Lactic acid polyol esters and preparation method and application thereof in processing halogenated vinyl polymers

A polyol ester and vinyl halide technology, applied in the field of lactic acid polyol ester and its preparation, can solve the problems of poor compatibility of polyvinyl chloride, easy precipitation of pentaerythritol, high melting point, etc., and achieve good compatibility, low price, good The effect of applying the foreground

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

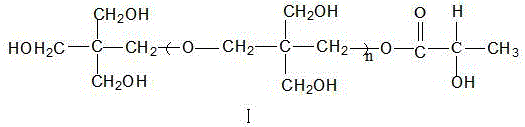

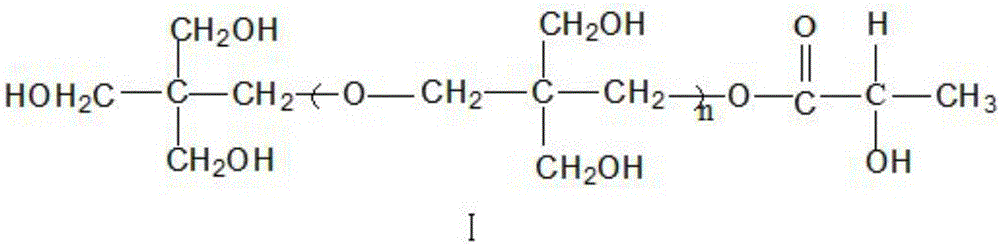

[0052] Monopentaerythritol and lactic acid were added to the four-necked flask according to the molar ratio of 1:1, and the temperature was controlled to react at 160 ° C until no water steam overflowed, then 0.75% of the lactic acid mass was added as a tetrabutyl titanate catalyst, and the reaction was continued until anhydrous. , and then pumped negative pressure for 30 minutes, poured out and cooled to obtain solid sample 1. The structural formula of sample 1 is shown in formula I, and n=0.

Embodiment 2

[0054]Monopentaerythritol and lactic acid were added to a four-necked flask according to a molar ratio of 1:1.2, and the reaction was performed at 180° C. under temperature control until no steam overflowed, and 0.5% of the mass of lactic acid was added as a tetrabutyl titanate catalyst, and the reaction was continued until anhydrous, The negative pressure was drawn for another 30 minutes, poured out for cooling, and solid sample 2 was obtained. The structural formula of sample 2 is shown in formula I, and n=0.

Embodiment 3

[0056] Monopentaerythritol and lactic acid were added to a four-necked flask according to a molar ratio of 1:1.5, and the temperature was controlled to react at 200 ° C until no water vapor overflowed, and a tetrabutyl titanate catalyst of 1% by mass of lactic acid was added, and the reaction was continued until anhydrous. , and then pumped negative pressure for 30 minutes, poured out and cooled to obtain solid sample 3. The structural formula of sample 3 is shown in formula I, and n=0.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com