High heat-resistant redispersible powder cellulose nanocrystal and preparation method thereof

A technology of cellulose and nanocrystals, which is applied in the field of powder cellulose nanocrystals preparation, can solve the problems of poor heat resistance of cellulose nanocrystals, difficulty in redispersing in the water phase, and unsuitability for industrial production, so as to save the need for dialysis Handling, improved stability, easy-to-control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

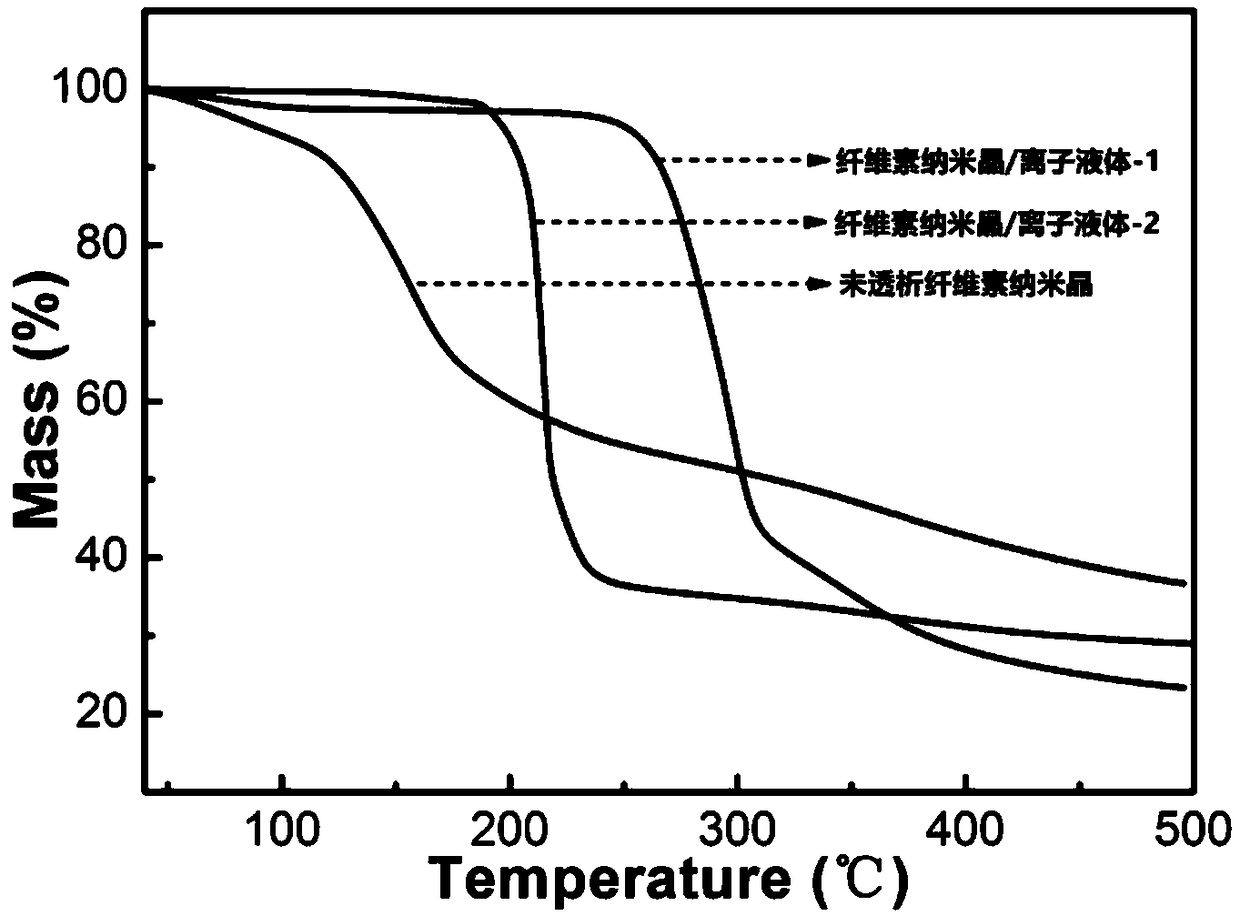

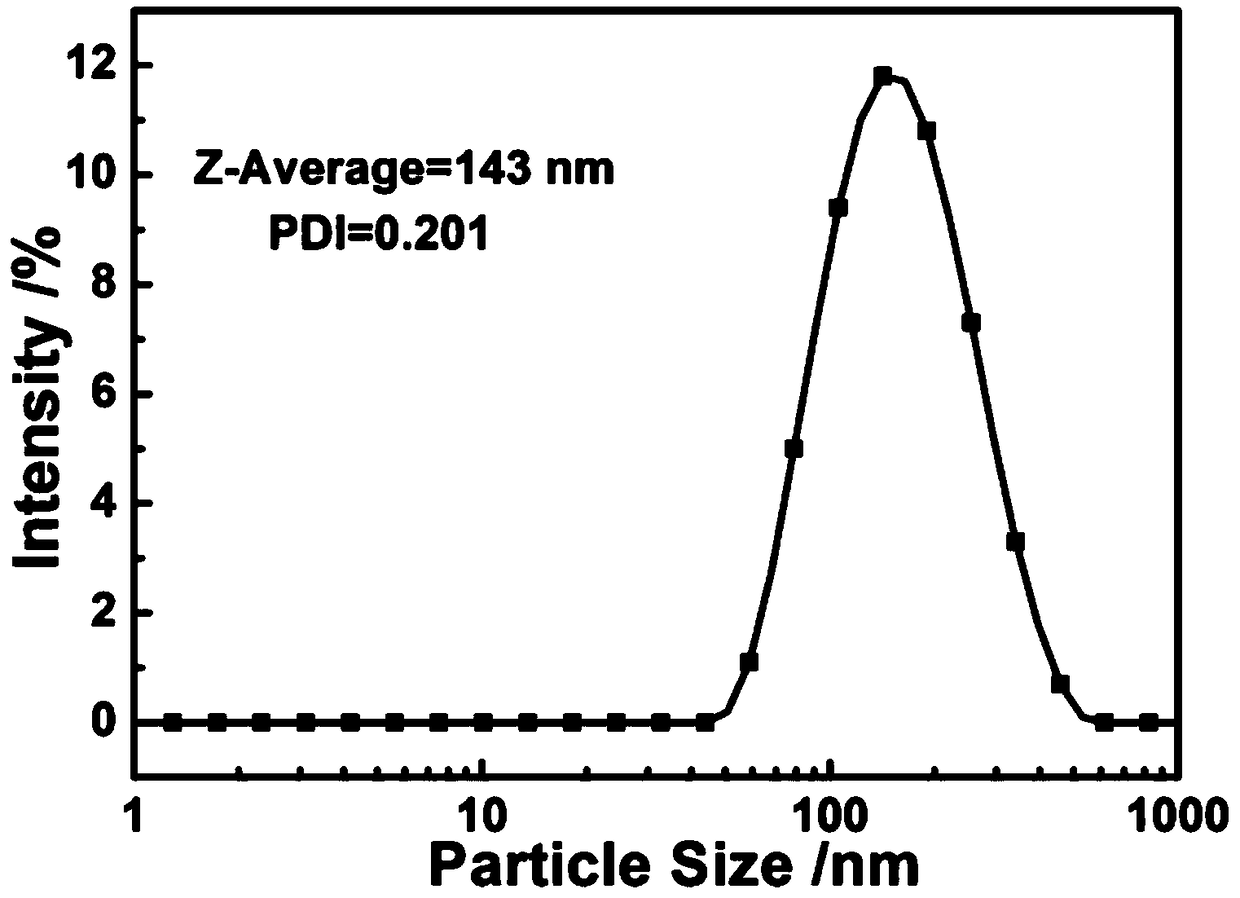

[0043] Add 5g pulp cellulose to 50ml, 55wt% H 2 SO 4After stirring at 50°C for 40 minutes, deionized water was added to terminate the reaction. The mixture was centrifuged at a speed of 10,000 rpm / min for 5 minutes in a high-speed centrifuge, and the supernatant was removed. The lower precipitate was washed with deionized water and then centrifuged again until the upper layer The liquid becomes cloudy. The obtained cellulose nanocrystal suspension was sonicated in an ice-water bath, and stored at 4°C for future use. Adjust the concentration of the prepared cellulose nanocrystal suspension to 1wt%, take 100g of the nanocrystal suspension and compound it with 0.33g of AmimCl type ionic liquid, heat the reaction solution in a water bath at 60°C for 3 hours, and spray dry the reaction solution to obtain a cellulose nanocrystal powder , the content of ionic liquid in the prepared powder cellulose nanocrystal is 24.8wt%. The heat resistance and redispersibility data are shown in ...

Embodiment 2

[0045] The type, amount and process flow of the raw materials used are the same as in Example 1, except that the concentration of the prepared cellulose nanocrystal suspension is adjusted to 1 wt%, and 100 g of the nanocrystal suspension is mixed with 0.1 g of AmimCl type ionic liquid. The ionic liquid content in the prepared powder cellulose nanocrystal is 9 wt%. The heat resistance and redispersibility data are shown in Table 1.

Embodiment 3

[0047] The types of raw materials used, the amount and the process flow are the same as in Example 1, except that the concentration of the prepared cellulose nanocrystal suspension is adjusted to 1 wt%, and 100 g of the nanocrystal suspension and 0.01 g of [OMIm] BF 4 Type ionic liquid composite, after heating in a water bath at 50° C. for 0.5 h, the reaction solution is spray-dried to obtain powdered cellulose nanocrystals, and the ionic liquid content in the prepared powdered cellulose nanocrystals is 1 wt%. The heat resistance and redispersibility data are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com