Method for preparing poly (lactic-co-glycolic acid)

A technology of polylactide and lactide, which is applied in the field of synthesis of medical absorbable copolymer polylactide, can solve the problem of expensive monitoring devices, no mention of copolymer thermal stability and molecular weight distribution, product heat Poor stability and other problems, to achieve the effect of broad copolymerization temperature and copolymerization time, highly controllable fine structure, and good processing thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

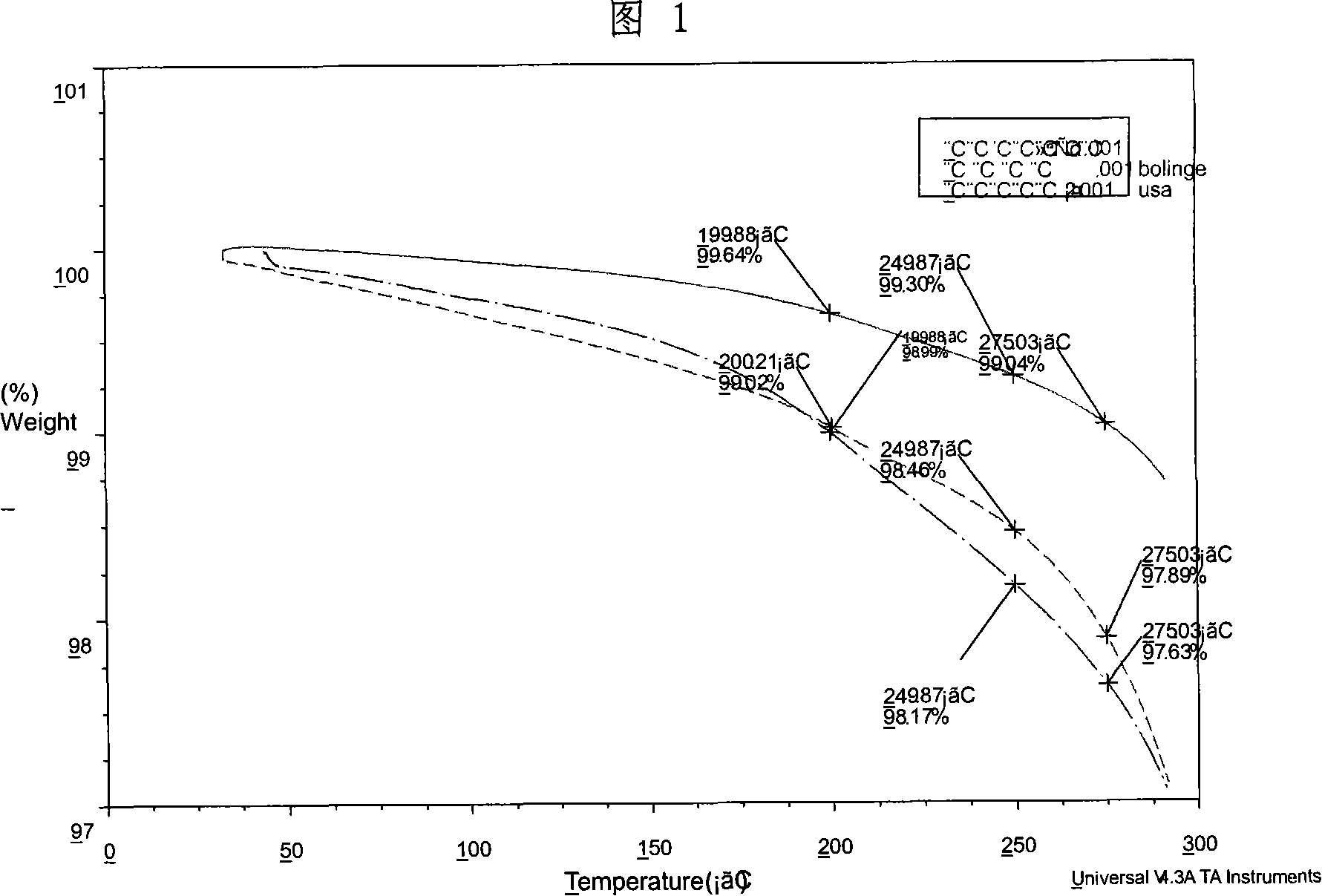

[0137] Embodiment 1: Preparation of 90 / 10 glycolide / L-lactide copolymer

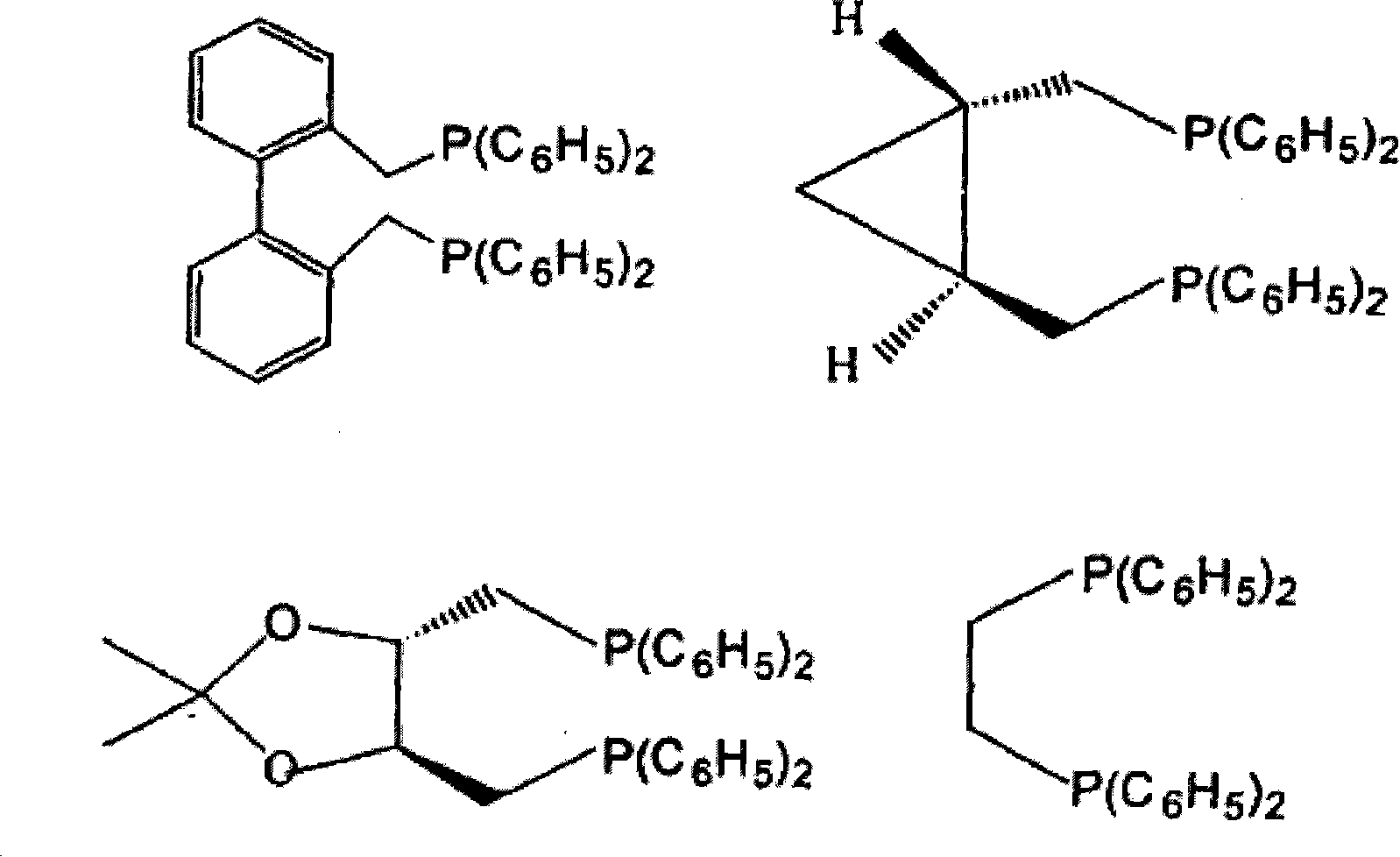

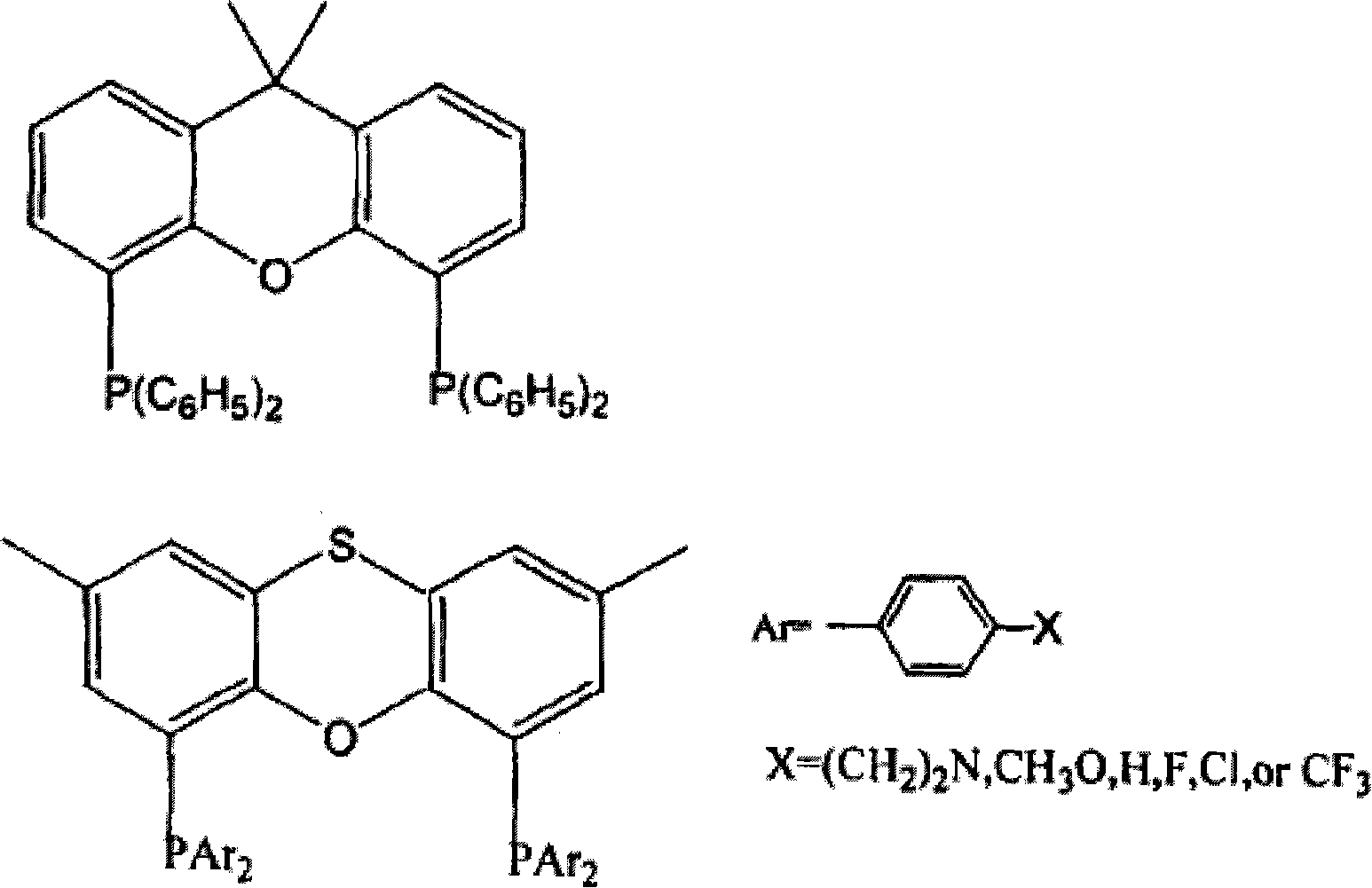

[0138] Catalyst preparation: The molar ratio of stannous octoate / benzyl alcohol / tri-p-hydroxyphenylphosphine is 1 / 15.0 / 1.5, with stannous octoate as the nominal name, toluene as the solvent, and a catalyst solution with a concentration of 0.012 mol / liter .

[0139] Accurately weigh 2088 grams of glycolide with a melting range of 82.0 to 82.5°C and 288 grams of L-lactide with a melting range of 95.5 to 96.1°C, add them to the reaction vessel, and then add 8.33ml of the prepared catalyst solution, that is, single The molar ratio of body / catalyst was 200,000.

[0140]At room temperature, absolute vacuum pressure ≤ 0.1mmHg, vacuumize for 24 hours to remove toluene solvent. Fill with high-purity nitrogen (99.999%) to keep the pressure at 0.035-0.050MPa. Raise the temperature to 98.0-105°C, stir for 1 hour, then raise the temperature to 205°C at a heating rate of 13-15°C / 10 minutes, and react for 15 hours. ...

Embodiment 2

[0158] Embodiment two: preparation 90 / 10 glycolide / L-lactide copolymer

[0159] Catalyst preparation: The molar ratio of triethylaluminum / dodecyl alcohol / 2,4,6-collidine is 1 / 10.0 / 2.5, with triethylaluminum as the nominal, toluene as the solvent, and the prepared concentration 0.0048 mol / L catalyst solution.

[0160] Accurately weigh 1044 grams of glycolide (melting range: 82.0-82.5°C) and 144 grams of L-lactide (melting range: 95.5-96.1°C) into the reaction vessel, then add 20.83ml of the prepared catalyst solution, The monomer / catalyst molar ratio was 100,000. At room temperature, absolute vacuum pressure ≤ 0.1mmHg, vacuumize for 24 hours to remove toluene solvent. Fill with high-purity nitrogen (99.999%) to keep the pressure at 0.035-0.050MPa. Raise the temperature to 98.0-105°C, stir for 1 hour, then raise the temperature to 185°C at 13-15°C / 10 minutes, and react for 12 hours. Stop the reaction, cool to room temperature, take out the material, crush it, and put the cru...

Embodiment 3

[0168] Embodiment three: prepare the copolymer of 15 / 85 glycolide / DL-lactide

[0169] Catalyst preparation: according to the molar ratio of lanthanum isopropoxide / benzyl alcohol / triisobutylphosphine as 1.0 / 15.0 / 1.0, with lanthanum isopropoxide as the nominal and toluene as the solvent, prepare a catalyst solution with a concentration of 0.01 mol / liter .

[0170] Accurately weigh 52.2 grams of glycolide (melting range: 82.0-82.5°C) and 367.2 grams of DL-lactide (melting range: 123.4-124.1°C) into the reaction vessel, then add 6.0ml of the prepared catalyst solution, The monomer / catalyst molar ratio was 50,000. At room temperature, absolute vacuum pressure ≤ 0.1mmHg, vacuumize for 24 hours to remove toluene solvent. Fill with high-purity nitrogen (99.999%) to keep the pressure at 0.035-0.050MPa. Raise the temperature to 128.0-135.0°C, stir for 1 hour, then raise the temperature to 165°C at 13-15°C / 10 minutes, and react for 15 hours. Stop the reaction, cool to room temperatur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com