Supercritical fluid continuous extrusion high-performance recyclable PA foam material and preparation method thereof

A supercritical fluid and foaming material technology, which is applied in the field of foam material preparation, can solve the problems of low molding efficiency, high technical difficulty, and impossibility of continuous production, and achieve high mechanical properties and controllable foaming ratio , Improve the effect of temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

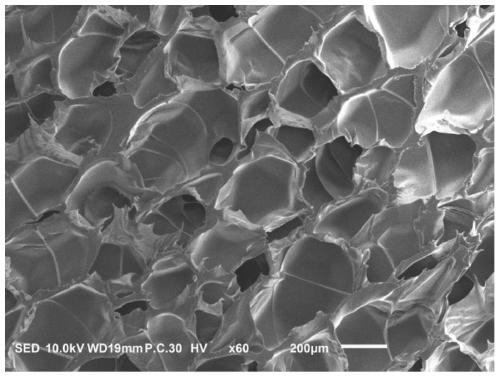

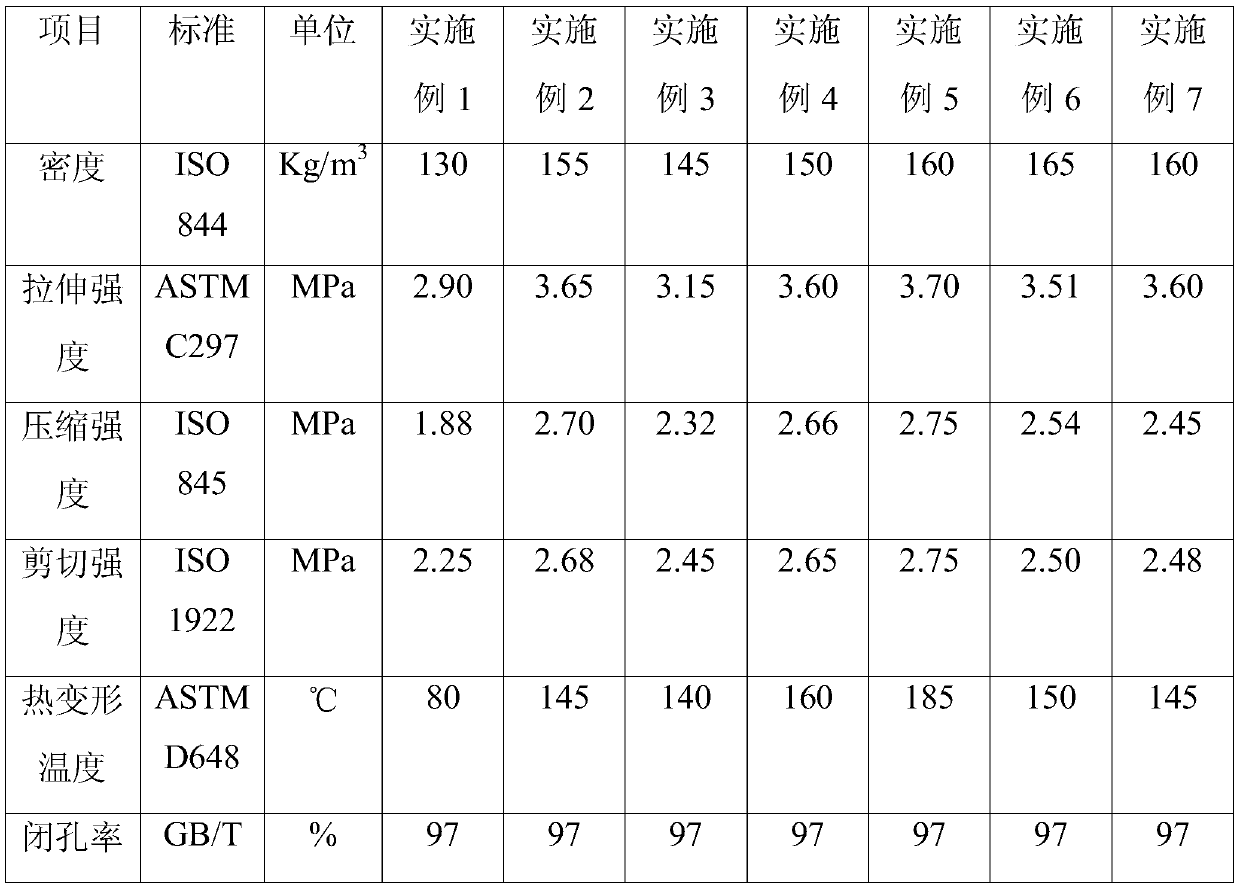

[0038] Weigh 98 parts of PA6 resin (Hangzhou Polymershun, J2400), 0.5 part of ADR 4468 (multifunctional epoxy compound, BASF), 0.5 part of long carbon chain carboxylate nucleating agent (Bruggemann, P22), 1 part Glass fiber (Hangzhou Gaoke, ECP) is added to the double-stage extrusion foaming equipment, supercritical CO 2 The injection rate is 1.45kg / h; the ZE40 twin-screw extrusion temperature is: 60°C, 120°C, 180°C, 220°C, 230°C, 230°C, 230°C, 230°C, and the screw speed is set at 80rpm. KE90 single screw temperature is 200°C, 200°C, 200°C, 200°C, 200°C, 200°C, the speed is set at 6rpm, and the density is 130Kg / m 3 PA6 foam sheet with uniform and dense cells.

Embodiment 2

[0040] Weigh 69 parts of PA6 resin (Hangzhou Jushun, J2400), 0.5 part of chain extender ADR 4468 (multifunctional epoxy compound, BASF), 0.5 part of MgO (Hangzhou Zhiti, 20um) into the two-stage extrusion foaming equipment, 30 parts of glass fiber (Hangzhou Gaoke, ECP) were added to the system from the side feed, supercritical CO 2 / Cyclopentane mixed gas injection rate 1.5kg / h; ZE40 twin-screw extrusion temperature: 60°C, 120°C, 180°C, 220°C, 230°C, 230°C, 230°C, 230°C, screw speed setting 80rpm . KE90 single screw temperature is 200°C, 200°C, 200°C, 200°C, 200°C, 200°C, the speed is set at 6rpm, and the density is 155Kg / m 3 Fiber-reinforced PA foam sheet with uniform and dense cells.

Embodiment 3

[0042] Weigh 80 parts of PA6 resin (Hangzhou Jushun, J2400), 7 parts of recycled PA6 foam material, 2 parts of PMDA (Wuhan co-created) and ADR 4468 (BASF) mixture, 1 part of SiO 2 (Hangzhou Zhiti, 20um), add two-stage extrusion foaming equipment, 10 parts of glass fiber (Hangzhou Hi-Tech, ECP) are added to the system from the side feed, supercritical CO 2 / Cyclopentane mixed gas injection rate 1.5kg / h; ZE40 twin-screw extrusion temperature: 60°C, 120°C, 180°C, 220°C, 230°C, 230°C, 230°C, 230°C, screw speed setting 80rpm . KE90 single screw temperature is 200°C, 200°C, 200°C, 200°C, 200°C, 200°C, the speed is set at 6rpm, and the density is 160Kg / m 3 Fiber-reinforced PA foam sheet with uniform and dense cells.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com