Starch and plant fiber composite biodegradable polyester film-blowing grade resin and preparation method

A technology for biodegrading polyester and plant fibers, applied in the field of blown film resins, can solve the problems of high cost, poor compatibility, and incomplete degradation, and achieve the advantages of improving heat resistance and strength, improving comprehensive performance, and improving aging performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

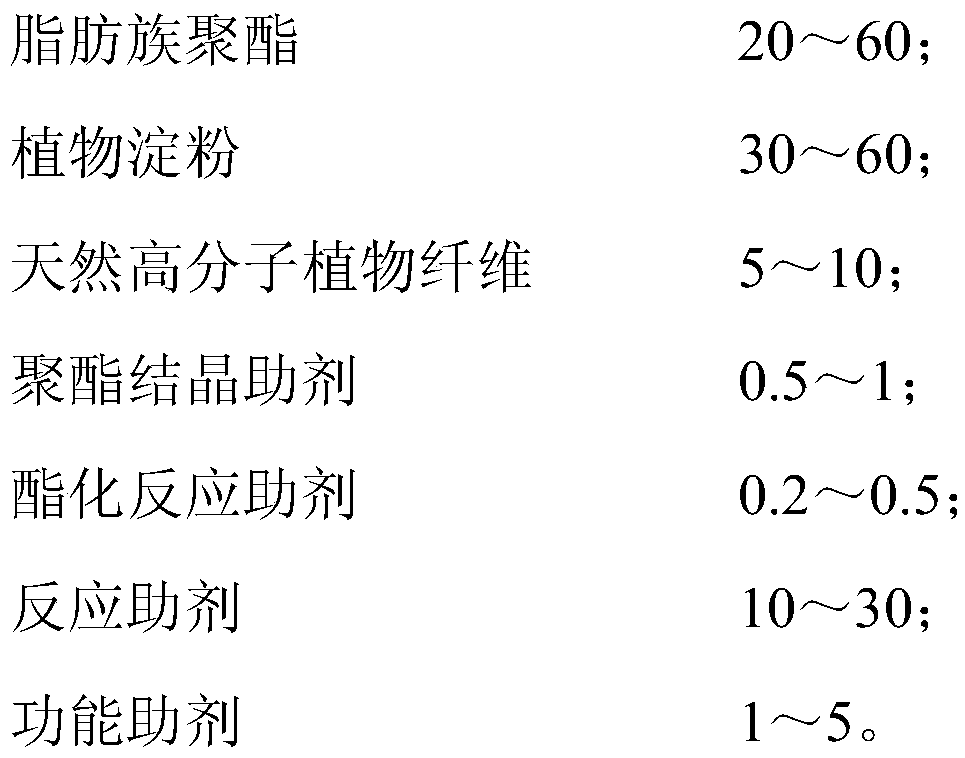

[0048] A kind of starch / plant fiber composite biodegradable polyester blown film grade resin provided in this embodiment comprises the following components in parts by weight:

[0049]

[0050] Wherein, the polyester polymer is a mixture of poly(butylene adipate / terephthalate) and polylactic acid, and the mass ratio of the two is 8:2, the melting of poly(butylene adipate / terephthalate) The index is between 3.0 and 3.5, and the heat sealing strength is not less than 15N / m 2 . The molecular weight of polylactic acid is more than 10,000, and the melt index is between 10 and 30.

[0051] The amylose content of tapioca starch is above 20%, its moisture content is less than or equal to 10%, and its whiteness is greater than or equal to 87°.

[0052] The straw fiber is soaked in a sodium hydroxide solution with a mass concentration of 5%, wherein the mass ratio of the straw fiber to the sodium hydroxide solution is 1:20, and the mesh number of the straw fiber is 40 mesh;

[005...

Embodiment 2

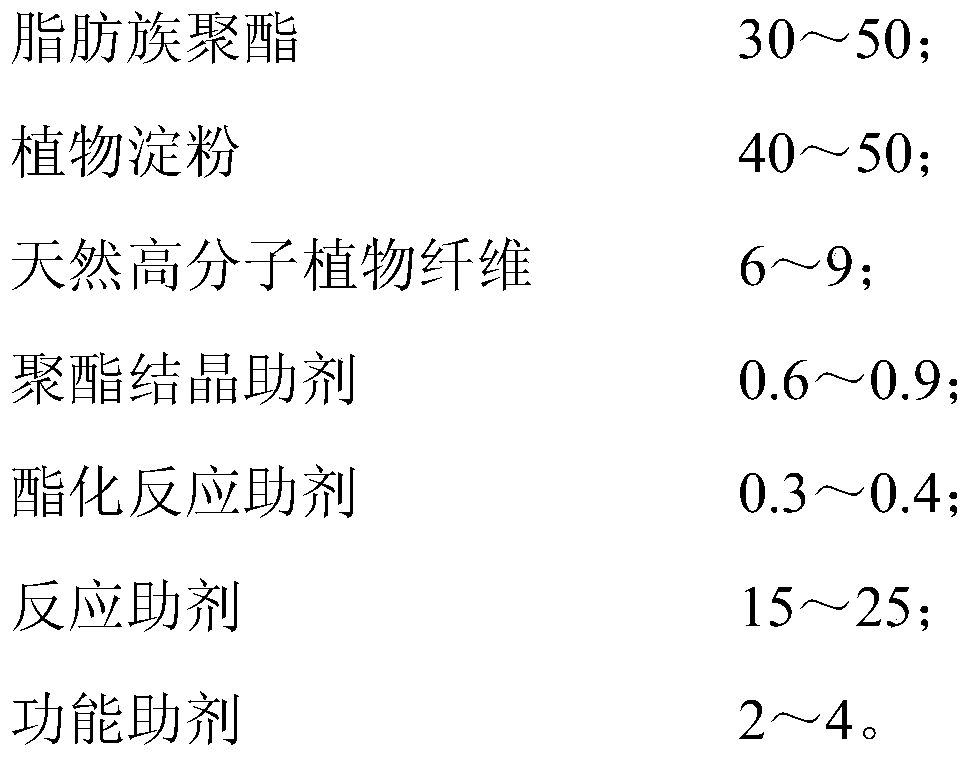

[0063] A kind of starch / plant fiber composite biodegradable polyester blown film grade resin provided in this embodiment comprises the following components in parts by weight:

[0064]

[0065]

[0066] Wherein, the polyester polymer is a mixture of poly(butylene adipate / terephthalate) and polylactic acid, and the mass ratio of the two is 7:3, the melting of poly(butylene adipate / terephthalate) The index is between 3.0 and 3.5, and the heat sealing strength is not less than 15N / m 2 . The molecular weight of polylactic acid is more than 10,000, and the melt index is between 10 and 30.

[0067] The amylose content of potato starch is above 20%, its moisture content is less than or equal to 10%, and its whiteness is greater than or equal to 87°.

[0068] The wheat straw fibers are soaked in a sodium hydroxide solution with a mass concentration of 4%, wherein the mass ratio of the wheat straw fibers to the sodium hydroxide solution is 1:18, and the mesh number of the wheat...

Embodiment 3

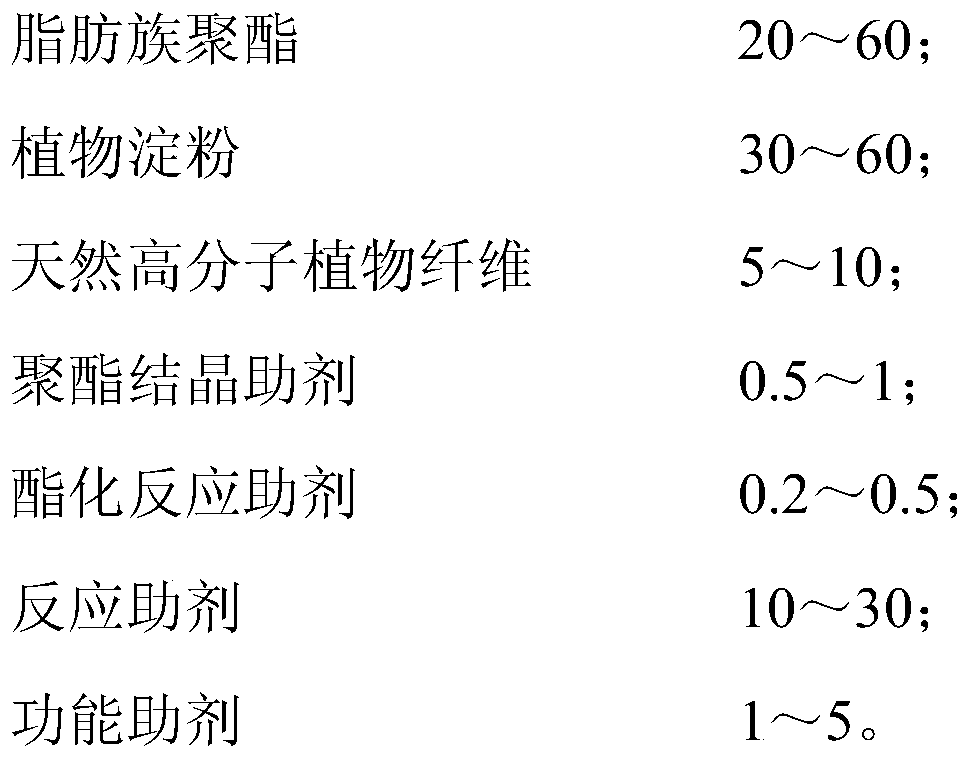

[0079] A kind of starch / plant fiber composite biodegradable polyester blown film grade resin provided in this embodiment comprises the following components in parts by weight:

[0080]

[0081] Wherein, the polyester polymer is a mixture of polybutylene adipate / terephthalate and polylactic acid, and the mass ratio of the two is 9:1. The melt index of poly(butylene adipate / terephthalate) is between 3.0 and 3.5, and the heat seal strength is not less than 15N / m2 . The molecular weight of polylactic acid is more than 10,000, and the melt index is between 10 and 30.

[0082] The amylose content of corn starch is above 20%, its moisture content is less than or equal to 10%, and its whiteness is greater than or equal to 87°.

[0083] The sisal fiber is soaked in a sodium hydroxide solution with a mass concentration of 7%, wherein the mass ratio of the sisal fiber to the sodium hydroxide solution is 1:18, and the mesh number of the sisal fiber is 80 mesh;

[0084] In the treated...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com