Aluminum base blocking treatment agent for drilling fluid and preparation method thereof

A drilling fluid and treatment agent technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of low compatibility and affect the rheological properties of drilling fluids, achieve easy industrialization, enhance wellbore stability, The effect of easy control of reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

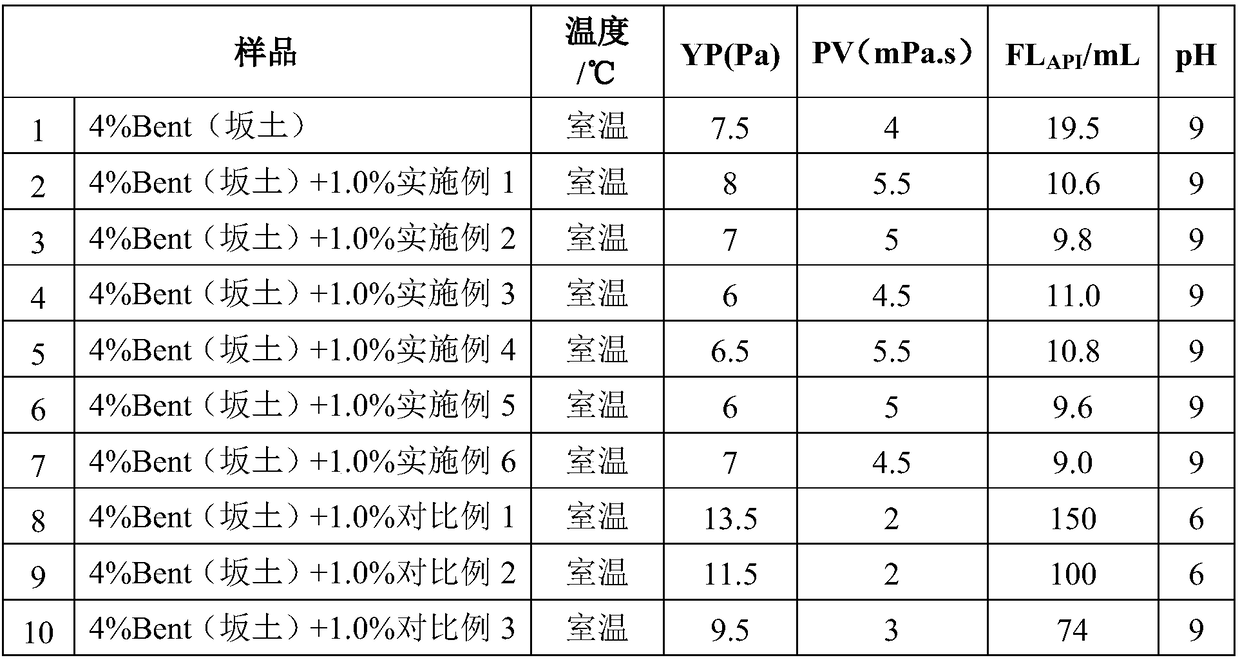

Examples

Embodiment 1

[0022] In a 250mL three-necked bottle, add 50g AlCl 3 ·6H 2 0. 50mL of water, temperature controlled to 40°C, dropwise added 5% NaOH solution through the dropping funnel for neutralization reaction until the pH was 7, after full reaction for 1h, the temperature was raised to 80°C, and 0.8g of stearic acid and 0.2 g sodium dodecylbenzene sulfonate, 0.25 g sodium carboxymethyl starch, react for 0.5 h, and cool down to room temperature to obtain 150 mL of aluminum-based plugging treatment agent for liquid drilling fluid.

Embodiment 2

[0024] In a 250mL three-necked bottle, add 50g Al 2 (SO 4 ) 3 18H 2 0. 50mL water, temperature control 80°C, neutralize by adding 40% NaOH solution dropwise through the dropping funnel to make the pH of the reaction solution 8, after fully reacting for 0.5h, continue to control the temperature at 10°C, add 5g magnesium stearate, 1g Sodium carboxymethyl cellulose, after reacting for 6 hours, 135mL of aluminum-based plugging treatment agent for liquid drilling fluid can be obtained.

Embodiment 3

[0026] In a 250mL three-necked bottle, add 50g KAl(SO 4 ) 2 12H 2 O, 50mL water, temperature control 10°C, dropwise add 30% KOH solution through the dropping funnel to neutralize to pH 7, after fully reacting for 24h, heat up to 50°C, add 0.25g sodium pyrophosphate, 0.1g xanthan gum in turn After reacting for 1 hour, 140 mL of aluminum-based plugging treatment agent for liquid drilling fluid can be obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com