Polyvinylidene chloride composition capable of prolonging food shelf life

A polyvinylidene chloride, food preservation technology, applied in the field of polyvinylidene chloride resin, can solve the problems of lack of reproducibility, lack of uniformity of the composition, etc., achieve good transparency, improve processing thermal stability, and product performance excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

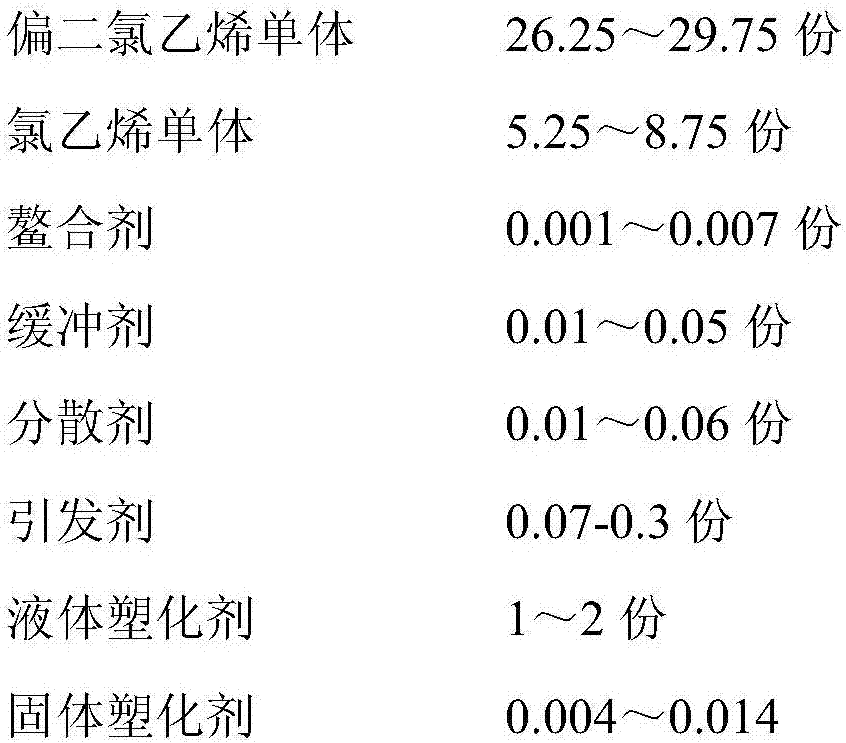

[0027] A kind of polyvinylidene chloride composition that prolongs food preservation period, its raw material formula is as follows:

[0028]

[0029] The preparation steps are as follows:

[0030] (1) Put 55kg of deionized water, 4g of disodium edetate, 22g of methylcellulose, 22g of Hydroxypropyl methylcellulose, 25g sodium pyrophosphate, 105g diisopropyl peroxydicarbonate, 28kg vinylidene chloride, and 7kg vinyl chloride were cold dispersed for 30 minutes, then heated up to 37°C at a stirring speed of 22.5rpm to start polymerization ;

[0031] (2) Gradually increase the temperature to 55.5°C at a temperature rate of 1.5°C / h, and simultaneously increase the stirring speed to 30rpm at a stirring speed of 1.3rpm / h;

[0032] (3) Terminate polymerization after reacting for 36 hours, discharge, heat up, remove residual monomers in a vacuum, then add 1.75 kg of tributyl citrate (TBC), then centrifuge and dry;

[0033] (4) Add 7 g of dialkyl thiodipropionate intermittently to...

Embodiment 2

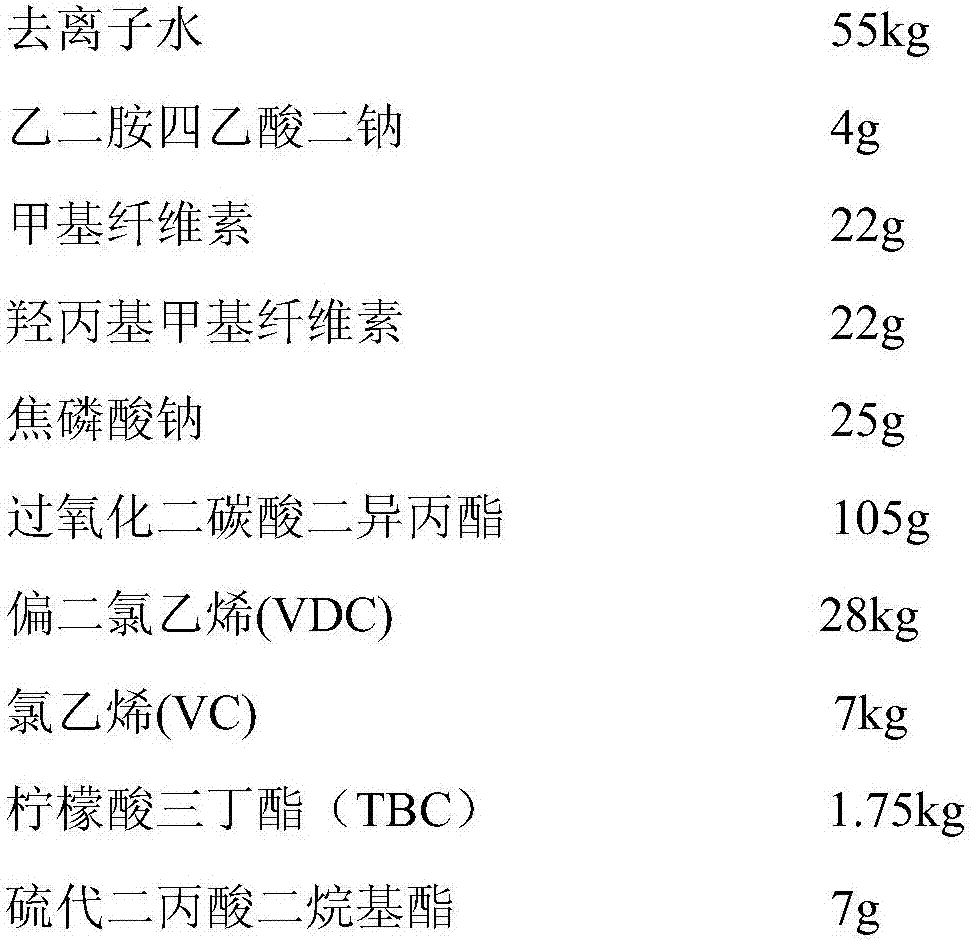

[0035] A kind of polyvinylidene chloride composition that prolongs food preservation period, its raw material formula is as follows:

[0036]

[0037] The preparation method is the same as in Example 1, and the result: a white powdery composition is obtained.

Embodiment 3

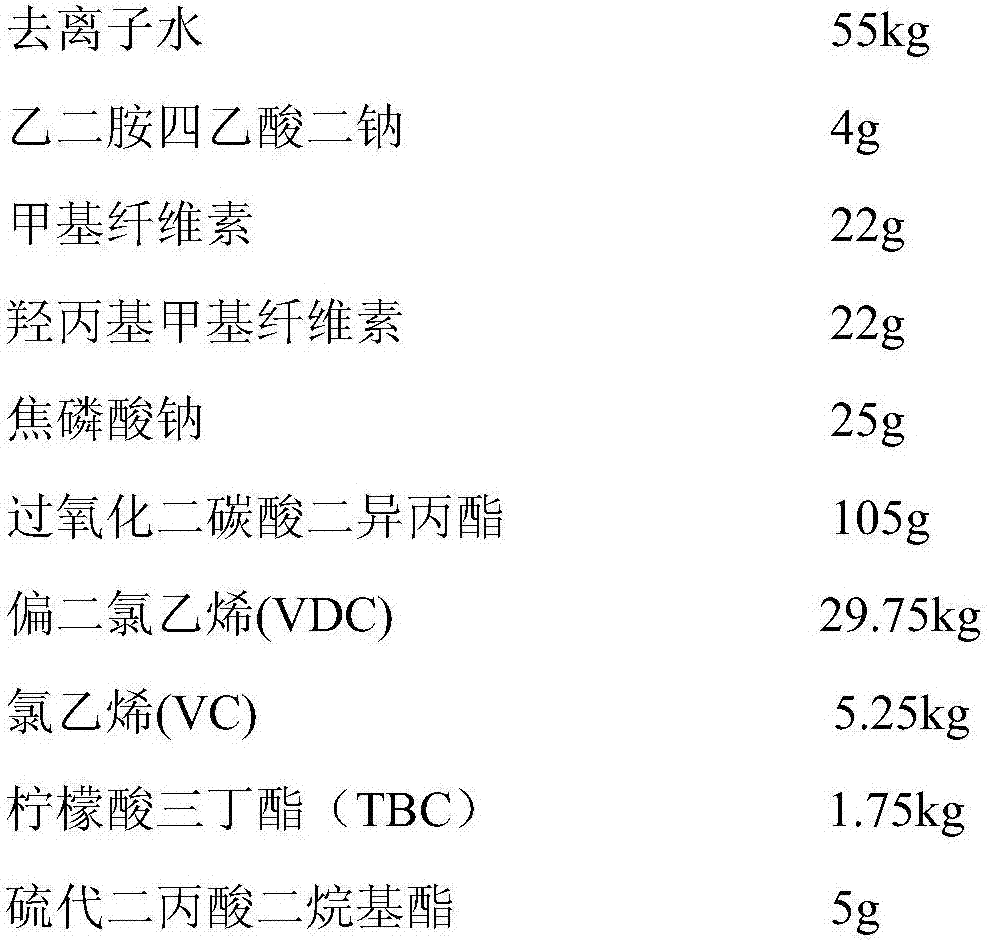

[0039] A kind of polyvinylidene chloride composition that prolongs food preservation period, its raw material formula is as follows:

[0040]

[0041]

[0042] The preparation method is the same as in Example 1, and the result: a white powdery composition is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

| haze | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com