Lithium ion battery and preparation method thereof

A lithium-ion battery and current collector technology, applied in the manufacture of electrolyte batteries, secondary batteries, battery electrodes, etc., can solve the problems of active lithium ion loss, consumption of active lithium ions, lithium battery capacity decay, etc., and achieve Li ion concentration distribution Uniformity, improve battery consistency, improve the effect of charging and discharging efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

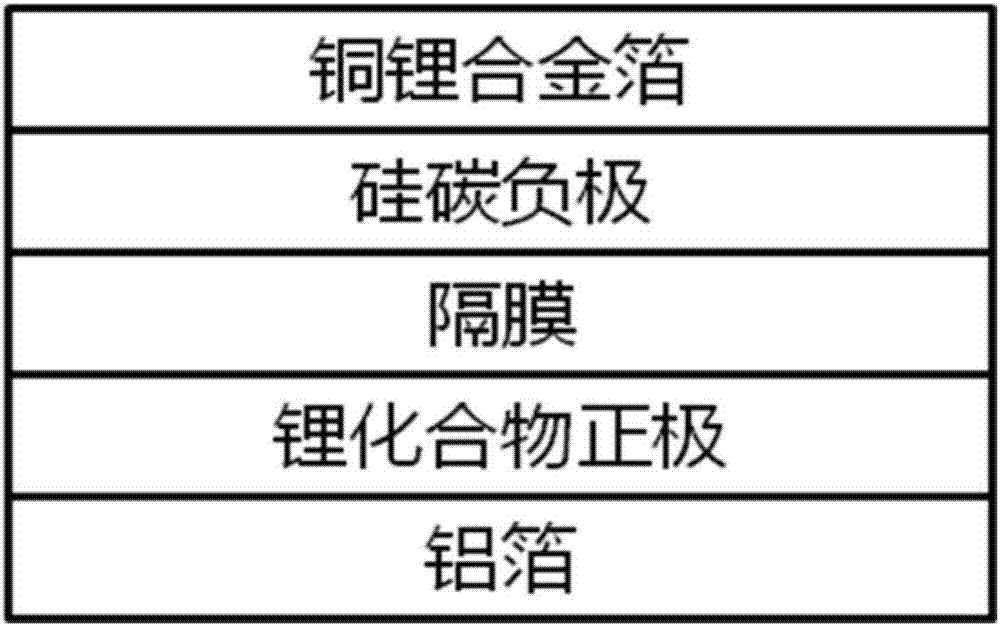

Image

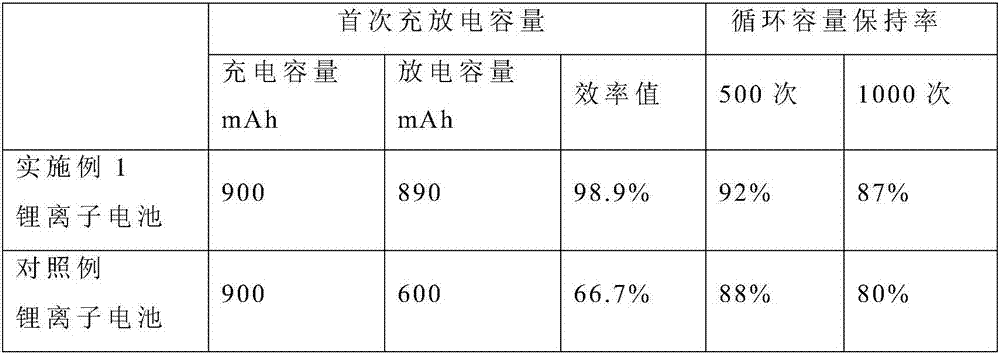

Examples

Embodiment 1

[0030] (1) Weigh 985 parts by weight of Cu metal and 15 parts by weight of Li metal in proportion. The two metals are smelted at 1100°C to 1300°C, cast into ingots in a protective atmosphere, pickled and peeled to obtain a clean surface; then the ingots with clean surfaces are homogenized, and the homogenized cast The ingot was forged at high temperature and rolled into a metal foil with a thickness of 20 μm, which was used as the negative electrode collector.

[0031] (2) Take 1 part by weight of graphene (900mAh / g), 0.05 parts by weight of PVDF, and 1 part by weight of NMP, mix them evenly, and apply them on the aforementioned 20μm thick, surface area of 372cm 2 The surface of the Cu-Li alloy foil is dried and pressed into the negative electrode sheet for the battery.

[0032] (3) Take 6 parts by weight of positive electrode active material LiFePO4 (150mAh / g), 0.3 parts by weight of conductive carbon black, 0.2 parts by weight of PVDF, add 6.5 parts by weight of NMP, stir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com