Biodegradable material containing aliphatic polycarbonate, and preparation method and application thereof

A biodegradable material, aliphatic polyester technology, applied in the application field of preparing biodegradable films, can solve the problems of low glass transition temperature and melt strength, low film tear strength, low processing temperature, etc. Thermal and process stability properties, ease of large-scale industrial production, high toughness and tear strength effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

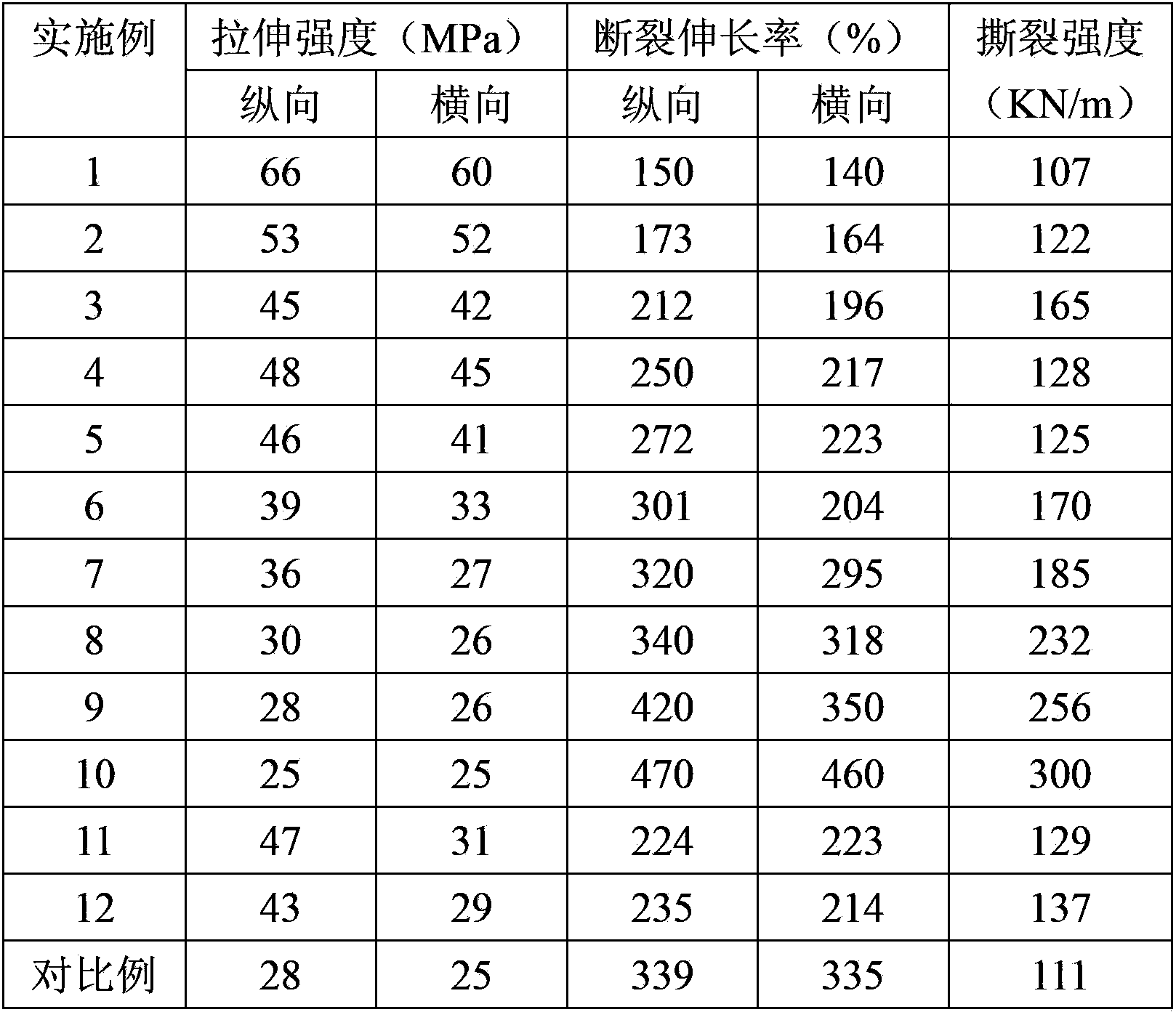

Examples

Embodiment 1

[0039] Based on the parts by weight of polybutylene carbonate after drying. 18 parts by weight of polybutylene carbonate after drying, 72 parts by weight of polylactic acid (Natureworks 2002D), 10 parts by weight of ethylene-methacrylic acid sodium salt copolymer (DuPont Surlyn 1605), polyethylene glycol (PEG-400) 2 parts by weight, 0.3 parts by weight of erucamide, 0.3 parts by weight of stearic acid and 0.1 part by weight of sorbitol were premixed in a high-speed mixer for 30 minutes; after mixing well, 0.01 parts by weight of dicumyl peroxide (DCP) was added part, 0.1 part by weight of triallyl isocyanurate and continue mixing for 5 minutes to obtain a mixed material; the mixed material is added to a twin-screw extruder with a length-to-diameter ratio of 40:1, and the temperature is Melt blending at 150-190°C, air-cooled, stretched into strips, and pelletized; vacuum-dried and dewatered the obtained granular mixed resin slices to obtain biodegradable materials containing al...

Embodiment 2

[0042] Based on the parts by weight of polybutylene carbonate after drying. After drying, 17 parts by weight of polybutylene carbonate (PBC), 8.5 parts by weight of polyhexamethylene carbonate (PHC), 59.5 parts by weight of polylactic acid (Natureworks 4032D), ethylene-methyl methacrylate copolymer (Sumitomo WH303 ) 15 parts by weight, 1 part by weight of polyethylene glycol (PEG-1000), 0.3 parts by weight of erucamide, 0.3 parts by weight of calcium stearate and 0.1 parts by weight of silicon dioxide, premixed in a high-speed mixer for 30 minutes; After fully mixing evenly, add 0.1 parts by weight of dicumyl peroxide (DCP) and 0.05 parts by weight of triallyl isocyanurate and continue mixing for 5 minutes to obtain a mixed material; add the mixed material In a twin-screw extruder with a length-to-diameter ratio of 40:1, melt blending is carried out at a temperature of 150-190°C, stretched into strips by air cooling, and pelletized; the obtained granular mixed resin slices are...

Embodiment 3

[0045] Based on the parts by weight of the dried polypentamethylene carbonate. After drying, 38 parts by weight of polypentamethylene carbonate (PPMC), 57 parts by weight of polylactic acid (Natureworks 4032D), 5 parts by weight of ethylene-methacrylic acid sodium salt copolymer (DuPont Surlyn 1605), polyethylene glycol (PEG -1000) 1 part by weight, 0.3 part by weight of erucamide, 0.3 part by weight of stearic acid and 0.1 part by weight of silicon dioxide, pre-mixed in a high-speed mixer for 30 minutes; after fully mixing, add diisopropyl peroxide 0.1 parts by weight of benzene (DCP) and 0.3 parts by weight of triallyl isocyanurate were mixed for 5 minutes to obtain a mixed material; the mixed material was added to a twin-screw extruder with an aspect ratio of 40:1 In the machine, melt blending is carried out at a temperature of 150-190 ° C, and air-cooled stretching is used to form strips and pelletized; the obtained granular mixed resin chips are vacuum-dried to remove wat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com