Double-fiber fine blocking agent along with drilling, and preparation method thereof

A fiber and while-drilling technology, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of high cost, complicated process, and leak prevention, and achieve the effects of low cost of use, simple preparation process, and leak prevention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

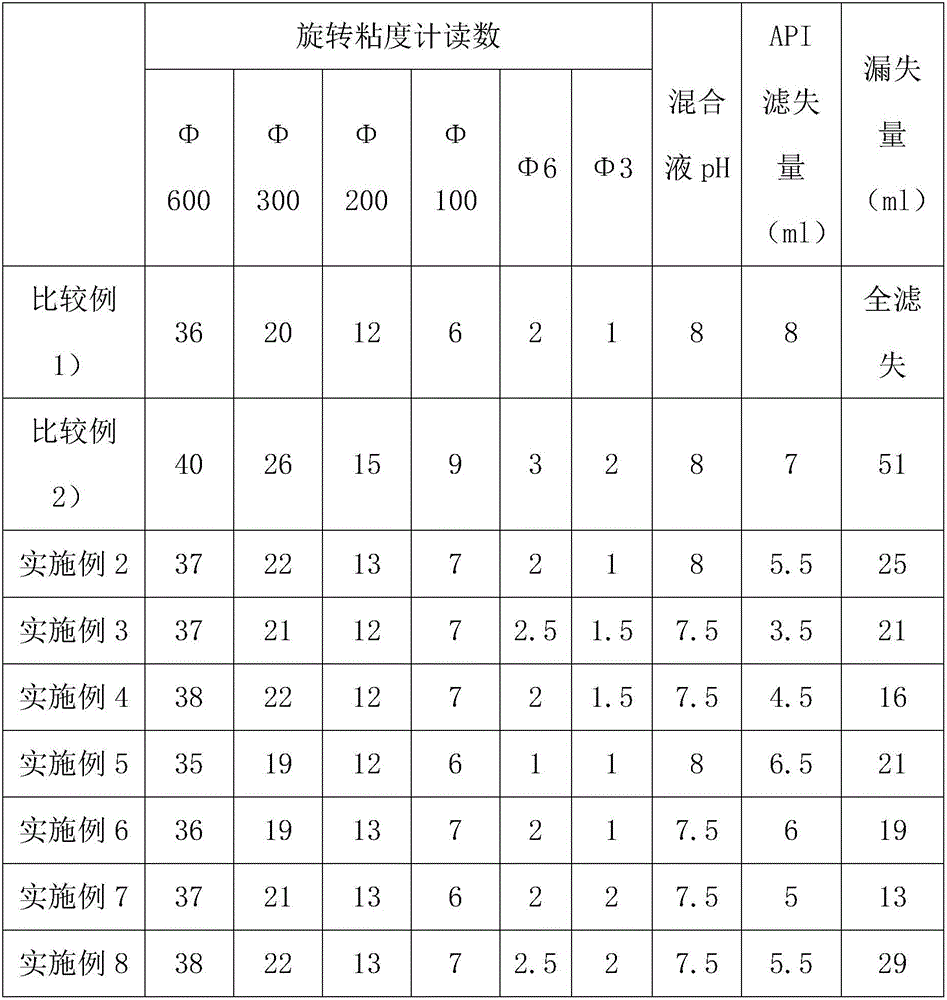

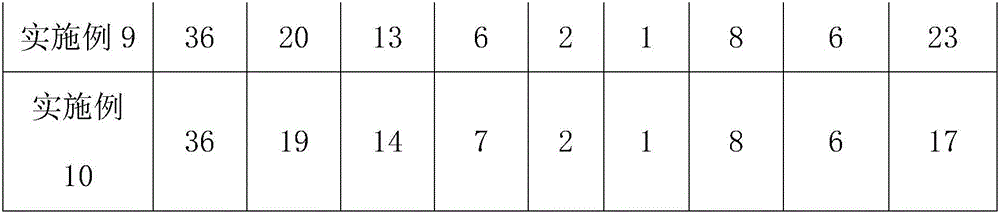

Examples

Embodiment 1

[0021] In order to overcome the existing problems, the present invention proposes a dual-fiber fine plugging agent while drilling, which includes the following components: 100 parts mica, 30-80 parts wood fiber, and 20-60 parts brucite fiber in parts by mass.

[0022] The mica is one or more of sericite, muscovite, phlogopite, lepidolite, and biotite. Mica is used as filling particles in the dual-fiber while drilling fine plugging agent of the present invention, and is filled in the gaps of the network skeleton formed by long fibers to form denser slugs and reduce drilling fluid and free water penetrating into the formation. According to the size of the pores of the fiber grid and the formation pores or microcracks, the particle size of mica is generally required to be 20-100 mesh.

[0023] The wood fiber is one or more of poplar fiber, willow fiber, pear tree fiber, and locust tree fiber. The wood fiber is a fluffy long fiber with strong flexibility, and plays a role in the skele...

Embodiment 2

[0034] This embodiment provides a dual-fiber fine plugging agent while drilling, which includes the following components: 100 parts sericite, 80 parts poplar fiber, and 60 parts brucite fiber in parts by mass.

[0035] The preparation method of the dual-fiber fine plugging agent while drilling is as follows:

[0036] Step 1) Crush 100 parts of sericite to a particle size of 20-100 mesh;

[0037] Step 2) Soak 80 parts of the trunk and branches of poplar trees in hydrochloric acid with a mass concentration of 25% and a temperature of 95°C. After soaking for 12 hours, wash the acidified trunk and branches with water to a pH of 7, and then dry them. The trunk and branches of poplar trees are crushed to a particle size of 20-40 mesh to obtain poplar fibers;

[0038] Step 3) pulverize 60 parts of brucite fiber to a fiber length of 1-5mm;

[0039] Step 4) 100 parts of sericite, 80 parts of poplar fiber and 60 parts of brucite fiber are mixed uniformly with a kneader to obtain a dual-fiber fin...

Embodiment 3

[0042] This embodiment provides a dual-fiber fine plugging-while-drilling agent as described in Example 2. The dual-fiber fine-plugging-while-drilling agent is mixed with drilling fluid, and the dual-fiber MWD is added at one time per cubic meter of drilling fluid. The mass of the fine plugging agent is 50kg.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com