Autoignition compositions

a technology of auto-ignition composition and composition, which is applied in the direction of explosive compositions, inorganic oxygen-halogen salt explosive compositions, weapons, etc., can solve the problems of violent combustion reaction rather than controlled combustion reaction, and the composition is not necessarily suitable for auto-ignition, so as to achieve the effect of reducing melting and increasing the available combustion surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

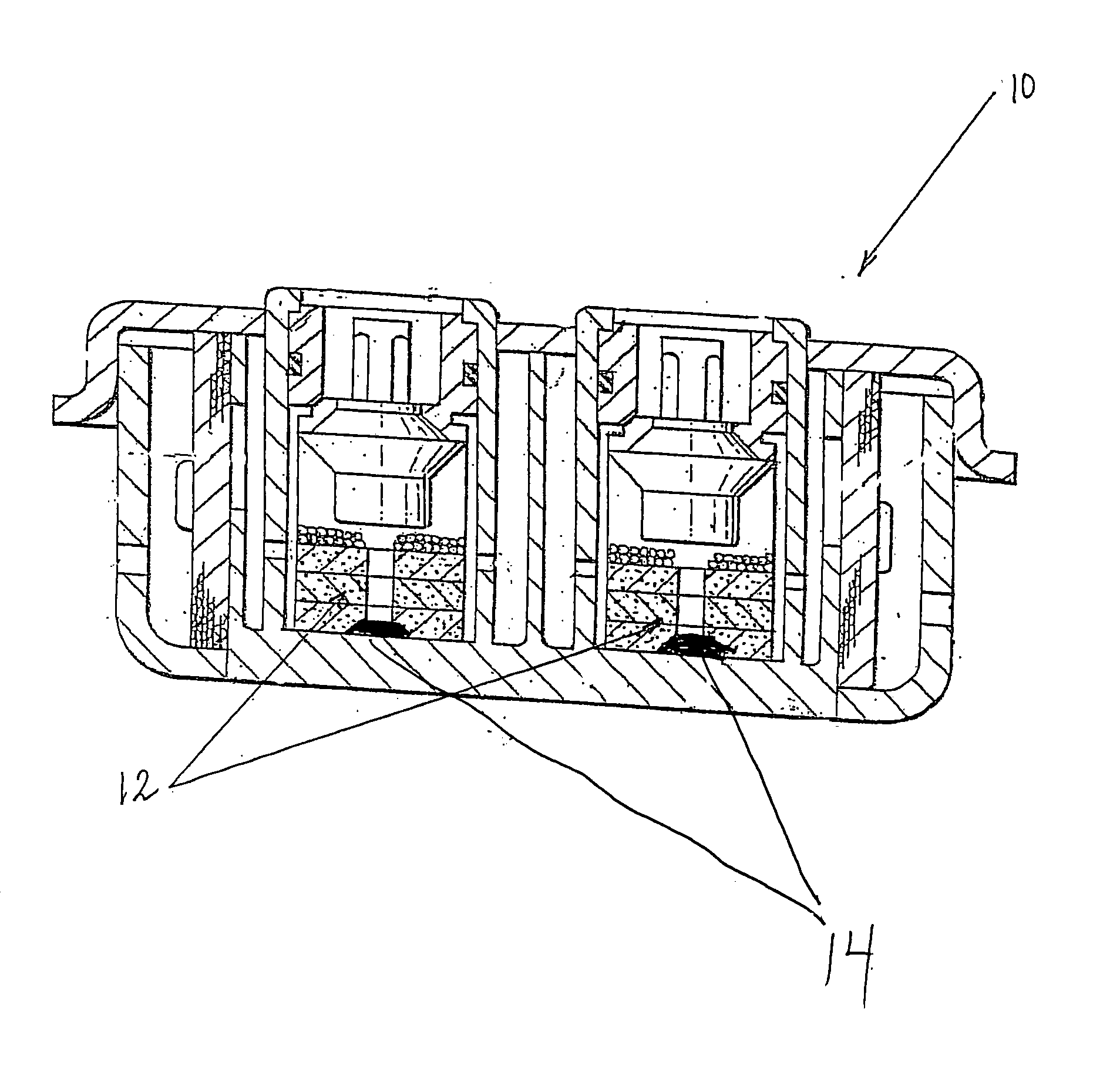

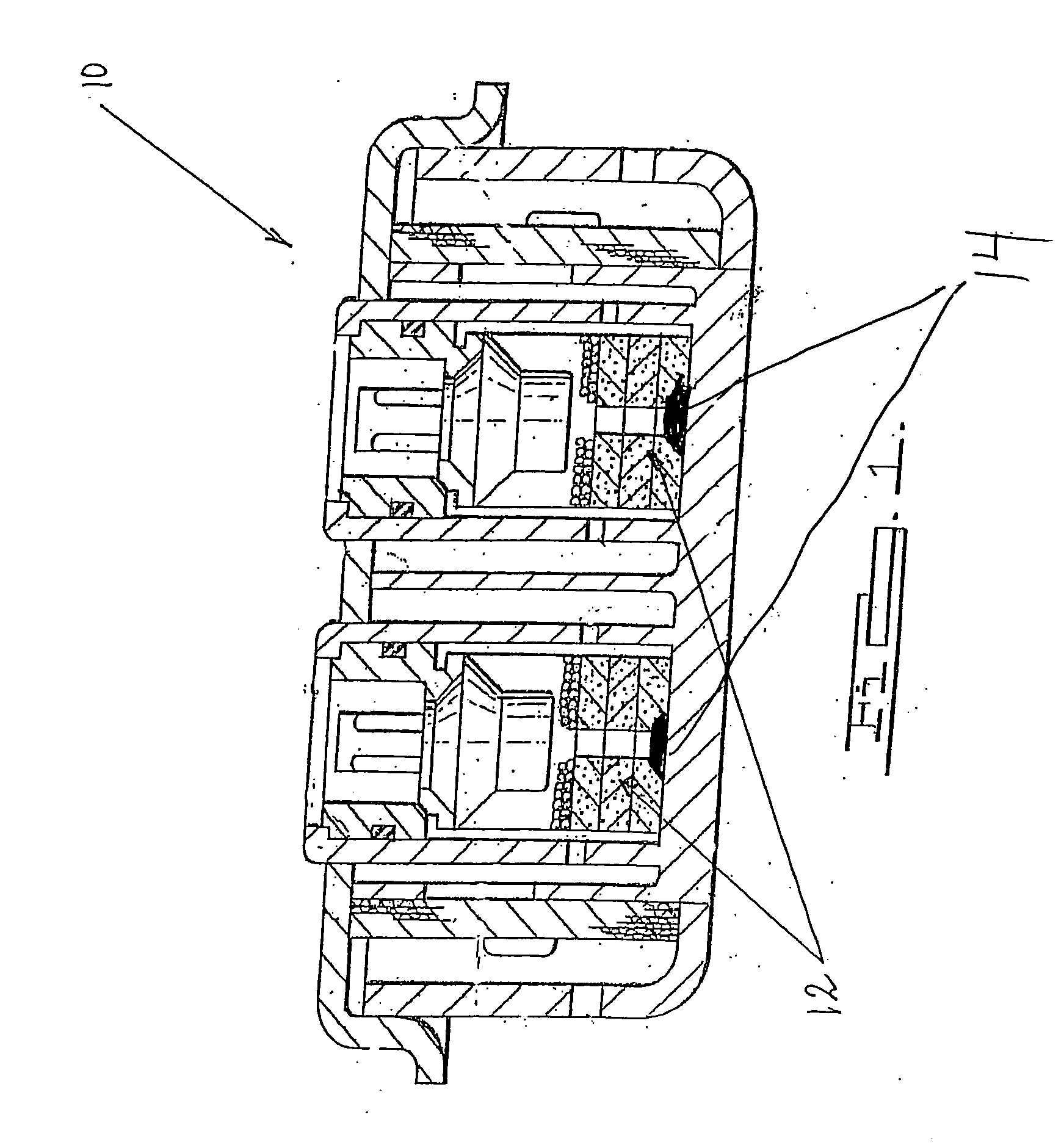

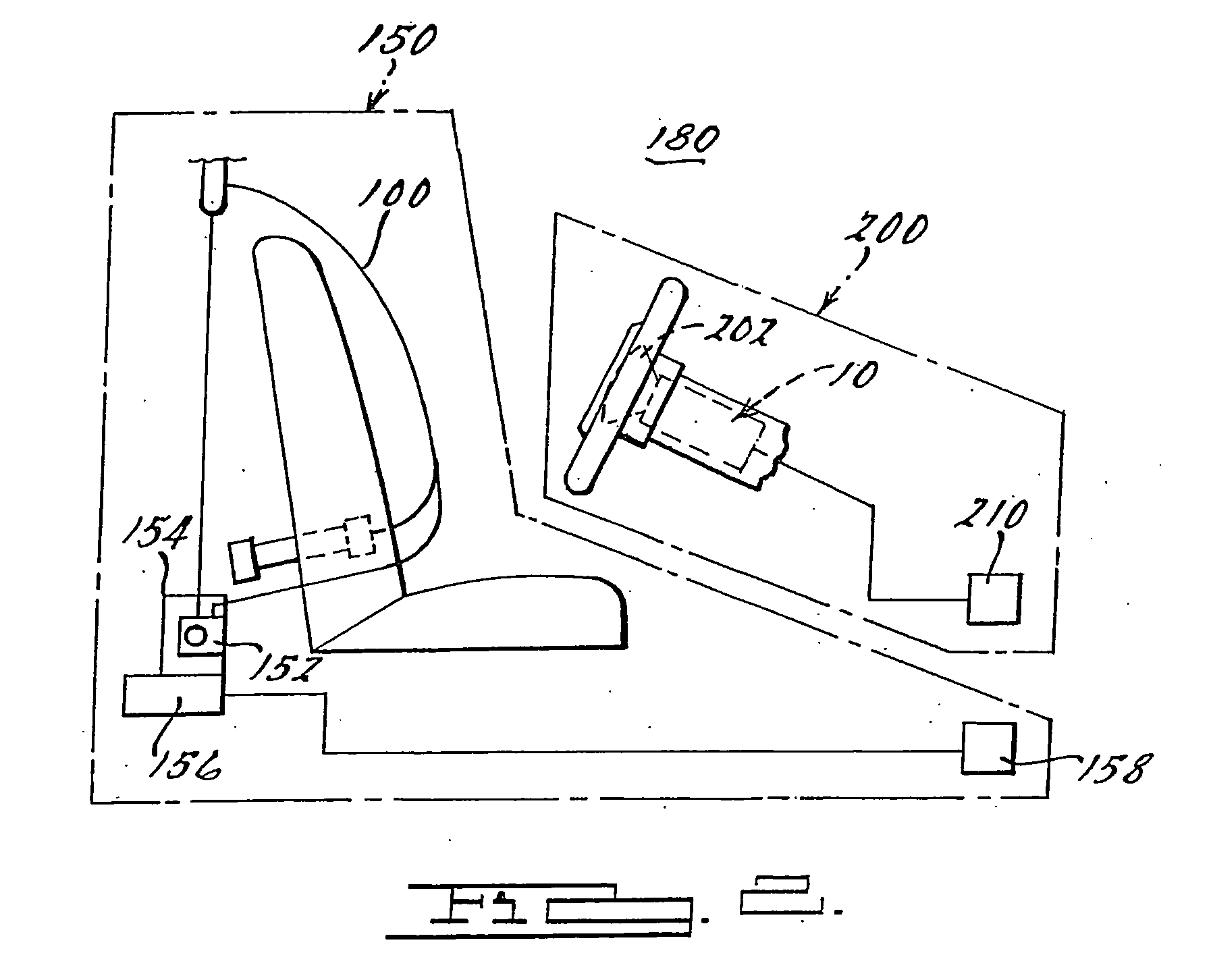

Image

Examples

examples

[0010]

LiteratureAmountBaselinePost-AgingExampleNameMP ( C.)with KCAutoignitionAutoignition1L-Tartaric Acid168-17043%154IgnitedDuring Aging2D-Tartaric Acid168-17043%154IgnitedDuring Aging3DL-Tartaric Acid20643%1851884Meso-Tartaric Acid14043%146IgnitedDuring Aging5L-Tartaric Acid,>250 48%>250>250 Mono-K Salt6DL-Malic Acid131-13335%>250>250 7Succinic Acid188-19030%2102108Diglycolic Acid142-14536%1552139Malonic Acid135-13739%>250>250 10Trans-Glutaconic137-13926%188211Acid11D-Glutamic Acid200-20226%23523012Adipic Acid152-15422%23724813Mucic Acid21537%223221142,2-Bis(hydroxymethyl)189-19123%>250>250 propionic acid15Citric Acid152-15436%>250>250 16Phenylmalonic Acid15320%>250>250 17D-Quinic Acid16825%>250>250

examples 1-17

[0011] Stoichiometric mixtures of each of the acids with potassium chlorate (KC) were made by grinding the raw materials separately in a vibratory grinder, and then blending by hand in a mortar and pestle. The autoignition test consisted of an aluminum fixture placed on a laboratory hot plate. The fixture was machined to accommodate a 0.3-0.5 g sample of autoignition material and a thermocouple probe. The tip of the probe was positioned directly below the autoignition composition, between the sample and the hotplate surface. The thermocouple was connected to a digital readout display and the hot plate was turned on to a heating rate of 30-50° C. per minute. The autoignition temperature was recorded as the temperature at which the sample combusted vigorously. Each sample was tested for thermal stability by placing about 15 g in a sealed glass vial and placing in a chamber at 107° C. for 400 hours. The hot plate autoignition was tested again after aging was complete.

examples 18-19

[0012] Compositions were made containing DL-tartaric acid and KC in different ratios. This illustrates that the autoignition temperature does not substantially change if the composition is fuel-rich or oxidizer-rich.

Auto-DL-TartaricKCOxygen BalanceignitionExampleAcid (wt. %)(wt. %)(wt. % O2)(C.)183070+11.4184195545−11.7183 3 (for comparison)4357-0-185

[0013] For comparison purposes, some of the compositions were tested on a TGA (thermogravimetric analyzer) with a smaller sample size and at a slower heating of 10° per minute. The results are as follows. This illustrates that the relative autoignition temperature does not substantially change with the sample size and heating rate.

Composition FromHot Plate AI (0.3-0.5TGA AI (20-50Exampleg at 30-50 C. / min)mg at 10 C. / min)11541423185171132232001123521312237222

[0014] Is should be noted that the stereochemistry of the carboxylic acids described herein is relevant to this invention. For example, Tartaric Acid has three stereoisomers as f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| weight percent | aaaaa | aaaaa |

| weight percent | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com