Antibacterial sanitary mobile phone film and preparation method thereof

A mobile phone film and hygienic technology, which is applied in the field of antibacterial and hygienic mobile phone film and its preparation, can solve the problems of affecting the service life of mobile phones, being fragile and not resistant to scratches, and easily breeding various bacteria.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

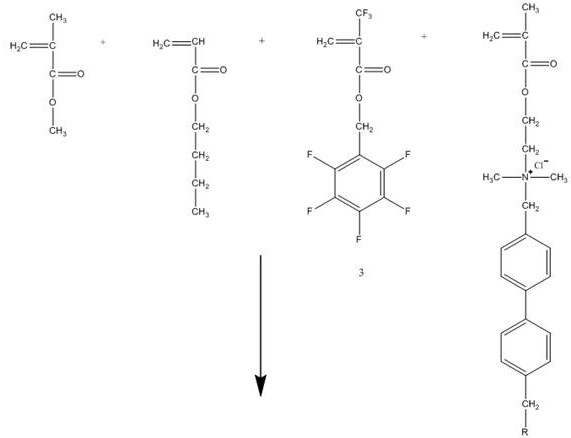

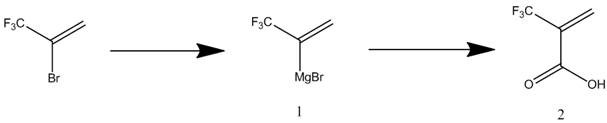

[0047] Present embodiment is a kind of preparation method of antibacterial antifouling emulsion, comprises the following steps:

[0048] A1: Add 150mL of tetrahydrofuran, 3.0g of magnesium powder, and 15.4g of 2-bromopropane into a three-necked flask equipped with a stirrer, a constant pressure dropping funnel, and an airway, and pass in nitrogen protection, at room temperature and at a stirring rate of 200r / min The reaction was stirred for 2h under the condition of , then 5.2g of anhydrous lithium chloride was added, and the stirring was continued for 5min, and then 40mL of 2-bromo-3,3,3-trifluoropropene solution was added dropwise at -60°C, 2 -Bromo-3,3,3-trifluoropropene solution is a solution formed by dissolving 2-bromo-3,3,3-trifluoropropene in tetrahydrofuran according to 44g:100mL, and the dropping rate is controlled at 1mL / min. After the completion, the reaction was stirred at a constant temperature for 2 hours to obtain intermediate 1, and then carbon dioxide gas was...

Embodiment 2

[0054] Present embodiment is a kind of preparation method of antibacterial antifouling emulsion, comprises the following steps:

[0055] A1: Add 150mL of tetrahydrofuran, 3.0g of magnesium powder, and 15.4g of 2-bromopropane into a three-necked flask equipped with a stirrer, a constant pressure dropping funnel, and an airway, and pass in nitrogen protection, at room temperature and at a stirring rate of 300r / min The reaction was stirred for 3h under the condition of , then 5.2g of anhydrous lithium chloride was added, and the stirring was continued for 10min, and then 40mL of 2-bromo-3,3,3-trifluoropropene solution was added dropwise at -60°C, 2 -Bromo-3,3,3-trifluoropropene solution is a solution formed by dissolving 2-bromo-3,3,3-trifluoropropene in tetrahydrofuran according to 44g:100mL, and the rate of addition is controlled at 2mL / min. After the completion, the reaction was stirred at a constant temperature for 3 hours to obtain intermediate 1, and then carbon dioxide gas...

Embodiment 3

[0061] This embodiment is a preparation method of an antibacterial and hygienic mobile phone film, comprising the following steps:

[0062] Step 1: Weigh 40 parts of antibacterial and antifouling emulsion from Example 1, 1 part of curing agent, 5 parts of cosolvent, 5 parts of deionized water, 3 parts of film-forming aid, and 1.5 parts of leveling agent according to parts by weight , 1.5 parts of coupling agent and 0.5 parts of defoamer, set aside;

[0063] Step 2: Add the antibacterial and antifouling emulsion into the mixer, add curing agent and co-solvent under the condition of stirring speed of 800r / min, continue to shear for 20min, then add deionized water, film-forming aid, leveling agent in sequence The agent and the coupling agent continue to shear for 1 hour, then add the defoamer and stir for 10 minutes under the condition that the stirring speed is 100 r / min, then let it stand for 2 hours, and filter to obtain the antibacterial sanitary coating;

[0064] Step 3: Pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com