/polyurethane coatings, antifouling/underwater coatings, coatings, etc. Improve adhesion and wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

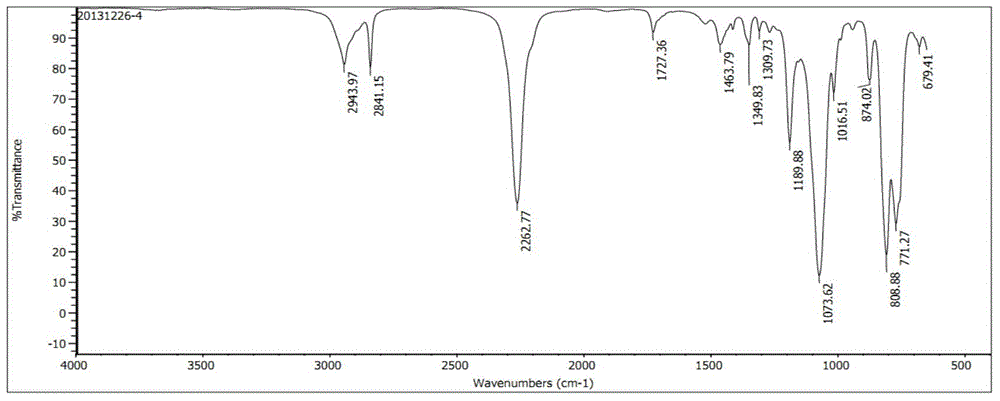

[0085] Fluorinated Polyether Silicone CompoundsX 1 preparation of

[0086]The first step of reaction: Put Fluorolink1500 (15g, 0.01mol) and HDI (0.84g, 0.005mol) into the installed magnetic stirrer and 100ml Erlenmeyer flask, heat the mixture to 60°C and keep it for 4 hours , to obtain the initial product HOCH 2 CF 2 O(CF 2 CF 2 O) p (CF 2 O) q CF 2 CH 2 OCONH(CH 2 ) 6 HNOCOCH 2 CF 2 (CF 2 O) q (OCF 2 CF 2 ) p OCF 2 CH 2 OH, where p is 8 and q is 9, the completion of the reaction is determined by titrating the isocyanate value.

[0087] The second step reaction: After the first step reaction is completed, add 3-isocyanate propyl trimethoxysilane (8.20 g, 0.04 mol) and add 0.0015 g of catalyst tetrabutyl titanate, and heat the mixture to 60°C. And keep it for 6 hours, and determine the completion of the reaction by titrating the hydroxyl value. After the reaction is completed, 50ml of isopropanol can be used for separation to obtain the product X 1 :

[...

Embodiment 2

[0091] Fluorinated Polyether Silicone CompoundsX 2 preparation of

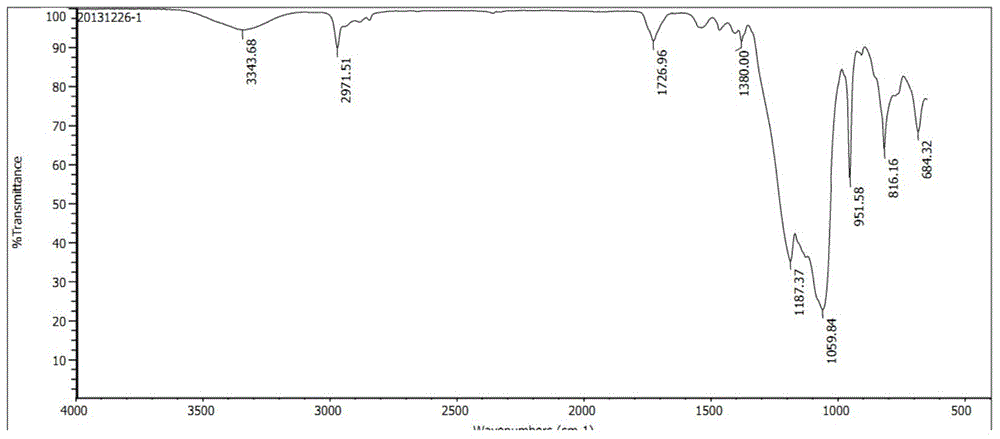

[0092] The first step of reaction: put Fluorolink2500 (25g, 0.01mol) and HDI (0.84g, 0.005mol) into the installed magnetic stirrer and 100ml Erlenmeyer flask, the mixture is heated to 60°C and kept for 4 hours, The initial product was obtained: HO(CH 2 CH 2 O) m CH 2 CF 2 O(CF 2 CF 2 O) p (CF 2 O) q CF 2 CH 2 (OCH 2 CH 2 ) m OCONH(CH 2 ) 6 HNO CO(CH 2 CH 2 O) m CH 2 CF 2 (OCF 2 ) q (OCF 2 CF 2 ) P OCF 2 CH 2 (OCH 2 CH 2 ) m OH, where p is 10, q is 12, and m is 8, the completion of the reaction is determined by titrating the isocyanate value.

[0093] The second step reaction: After the first step reaction is completed, 3-isocyanate propyl trimethoxysilane (8.2 g, 0.04 mol) is added, and the catalyst tetra-n-butyl titanate is added, the mixture is heated to 60 ° C, and Keep it for 6 hours, and determine the completion of the reaction by titrating the hydroxyl value. After the ...

Embodiment 3

[0095] Fluorinated Polyether Silicone CompoundsX 3 preparation of

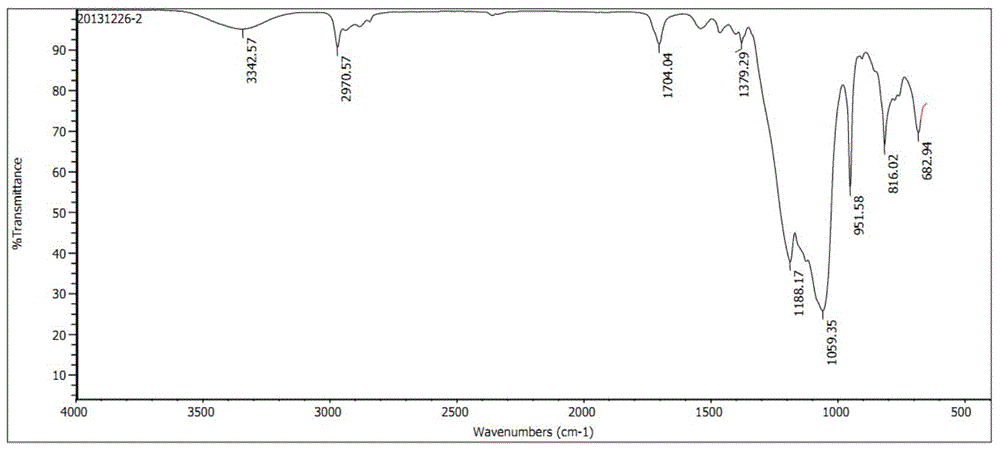

[0096] The first step of reaction: In the installed magnetic stirrer and 100ml Erlenmeyer flask, put Fluorolink1500 (15 grams, 0.01mol) and IPDI (1.11 grams, 0.005mol), the mixture is heated to 60 ° C, and kept for 6 hours, The completion of the reaction was determined by titrating the isocyanate value.

[0097] The second reaction: After the first step reaction is completed, 3-isocyanate propyltrimethoxysilane (8.2 g, 0.04 mol) is added, and the catalyst dibutyltin dilaurate is added, and the mixture is heated to 60 ° C and kept for 8 Hours, the completion of the reaction was determined by titrating the hydroxyl value. After the reaction is completed, 50ml of isopropanol can be used for separation to obtain the product X 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com