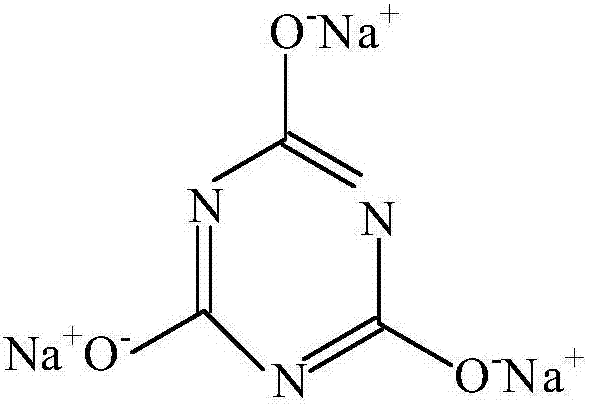

Application of trisodium cyanurate in improving the heat stability of PVC and composite heat stabilizer containing trisodium cyanurate

A composite heat stabilizer, trisodium cyanurate technology, applied in the field of trisodium cyanurate, can solve the problems of limitations, insignificant synergistic effect, and difficult availability of raw materials for the preparation of lanthanum cyanurate, so as to improve weather resistance and thermal stability properties, the effect of inhibiting zinc burning phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Prepare trisodium cyanurate as follows:

[0033] 1. Add 40g of cyanuric acid and 160g of water to the four-necked flask in turn, start stirring and heat up;

[0034] 2. Dissolve 37.2g of sodium hydroxide in 37g of water and stir with a glass rod until completely dissolved;

[0035] 3. When the temperature in the four-necked bottle rises to 55-60°C, pour the completely dissolved sodium hydroxide aqueous solution into the bottle in 3-4 times;

[0036]4. When the temperature is stabilized at 65-70°C, control the temperature and react for 2 hours. After the reaction is complete, stop heating. After the reaction slurry is cooled to below 48°C, filter the slurry under reduced pressure, dry and pulverize That is, trisodium cyanurate.

[0037] 5. The filtrate and washing liquid in the suction filtration process are recycled and used as reaction water for the preparation of the next batch of trisodium cyanurate.

[0038] Using the same method as above, replace sodium hydroxid...

Embodiment 2

[0049] In order to test the effect difference of the amount of trisodium cyanurate on the thermal stability of PVC, a composite heat stabilizer is prepared according to the formula in the following table 3, and the composite heat stabilizer weighs each raw material according to the amount in table 3, and then each raw material Mix well and serve.

[0050] table 3

[0051]

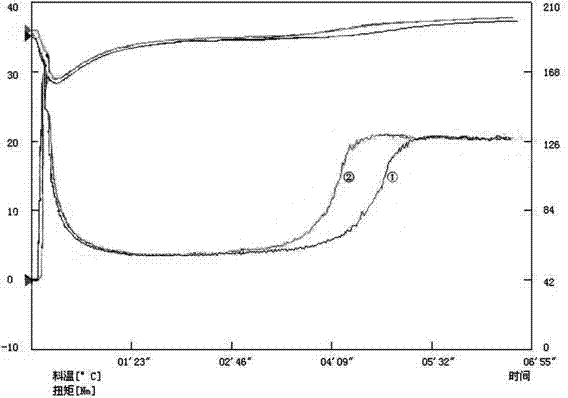

[0052] Mix the above-mentioned groups of composite heat stabilizers with 1000g of PVC resin respectively, mix the obtained mixture with a high-speed mixer at 110°C, press it with a double-roller machine at 185°C, cut into pieces after 7 minutes, and cut into pieces at 195°C Put it into a constant temperature aging box for testing, cut the pieces every 5 minutes, and observe the static color change of the cut pieces. At the same time, the mixed material is pressed into tablets with a rheometer, and the color of the extruded tablets is measured. The instrument used for color measurement is a colorimeter, ...

Embodiment 3

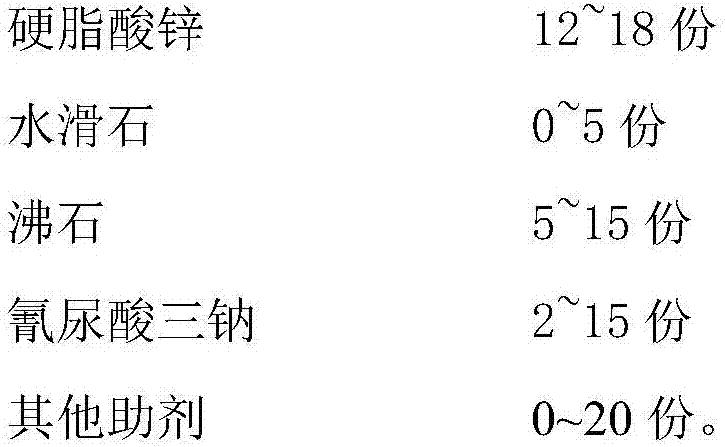

[0059] Accurately weigh zinc stearate, hydrotalcite, zeolite, trisodium cyanurate and other additives according to Table 5 below, wherein the other additives are a mixture of PE, β-diketone and calcium carbonate. Mix all components evenly to obtain a composite thermal stabilizer.

[0060] table 5

[0061]

[0062]

[0063] Take samples of each composite heat stabilizer and mix them with 1000g of PVC resin. The resulting mixture is mixed with a high-speed mixer at 110°C, pressed at 185°C with a double-roller machine, cut into pieces after 7 minutes, and cut into pieces at 195°C. Put it into a constant temperature aging box for testing, cut the pieces every 5 minutes, and observe the static color change of the cut pieces. At the same time, the mixed material is pressed into tablets with a rheometer, and the color of the extruded tablets is measured. The instrument used for color measurement is a colorimeter, which is represented by L, a, and b. The discoloration of each ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com