Light rare-earth hydrotalcite-curcumin composite heat-stable assistant and preparation method thereof

A technology of heat stabilization assistant and light rare earth, which is applied in the field of polyvinyl chloride molding and processing, can solve the problems of high price of organotin heat stabilizers, toxic heat stabilizers of heavy metals, etc., and achieves simple formula composition and preparation process, and simple raw materials. Rich, wide-ranging effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

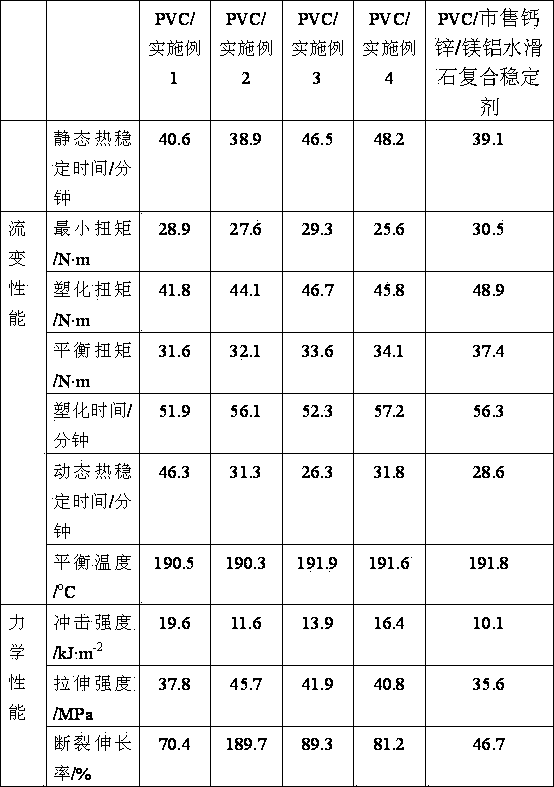

Examples

Embodiment 1

[0019] The lanthanum-magnesium hydrotalcite-curcumin composite thermal stability aid, calculated in parts by weight, includes 100 parts of lanthanum-magnesium hydrotalcite, 10 parts of curcumin, and 20 parts of calcium stearate.

[0020] Premix the lanthanum magnesium hydrotalcite and calcium stearate evenly at 100 o C Mechanical stirring and mixing for 3 hours, the speed of the mixer is 500±20 rpm to obtain the material pre-mixture. The material premix is cooled to 50 o After C, pre-mix with curcumin evenly, at 50 o C Mechanical stirring and mixing for 2 hours, the speed of the mixer is 300 rpm. The material is cooled to room temperature to obtain the lanthanum magnesium hydrotalcite-curcumin composite thermal stabilization aid.

Embodiment 2

[0022] Lanthanum-Nd-Mg-Mg hydrotalcite-curcumin composite thermal stability aid, according to parts by weight, take 60 parts of Lanthanum-Mg-Mg hydrotalcite, 45 parts of Nd-Mg hydrotalcite to form 105 parts of Lanthanum-Nd-Mg-Mg hydrotalcite, 90 parts of curcumin, stearin Calcium acid 40 parts.

[0023] 105 parts of lanthanum, neodymium and magnesium hydrotalcites are premixed with calcium stearate evenly, at 120 o C Mechanical stirring and mixing for 3 hours, the speed of the mixer is 700±20 rpm to obtain the material pre-mixture. Material premix material cooling to 60 o After C, pre-mix with curcumin evenly, at 60 o C Mechanical stirring and mixing for 2 hours, the speed of the mixer is 500 rpm. The material is cooled to room temperature to obtain the lanthanum neodymium magnesium hydrotalcite-curcumin composite thermal stabilization aid.

Embodiment 3

[0025] Neodymium-magnesium hydrotalcite / cerium-europium-magnesium hydrotalcite-curcumin composite thermal stability aid, in parts by weight, 40 parts of neodymium-magnesium hydrotalcite, 60 parts of cerium-europium-magnesium hydrotalcite, 90 parts of curcumin, 20 parts of calcium stearate share.

[0026] The neodymium magnesium hydrotalcite, cerium europium magnesium hydrotalcite and calcium stearate are pre-mixed evenly, at 110 o C Mechanical stirring and mixing for 3 hours, the speed of the mixer is 600±20 rpm to obtain the material pre-mixture. Material premix material cooling to 50 o After C, pre-mix with curcumin evenly, at 50 o C Mechanical stirring and mixing for 2 hours, the speed of the mixer is 400 rpm. The material is cooled to room temperature to obtain the neodymium magnesium hydrotalcite / cerium europium magnesium hydrotalcite-curcumin composite thermal stabilization aid.

PUM

| Property | Measurement | Unit |

|---|---|---|

| impact strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com