Drilling fluid lubricating agent composition containing lubricating capsules, preparation method of drilling fluid lubricating agent composition, water-based drilling fluid and application thereof

A technology of lubricant composition and water-based drilling fluid, which is applied in the field of drilling fluid, can solve problems such as difficulty in achieving lubricating effect, low effective concentration, and poor persistence, and achieve improved oxidation stability and lubricating performance, excellent lubricating performance, The effect of rich sources of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] According to the present invention, the preparation method of the capsule particles includes the following steps:

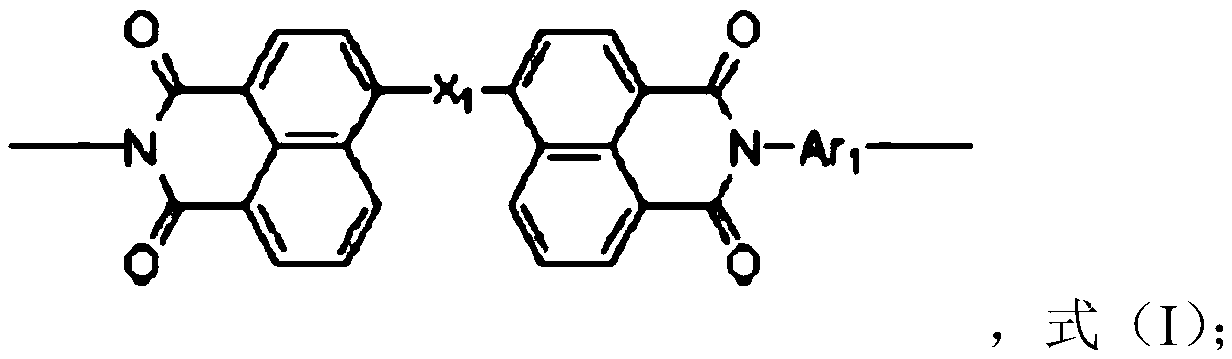

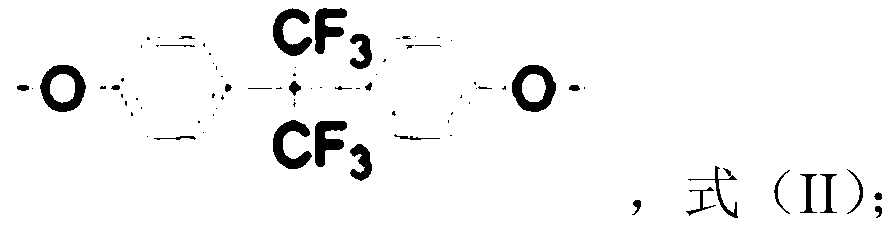

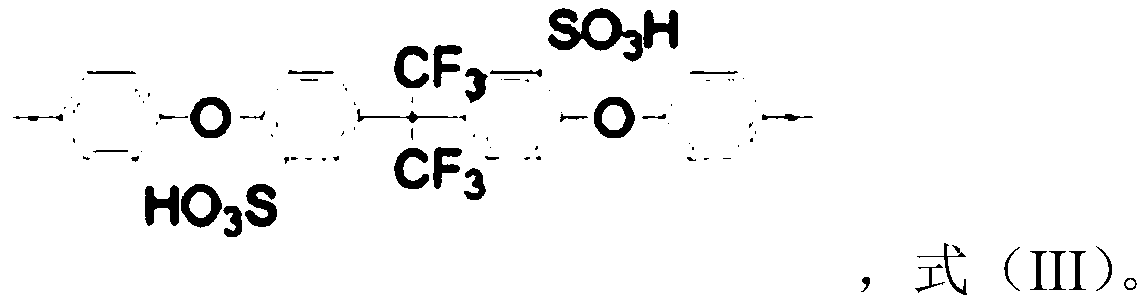

[0033] (a) Under the protection of nitrogen, the starch and distilled water are gelatinized, and then sulfonated polyimide, dimethyl diallyl ammonium chloride and cerium ammonium nitrate are sequentially added for polymerization;

[0034] (b) The lubricating substance and the capsule membrane prepolymer obtained in step (a) are reacted at a constant temperature.

[0035] In step (a), under the protection of nitrogen, add starch and distilled water into a four-necked flask, gelatinize at 80-95°C for 20-30 minutes while stirring uniformly, control the reaction temperature to 30-40°C, and then add sulfur Polyimide, dimethyl diallyl ammonium chloride and cerium ammonium nitrate are stirred and reacted for 1-2 hours to obtain a capsule prepolymer with a total concentration of 3-7 wt%;

[0036] Preferably, the stirring is carried out under the condition that the stirrin...

Embodiment 1

[0093] This example is used to illustrate the preparation of lubricant compositions and water-based drilling fluids by the method of the present invention.

[0094] The drilling fluid lubricant composition of this embodiment includes the following components and parts by weight: 96 parts by weight of capsule particles, 2 parts by weight of extreme pressure antiwear agent, 4 parts by weight of dispersant, and 3 parts by weight of defoamer.

[0095] Wherein, the capsule includes a capsule membrane and a lubricating substance placed in the capsule membrane. The lubricating substance includes the following components and parts by weight: 32 parts by weight of modified vegetable oil, 48 parts by weight of biodiesel, 5 parts by weight of surfactant, and polyol The nonionic emulsifier is 3 parts by weight; the surfactant is polyoxyethylene laureth ether, and the polyol nonionic emulsifier is sorbitan diester.

[0096] In this embodiment, the modified vegetable oil is epoxy-modified rapeseed...

Embodiment 2

[0118] This example is used to illustrate the preparation of lubricant compositions and water-based drilling fluids by the method of the present invention.

[0119] The drilling fluid lubricant composition of the present embodiment is prepared with the following components and parts by weight of raw materials: 96 parts by weight of capsule particles, 2 parts by weight of extreme pressure antiwear agent, 4 parts by weight of dispersant, and 3 parts by weight of defoamer.

[0120] Wherein, the capsule includes a capsule membrane and a lubricating substance placed in the capsule membrane. The lubricating substance includes the following components and parts by weight: 40 parts by weight of modified vegetable oil, 50 parts by weight of biodiesel, 6 parts by weight of surfactant, and polyol 4 parts by weight of nonionic emulsifier. The surfactant is lauryl alcohol polyvinyl ether, and the polyol nonionic emulsifier is sorbitan monopalmitate.

[0121] In this embodiment, the modified vege...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flash point | aaaaa | aaaaa |

| Kinematic viscosity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com