Preparation method of spinnable mesophase pitch

A technology for mesophase pitch and petroleum pitch, which is applied in the field of preparation of spinnable mesophase pitch, can solve the problems of cumbersome operation process, harsh equipment conditions, high hydrogenation reaction pressure, etc., and achieves the effect of good equipment adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

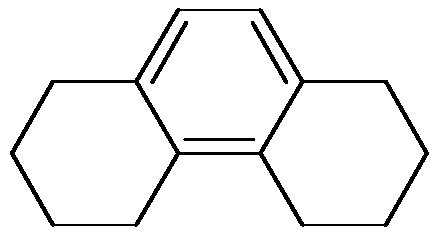

Image

Examples

preparation example Construction

[0039] The preparation method of the spinnable mesophase pitch of the present invention is prepared by purging the petroleum pitch with high aromaticity and high softening point as raw material, reacting with the high-boiling-point hydrogen-donating agent octahydrophenanthrene under lower pressure, and purging at normal pressure Spinnable mesophase pitch. Specifically include the following steps:

[0040] (1) After pulverizing the high-quality petroleum asphalt with a softening point of 110-150°C, use toluene as a solvent for thermal extraction, the extraction temperature is 110°C, and the mass ratio of the toluene solvent to the processed high-quality petroleum asphalt is ( 4~8):1, preferably 6:1. After the extraction is completed, the extract is filtered while it is hot, and the filtrate is distilled under reduced pressure to recover the solvent, and the obtained asphalt is purified petroleum asphalt.

[0041] The petroleum pitch with a softening point of 110-150°C should ...

Embodiment 1

[0049] Crush petroleum asphalt with a softening point of 120°C and an aromaticity of 86%, heat extraction with toluene with 6 times the mass of petroleum asphalt at 110°C, filter the extract with a sand core funnel after extraction, and distill the filtrate under reduced pressure to obtain Purify petroleum asphalt. The yield of purified petroleum asphalt is about 93%.

[0050] Put the purified petroleum asphalt into the high-pressure reaction kettle, add 10% pure octahydrophenanthrene of purified petroleum asphalt, and use high-purity nitrogen to replace the air after locking the kettle, and pressurize 0.4MPa, gradually raise the temperature to 400°C for 8 hours, and the stirring speed It is 300rpm, and the maximum pressure of the control system in the process does not exceed 1.8MPa.

[0051] The pressure of the system was released to close to normal pressure within 30 minutes, that is less than 0.1MPa, the stirring rate was adjusted to 250rpm, the system temperature was lowe...

Embodiment 2

[0056] Crush petroleum asphalt with a softening point of 120°C and an aromaticity of 86%, heat extraction with toluene with 8 times the mass of petroleum asphalt at 110°C, filter the extract with a sand core funnel after extraction, and distill the filtrate under reduced pressure to obtain Purify petroleum asphalt. The yield of purified petroleum asphalt is about 96%.

[0057] Put the purified petroleum asphalt into the autoclave, add 5% pure octahydrophenanthrene of purified petroleum asphalt, lock the kettle, use argon to replace the air, and pressurize 0.5MPa, gradually raise the temperature to 420°C for 6 hours, and the stirring rate is 300rpm, the maximum pressure of the control system in the process does not exceed 1.5MPa.

[0058] The system pressure was released to close to normal pressure within 30 minutes, the stirring rate was adjusted to 250 rpm, the system temperature was lowered to 410°C, and nitrogen purge was started at a flow rate of 8 L / (kg·min) for 4 hours....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com