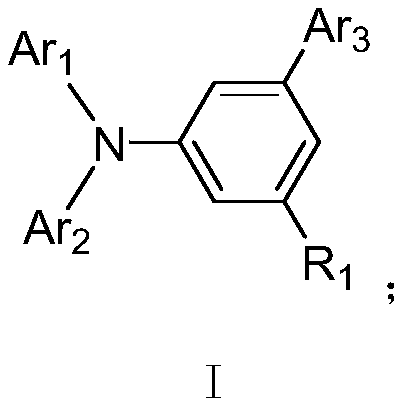

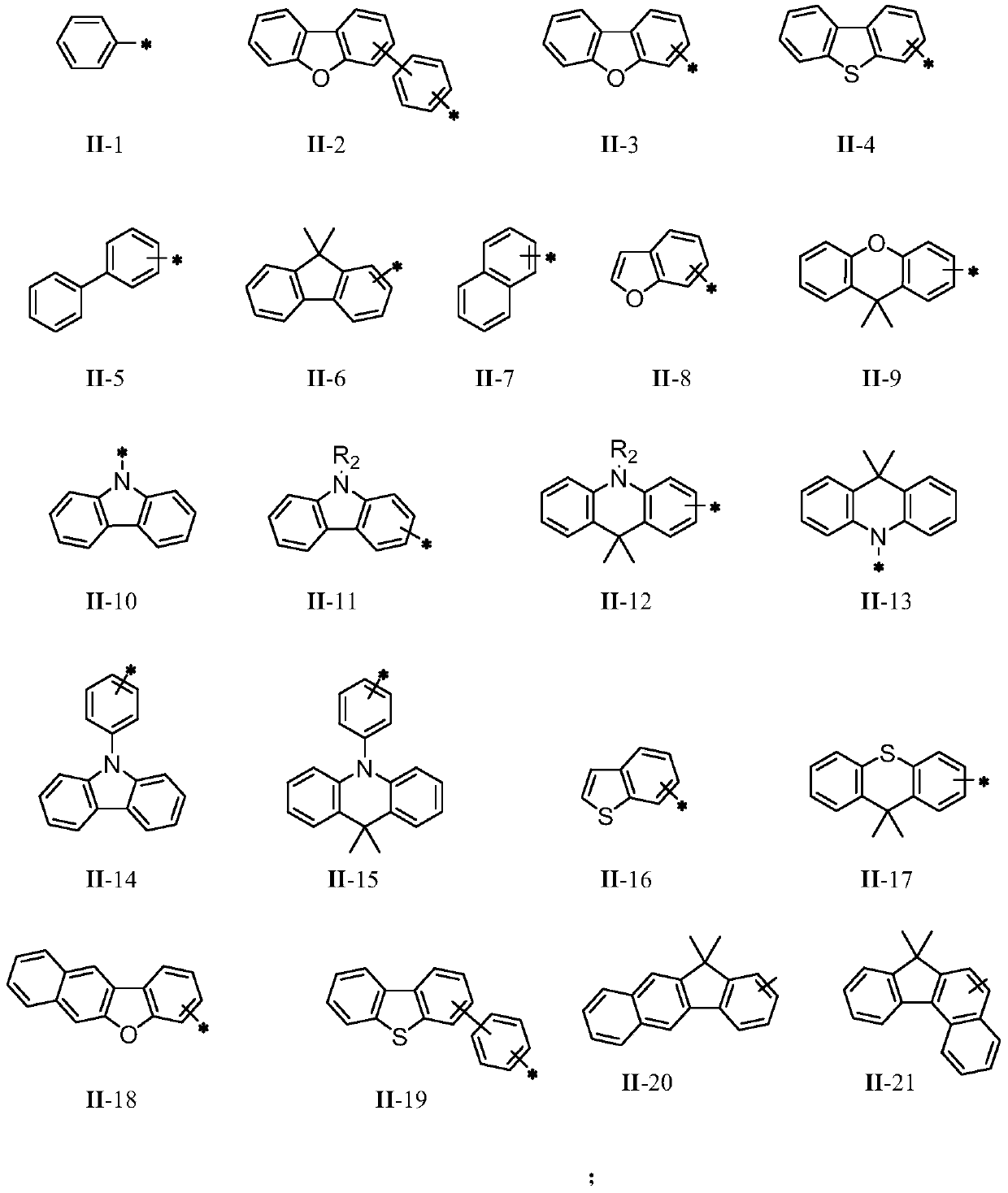

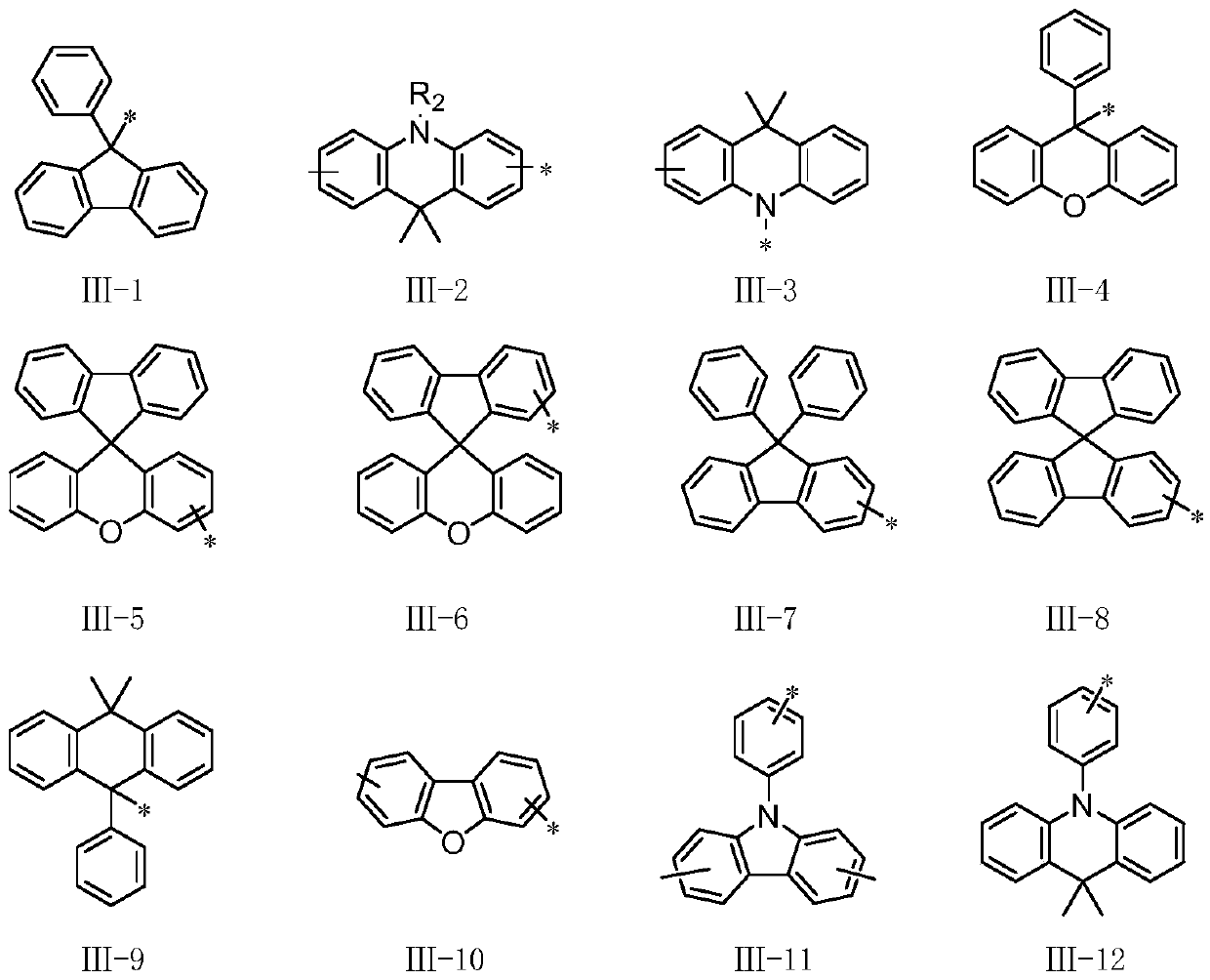

Luminescence auxiliary material, preparation method thereof and organic electroluminescent device

An auxiliary material, independent technology, applied in the fields of electro-solid devices, electrical components, organic chemistry, etc., can solve the problems of limited practical application, inability to withstand prolonged heating, and high evaporation temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0061] Its specific preparation method comprises the following steps:

[0062] 1) After adding reactant A-1 (50mmol) and reactant B-1 (55mmol) in toluene (300mL) into the reaction vessel, put it under nitrogen atmosphere, and add tris(dibenzylideneacetone) di Palladium (Pd 2 (dba) 3 , 0.5mmol), tri-tert-butylphosphine (P(t-Bu) 3 , 0.25mmol), sodium tert-butoxide (t-BuONa, 110mmol). After the addition, the reaction temperature was slowly raised to 110° C., and the mixture was stirred for 10 hours; then distilled water was added to the reaction solution and the reaction solution was extracted with ethyl acetate; the extracted organic layer was then dried using magnesium sulfate, and was dried using a rotary evaporation After removing the solvent, the remaining material was purified by column chromatography to obtain intermediate C-1 (30.9 g, yield 83%, MW: 743.65).

[0063] 2) After adding intermediate C-1 (40mmol) and reactant D-1 (44mmol) in toluene (300mL) in the reaction...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com