Lignin-unsaturated carboxylate composite reinforcing agent and application thereof in rubber

A lignin and unsaturated technology, applied in the technical field of superfine powder for reinforcement and the field of rubber composite materials, can solve the problems of large intermolecular force, unfavorable rubber reinforcement, and difficulty in dispersion, etc. The effect of reducing force and improving dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

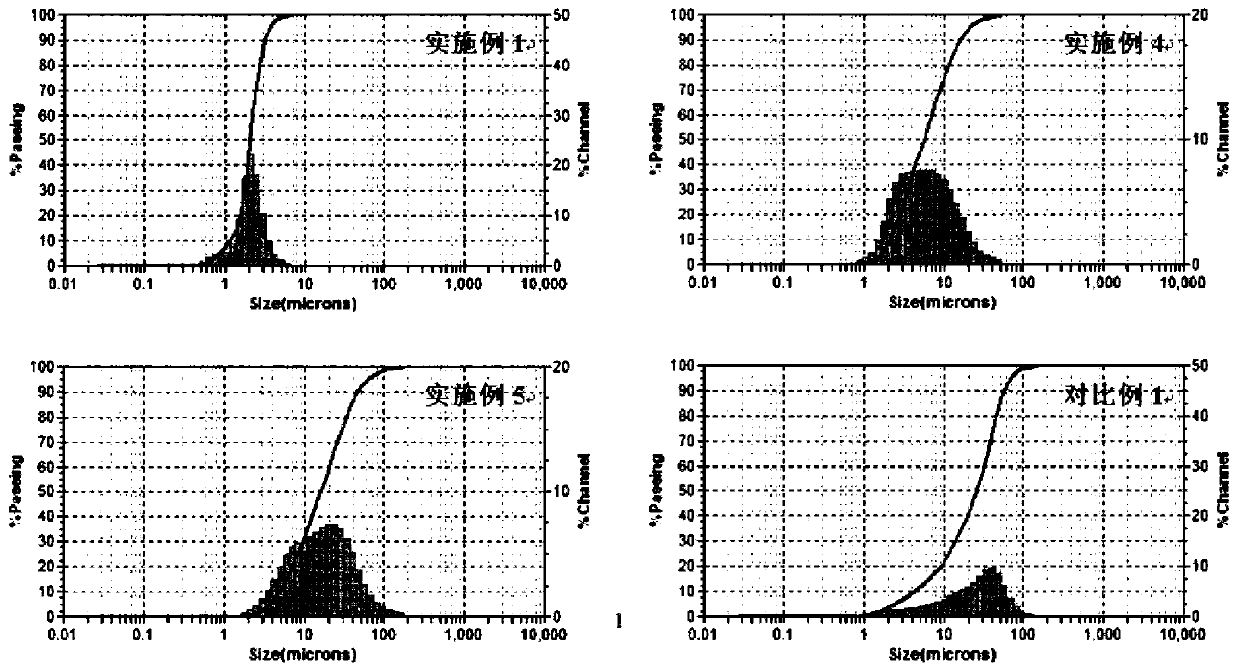

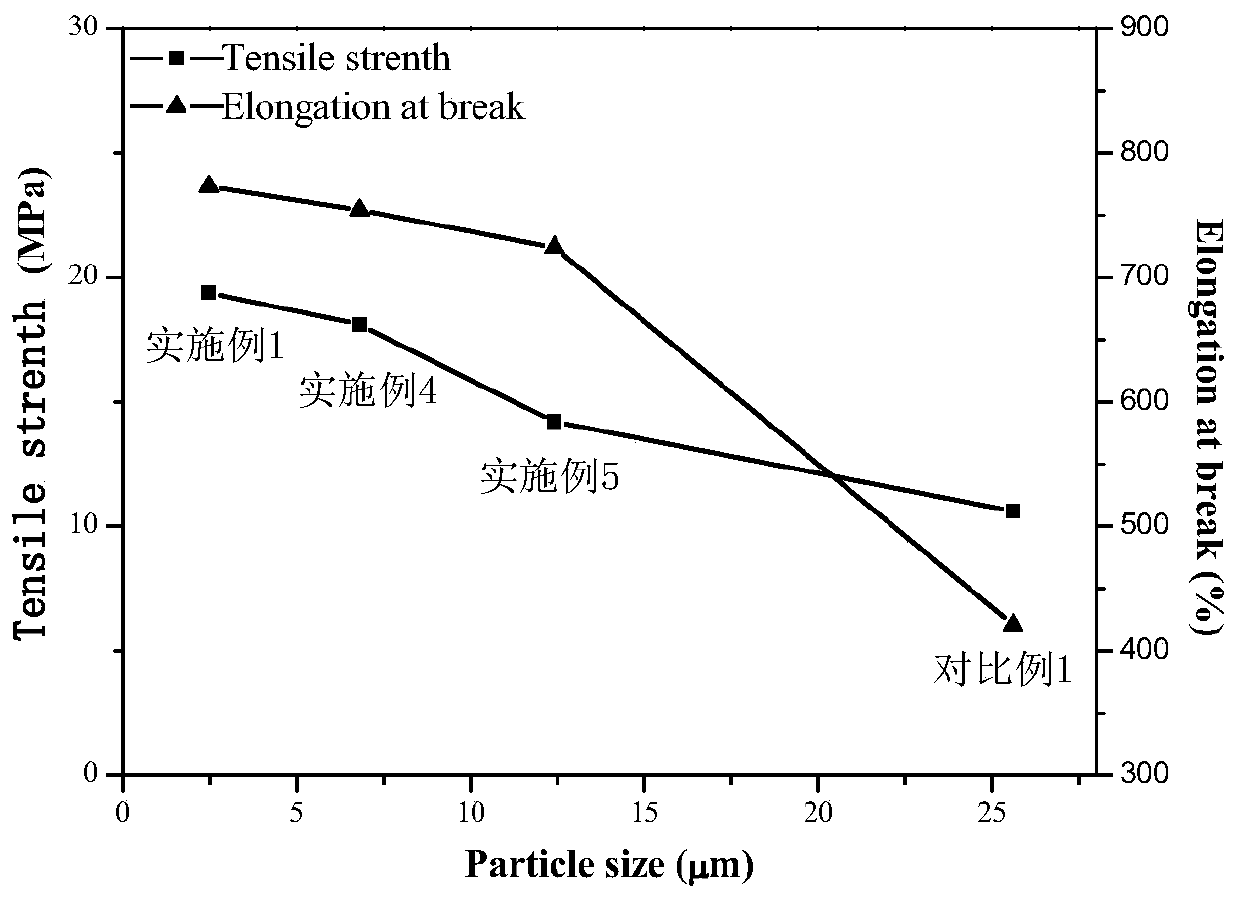

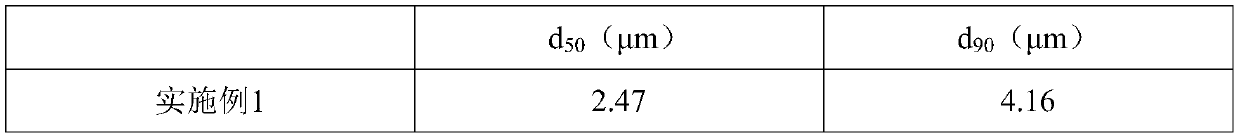

Embodiment 1

[0033] (1) Mix and stir eucalyptus lignin and zinc methacrylate at a mass ratio of 100:5, and inject 0.8Mpa compressed air into the jet mill at the same time, and put the pulverized material into the classification chamber for classification, and the submachine speed is 8000rpm / min, return the classified material with a mesh number <3000 mesh to the jet mill for re-crushing, and discharge the classified mesh mesh ≥3000 mesh material from the discharge port to obtain a lignin-zinc methacrylate composite reinforcing agent;

[0034] (2) Weigh 10g of the composite reinforcing agent obtained in step (1), mix it with 40g of natural rubber, 10g of high wear-resistant carbon black N330, 1g of sulfur, 0.6g of N-cyclohexyl-2-benzothiazole sulfenamide, 2g of oxidation Add zinc and 0.8g stearic acid to the internal mixer in turn, and banbury at 100°C for 20 minutes;

[0035] (3) Place the mixed rubber obtained in step (2) in an open mill and pass it 7 times to lower the sheet, measure it...

Embodiment 2

[0037] (1) Mix and stir eucalyptus lignin and zinc methacrylate at a mass ratio of 100:10, and inject 0.8Mpa compressed air into the jet mill at the same time, and put the pulverized material into the classification chamber for classification, and the submachine speed is 8000rpm / min, return the classified material with a mesh number <3000 mesh to the jet mill for re-crushing, and discharge the classified mesh mesh ≥3000 mesh material from the discharge port to obtain a lignin-zinc methacrylate composite reinforcing agent;

[0038] (2) Weigh 10g of the composite reinforcing agent obtained in step (1), mix it with 40g of natural rubber, 10g of high wear-resistant carbon black N330, 1g of sulfur, 0.6g of N-cyclohexyl-2-benzothiazole sulfenamide, 2g of oxidation Add zinc and 0.8g stearic acid to the internal mixer in turn, and banbury at 100°C for 20 minutes;

[0039] (3) Place the mixed rubber obtained in step (2) in an open mill and pass it 7 times to lower the sheet, measure i...

Embodiment 3

[0041](1) Mix and stir eucalyptus lignin and zinc methacrylate at a mass ratio of 100:20, and inject 0.8Mpa compressed air into the jet mill at the same time, and put the pulverized material into the classification chamber for classification, and the submachine speed is 8000rpm / min, return the classified material with a mesh number <3000 mesh to the jet mill for re-crushing, and discharge the classified mesh mesh ≥3000 mesh material from the discharge port to obtain a lignin-zinc methacrylate composite reinforcing agent;

[0042] (2) Weigh 10g of the composite reinforcing agent obtained in step (1), mix it with 40g of natural rubber, 10g of high wear-resistant carbon black N330, 1g of sulfur, 0.6g of N-cyclohexyl-2-benzothiazole sulfenamide, 2g of oxidation Add zinc and 0.8g stearic acid to the internal mixer in turn, and banbury at 100°C for 20 minutes;

[0043] (3) Place the mixed rubber obtained in step (2) in an open mill and pass it 7 times to lower the sheet, measure it...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com