Preparation method of curcumin rare earth complex, composite heat stabilizer for rigid PVC (polyvinyl chloride) and preparation method of composite heat stabilizer

A technology of composite thermal stabilizer and rare earth complexes, which is applied in the fields of compounds containing Group 3/13 elements of the periodic table, chemical instruments and methods, organic chemistry, etc. problems, to achieve the effects of excellent rheological properties and mechanical properties, excellent thermal stability during processing, and rich sources of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

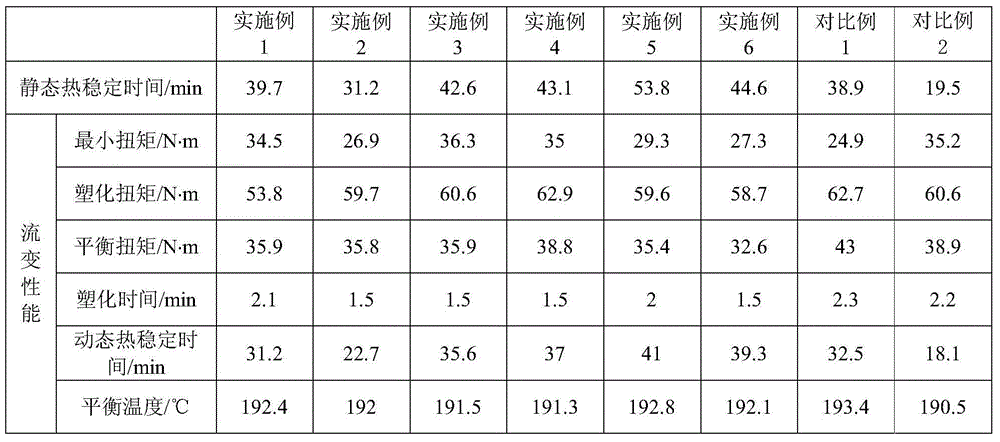

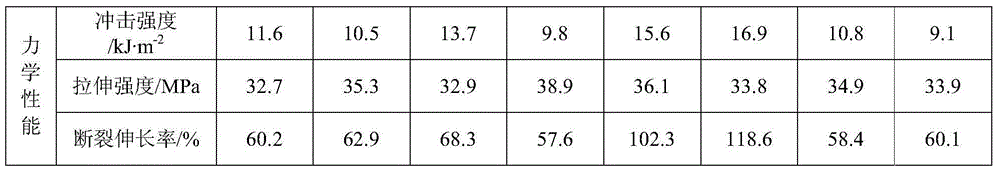

Examples

preparation example Construction

[0014] According to the preparation method of the curcumin rare earth complex of the first aspect of the present invention, comprise steps: (1) curcumin and dehydrated alcohol are added in the flask, heat and stir until curcumin dissolves completely; (2) drip in the flask Add rare earth nitrate solution, and then adjust the pH value of the solution to 6.0±0.2; (3) continue to stir and reflux, after the reaction is over, cool the reaction solution to room temperature, and filter with suction, then use the precipitate obtained by suction filtration Washing with absolute ethanol, suction filtration, and vacuum drying to obtain the curcumin rare earth complex.

[0015] In the preparation method of the curcumin rare earth complex according to the first aspect of the present invention, the curcumin rare earth complex is prepared under the condition of weak acidity and no weak base reagent, so its structure is stable.

[0016] In the preparation method of the curcumin rare earth comp...

Embodiment 1

[0030] 1. Preparation of Curcumin Rare Earth Complexes

[0031] Add 10g of curcumin and 80mL of absolute ethanol into a 250mL flask, stir in a water bath at 40°C until the curcumin is completely dissolved; then, add 100mL of rare earth lanthanum nitrate solution with a concentration of 0.1mol / L to the flask dropwise, and use phosphoric acid Salt buffer solution to adjust the pH of the solution to 6.0±0.2; then continue to stir and reflux for 2.5 to 4 hours. After the reaction is completed, cool the reaction solution to room temperature and filter with suction, and then wash the precipitate obtained by suction with absolute ethanol. After suction filtration and vacuum drying, curcumin lanthanum complex is obtained.

[0032] Among them, curcumin lanthanum complex, 1H NMR (300MHz, DMSO) δ (ppm): 3.84 (s, 6H, OCH 3 ), 6.06 (s, 1H, CH), 6.74-6.83 (d, 4H, =CH), 7.15-7.56 (m, 6H, Ar-H), 9.65 (s, 2H, Ar-OH). IR (KBr pellet, cm -1 )ν: 3071, 3016, 2972, 2944, 2848, 1628, 1603, 1510cm...

Embodiment 2

[0036] Prepare rigid PVC composite heat stabilizer according to the method of embodiment 1, except following differences:

[0037] 1. Preparation of Curcumin Rare Earth Complexes

[0038] Change rare earth lanthanum nitrate to rare earth neodymium nitrate, wherein, curcumin neodymium complex, 1 H NMR (300MHz, DMSO) δ (ppm): 3.84 (s, 6H, OCH 3 ), 6.06 (s, 1H, CH), 6.74-6.84 (d, 4H, =CH), 7.15-7.57 (m, 6H, Ar-H), 9.66 (s, 2H, Ar-OH). IR (KBr pellet, cm -1 )ν: 3071, 3015, 2971, 2944, 2843, 1628, 1602, 1510cm -1 .

[0039] 2. Preparation of composite heat stabilizer for rigid PVC

[0040] In parts by weight, 100 parts of curcumin neodymium complex, 10 parts of antioxidant 1010, 10 parts of glyceryl monostearate, and 15 parts of glyceryl tristearate were pre-mixed uniformly, then heated to 45°C and Stir and mix at high speed for 15 minutes at a spindle speed of 1100 rpm; then add 25 parts of calcium stearate and 10 parts of zinc stearate, raise the temperature to 75°C and mix a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com