Continuous powder coating production equipment of metal coils and plates and production method thereof

A technology for metal coils and production equipment, applied in liquid spraying equipment, coatings, spray discharge devices, etc., can solve the problems of inability to continuously spray electrostatic powder, low efficiency, and low production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

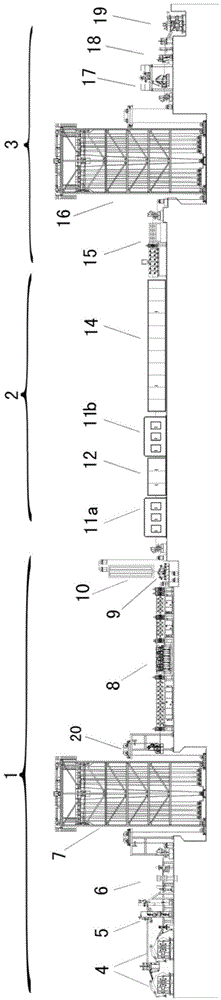

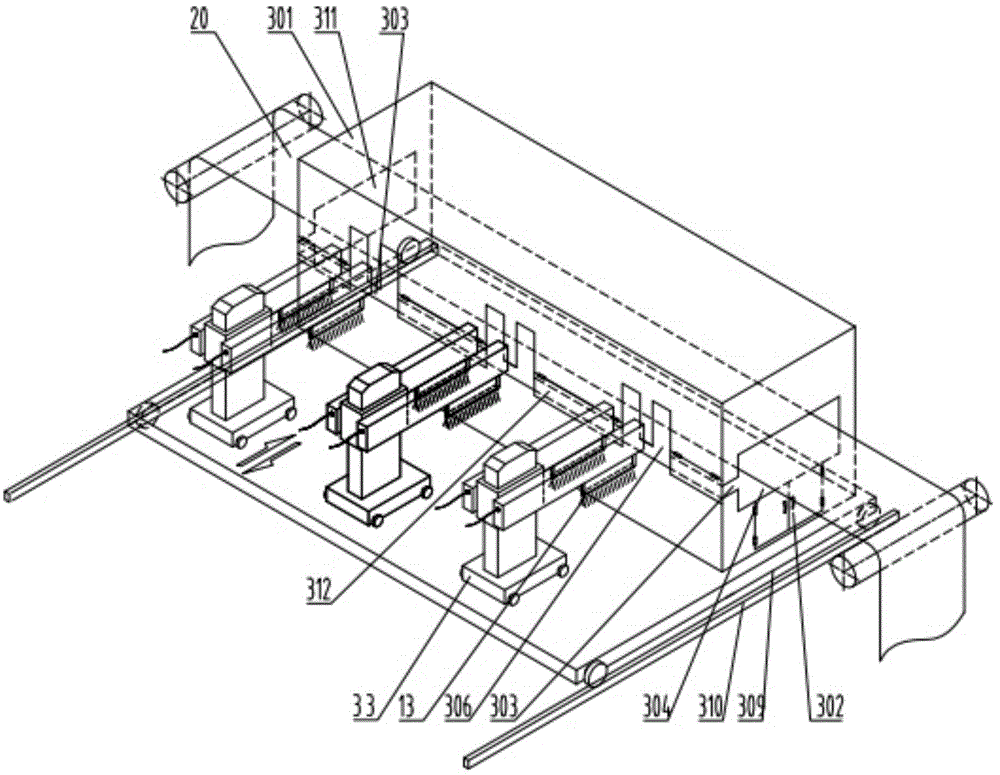

[0113] The continuous powder coating production equipment for metal coils and plates and the production method thereof of the present invention will be further described in conjunction with the accompanying drawings.

[0114] see figure 1 , is the continuous powder coating production equipment for metal coils and plates according to the present invention, including an inlet unit 1 , a coating curing unit 2 and an outlet unit 3 arranged continuously on the production line of the coated substrate 20 .

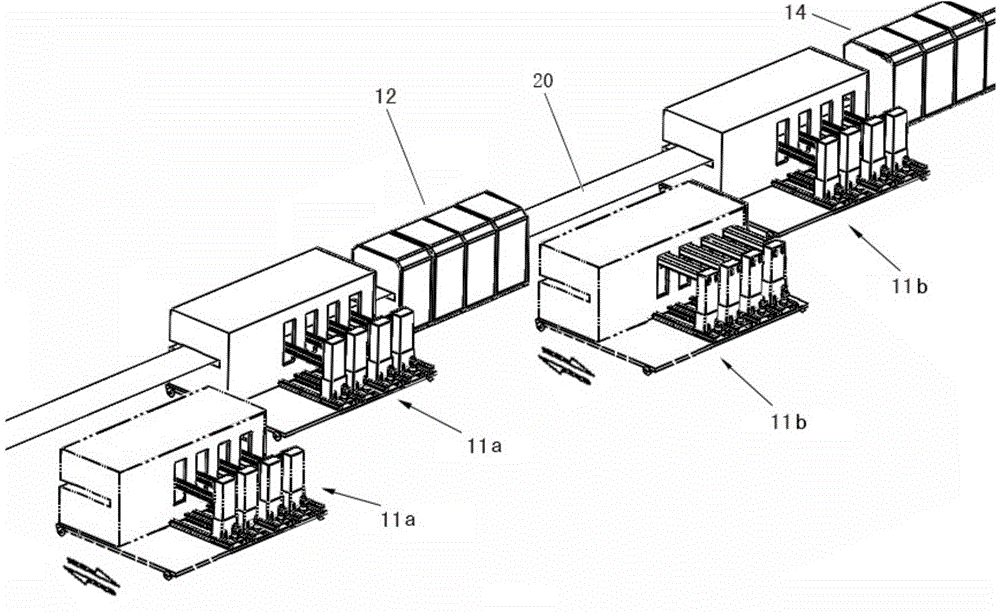

[0115] In order to realize the continuous electrostatic powder spraying production of different colors on the upper and lower surfaces of the coated substrate, see figure 2 , the production spraying group includes a first set of production spraying group 11a and a second set of production spraying group 11b, a coating preheating furnace 12 is arranged between the two sets of production spraying groups 11a, 11b, and the coating curing furnace 14 is arranged adjacent to the secon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com