Low-viscosity solvent-free epoxy graphene glass-flake coating and preparation method thereof

A glass flake coating and glass flake technology, applied in epoxy resin coating, anti-corrosion coating, coating, etc., can solve the problems of multiple coating processes, high construction thickness requirements, unsatisfactory anti-corrosion performance, etc., and achieve a strong viscosity-reducing effect , improved anti-corrosion performance, and good anti-sag performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

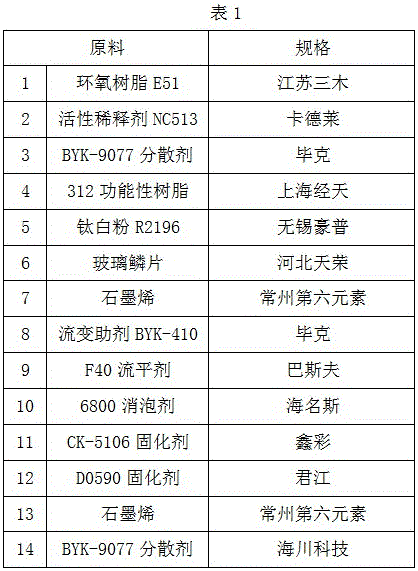

[0033] Embodiment 1: the preparation of low-viscosity solvent-free epoxy graphene glass flake coating

[0034] Component 1 Prepare raw materials according to the following mass percentages: E51 epoxy resin 37%, NC513 reactive diluent 4%, BYK-9077 dispersant 0.2%, 312 functional resin 23%, R2196 titanium dioxide 15%, glass flakes 20%, graphene 0.2%, BYK-410 rheology additive 0.2%, F40 leveling agent 0.2%, 6800 defoamer 0.2%; the fineness of glass flakes is 500 mesh;

[0035] Component two curing agent prepares raw materials according to the following mass percentages: CK-5106 curing agent 94%, D0590 curing agent 5.6%, graphene 0.2%, BYK-9077 dispersant 0.2%;

[0036] The preparation method comprises the following steps:

[0037] Component one preparation method:

[0038] A. At 200 rpm, add E51 resin, NC-513 active diluent, and 312 functional resin into a clean stirring tank, and stir evenly;

[0039] B. Add BYK-9077 dispersant and 6800 defoamer in sequence under stirring at 50...

Embodiment 2

[0046] Embodiment 2: the preparation of low-viscosity solvent-free epoxy graphene glass flake coating

[0047] Component 1 Prepare raw materials according to the following mass percentages: E51 epoxy resin 37.2%, NC513 reactive diluent 2%, BYK-9077 dispersant 0.6%, 312 functional resin 22%, R2196 titanium dioxide 14%, glass flakes 22.8%, graphene 0.3%, BYK-410 rheology additive 0.5%, F40 leveling agent 0.4%, 6800 defoamer 0.2%; the fineness of glass flakes is 400 mesh;

[0048] Component two curing agent prepares raw materials according to the following mass percentages: CK-5106 curing agent 88%, D0590 curing agent 9.5%, graphene 1.5%, BYK-9077 dispersant 1%;

[0049] The preparation method comprises the following steps:

[0050] Component one preparation method:

[0051] A. At 400 rpm, add E51 resin, NC-513 active diluent, and 312 functional resin into a clean stirring tank, and stir evenly;

[0052] B. Add BYK-9077 dispersant and 6800 defoamer in sequence under stirring a...

Embodiment 3

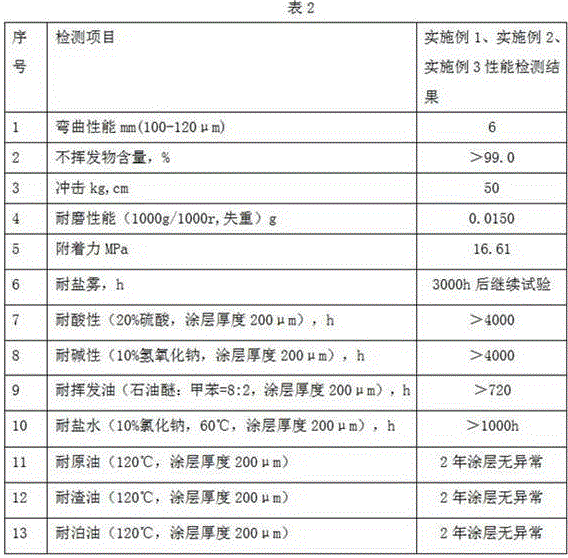

[0059] Embodiment 3: the preparation of low viscosity solvent-free graphene epoxy glass flake coating

[0060] Component 1 Prepare raw materials according to the following mass percentages: E51 epoxy resin 40%, NC513 reactive diluent 3.5%, BYK-9077 dispersant 0.2%, 312 functional resin 15%, R2196 titanium dioxide 15%, glass flakes 25%, graphene 0.2%, BYK-410 rheology additive 0.2%, F40 leveling agent 0.3%, 6800 defoamer 0.6%; the fineness of glass flakes is 300 mesh;

[0061] Component two curing agent prepares raw materials according to the following mass percentages: CK-5106 curing agent 75%, D0590 curing agent 24.2%, graphene 0.3%, BYK-9077 dispersant 0.5%

[0062] The preparation method comprises the following steps:

[0063] Component one preparation method:

[0064] A. At 500 rpm, add E51 resin, NC-513 active diluent, and 312 functional resin into a clean stirring tank, and stir evenly;

[0065] B. Add BYK-9077 dispersant and 6800 defoamer in sequence under stirring a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com