Hydrocarbon reservoir protective agent and preparing method thereof

A protective agent, oil and gas layer technology, applied in the field of drilling, can solve problems such as poor sealing performance, poor elasticity and rigidity, and inability to effectively protect oil and gas layers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

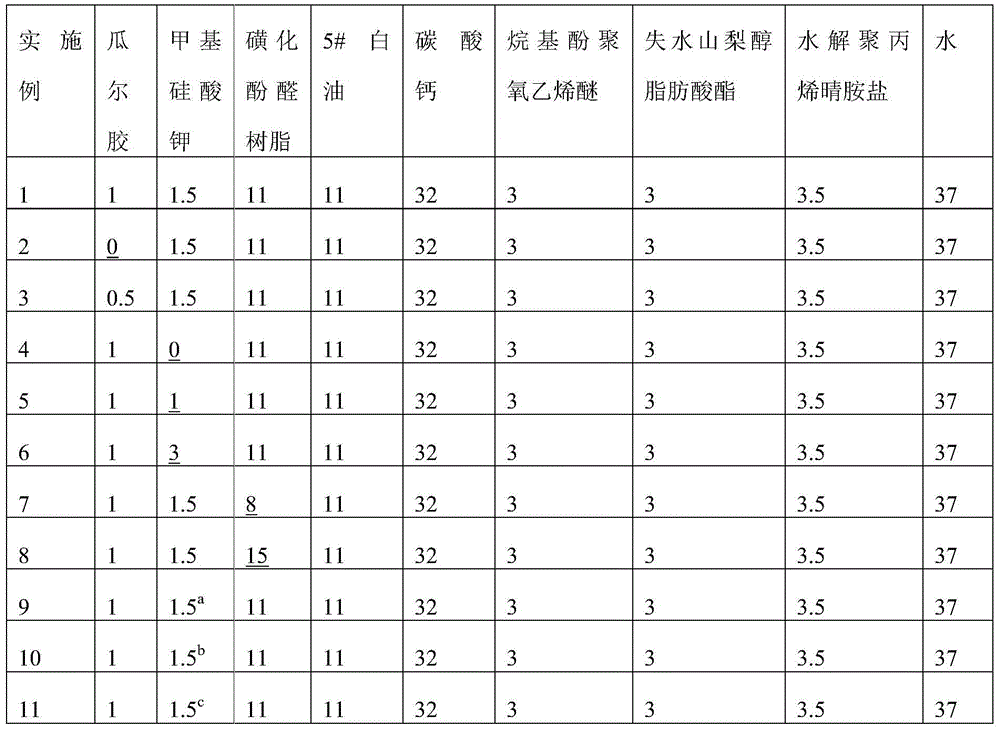

Embodiment 1

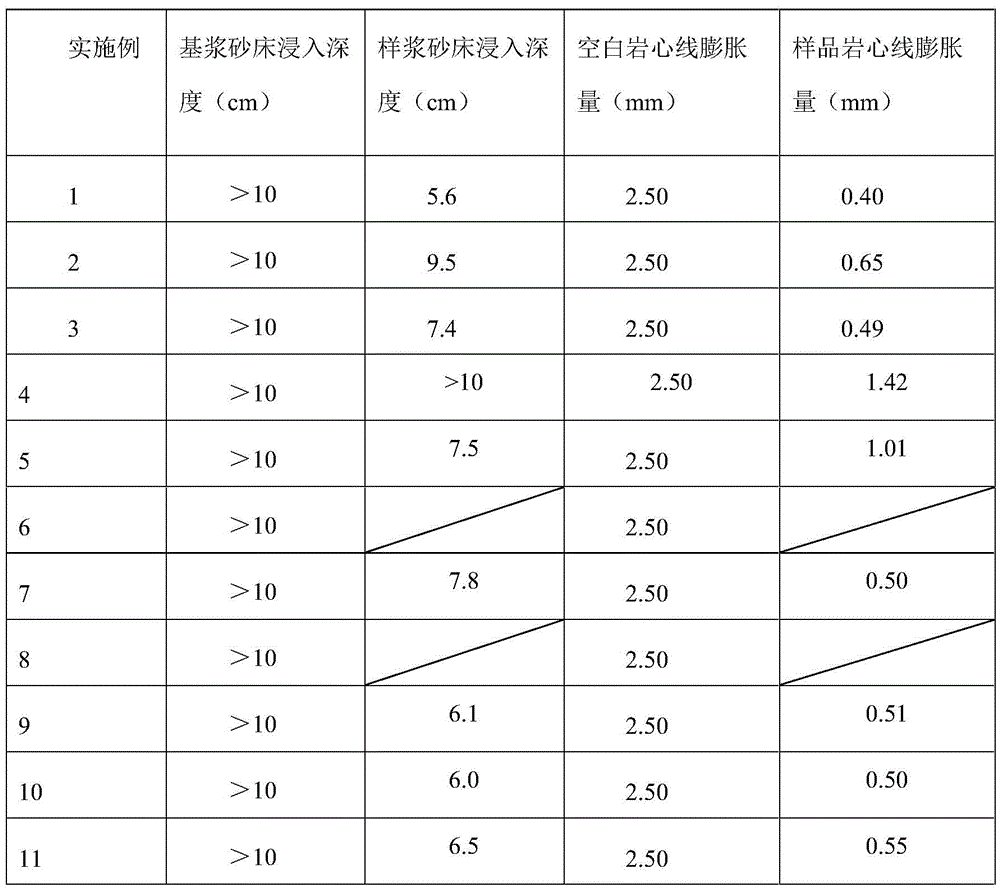

[0048]Get 1 part (parts by weight, the same below) as sulfonic acid carboxymethyl guar gum of guar gum, 11 parts of 5# white oil as white oil, 3 parts of alkylphenol polyoxyethylene ether as alkylphenol polyoxyethylene ether Oxyethylene ether-10, 3 parts of sorbitan oleate as sorbitan fatty acid ester were dissolved in 37 parts of water. Heat to 70°C and stir evenly. Adding 11 parts of sulfomethyl phenolic resin powder-I (powder) as sulfonated phenolic resin, 32 parts of particle size is 600-1000 purpose calcium carbonate, 1.5 parts of potassium methyl silicate, 3.5 parts of hydrolysis polyacrylonitrile amine salt ( purchased from Chengdu Longyu Chemical Co., Ltd.), and stirred for 2 hours. The "oil and gas layer protection agent" can be prepared.

[0049] The immersion depth of the base slurry sand bed, the immersion depth of the sample slurry sand bed, the linear expansion of the blank core and the linear expansion of the sample core of the prepared oil and gas layer prote...

Embodiment 2

[0051] Take 0 parts of carboxymethyl guar gum sulfonate, 11 parts of 5# white oil, 3 parts of alkylphenol polyoxyethylene ether-10, and 3 parts of sorbitan oleate and dissolve them in 37 parts of water. Heat to 70°C and stir evenly. Then add 11 parts of sulfomethyl phenolic resin powder-I (powder), 32 parts of calcium carbonate with a particle size of 600-1000 mesh, 1.5 parts of potassium methyl silicate, 3.5 parts of hydrolyzed polyacrylonitrile amine salt (purchased from Chengdu Longyu Chemical Co., Ltd.), stirring for 2h. The "oil and gas layer protection agent" can be prepared.

Embodiment 3

[0053] Take 0.5 parts of carboxymethyl guar gum sulfonate, 11 parts of 5# white oil, 3 parts of alkylphenol polyoxyethylene ether-10, and 3 parts of sorbitan oleate and dissolve them in 37 parts of water. Heat to 70°C and stir evenly. Then add 11 parts of sulfomethyl phenolic resin powder-I (powder), 32 parts of calcium carbonate with a particle size of 600-1000 mesh, 1.5 parts of potassium methyl silicate, 3.5 parts of hydrolyzed polyacrylonitrile amine salt (purchased from Chengdu Longyu Chemical Co., Ltd.), stirring for 2h. The "oil and gas layer protection agent" can be prepared.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com