High-temperature-resistant while-drilling plugging agent and preparation method thereof

A technology of plugging while drilling and resisting high temperature, applied in chemical instruments and methods, drilling composition, etc., can solve problems such as reducing fluid loss, reduce fluid loss, maintain wellbore stability, and avoid repeatability missing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Dissolve 0.3g of cetyltrimethylammonium bromide in 30mL of water, add 70g of styrene, 3.5g of divinylbenzene, and 3.0g of azobisisobutyronitrile under continuous stirring The mixture of initiator and 3.6g of cumene peroxide initiator, after the addition of the emulsion to form an emulsion, raise the temperature of the system to 50°C, after 8 hours of polymerization to obtain the powder, weigh 10.0g of the powder and add it to 5.0g of n-octanol in; then 1.5g of acrylamide and 1.0g of N'N-methylenebisacrylamide were dissolved in 15.0mL of aqueous solution, added to the polystyrene powder swollen by n-octanol for 2 hours, and mixed evenly, Add 0.20 g of ferrous sulfate in 5.0 mL of aqueous solution under stirring, and the reaction is completed within 3 minutes to obtain a high-temperature resistant LWD plugging agent.

Embodiment 2

[0031] Dissolve 0.3g of cetyltrimethylammonium bromide in 30mL of water, add 70g of styrene, 7.0g of divinylbenzene, and 3.0g of azobisisobutyronitrile under continuous stirring The mixed solution of initiator and 3.6g of hydroxycumene peroxide initiator, after the feeding is completed to form an emulsion, the system is warmed up to 55°C, after 7 hours of polymerization to obtain powder, weigh 10.0g of powder and add it to 6.0g of n-octanol in; then 1.5g of acrylamide and 1.0g of N'N-methylenebisacrylamide were dissolved in 15.0mL of aqueous solution, added to the polystyrene powder swollen by n-octanol for 5h, after mixing evenly, Add 0.20 g of ferrous sulfate in 5.0 mL of aqueous solution under stirring, and the reaction is completed within 3 minutes to obtain a high-temperature resistant LWD plugging agent.

Embodiment 3~7

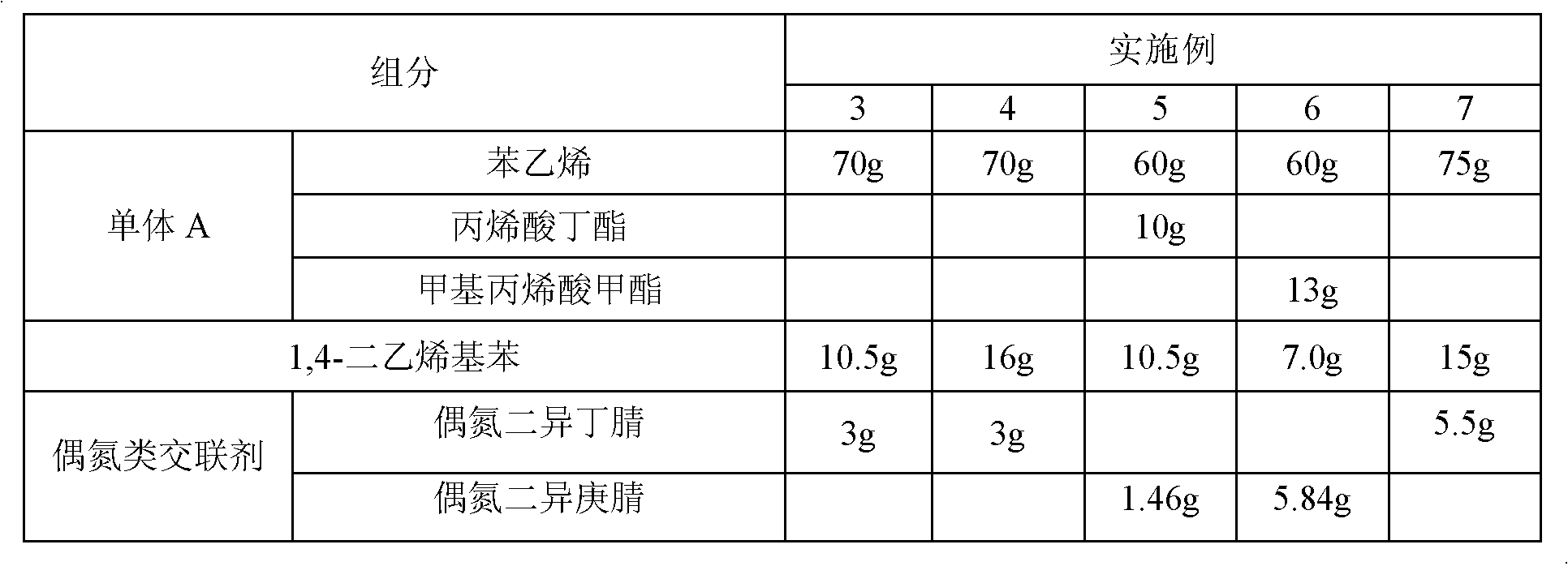

[0032] Embodiment 3~7: step is identical with embodiment 1, and reactant and consumption table are as shown in table 1:

[0033] Table 1 Example of a high temperature resistant LWD plugging agent and its preparation method

[0034]

[0035]

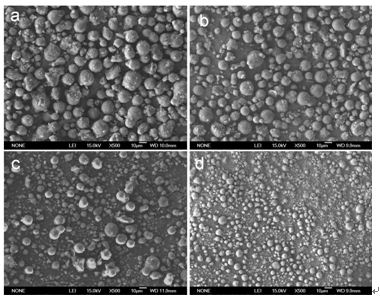

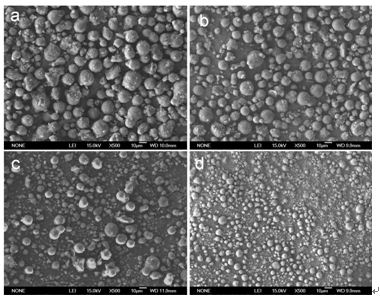

[0036] After drying the LWD plugging agent obtained in Examples 1, 2, 3, and 4, the surface is sprayed with gold, and its microscopic morphology is observed under a scanning electron microscope as follows: figure 1 Middle a, b, c, d. Depend on figure 1 It can be seen that the particle size of the anti-high temperature LWD plugging agent obtained in the present invention is micron-scale, and the particle size is distributed between 2-25 μm; by adjusting the amount of oil-soluble cross-linking agent D, high-temperature anti-WD with different particle sizes can be obtained. It is a leak-stopping agent that can expand in volume when it meets water and oil, and can be used to plug a wide range of micro-cracks and pores.

[0037] Add t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com