Ignition coil

A technology for high-voltage joints and spark plugs, which is applied in the direction of spark plugs, transformer/coil connectors, connections, etc., can solve the problems of high manufacturing costs, increase the diameter of the protective cover, and reduce the flexibility of the protective cover, so as to save manufacturing costs and reduce materials. , The effect of reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

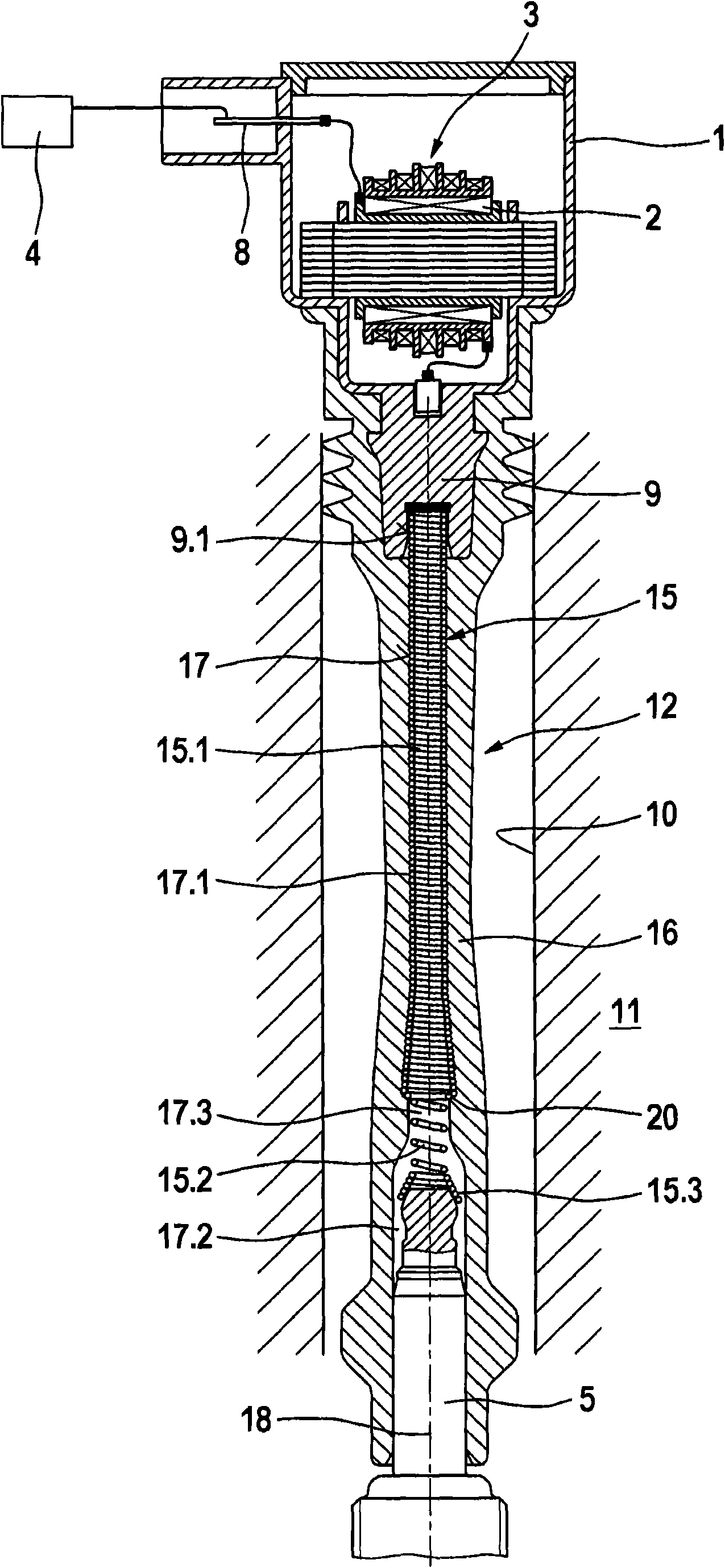

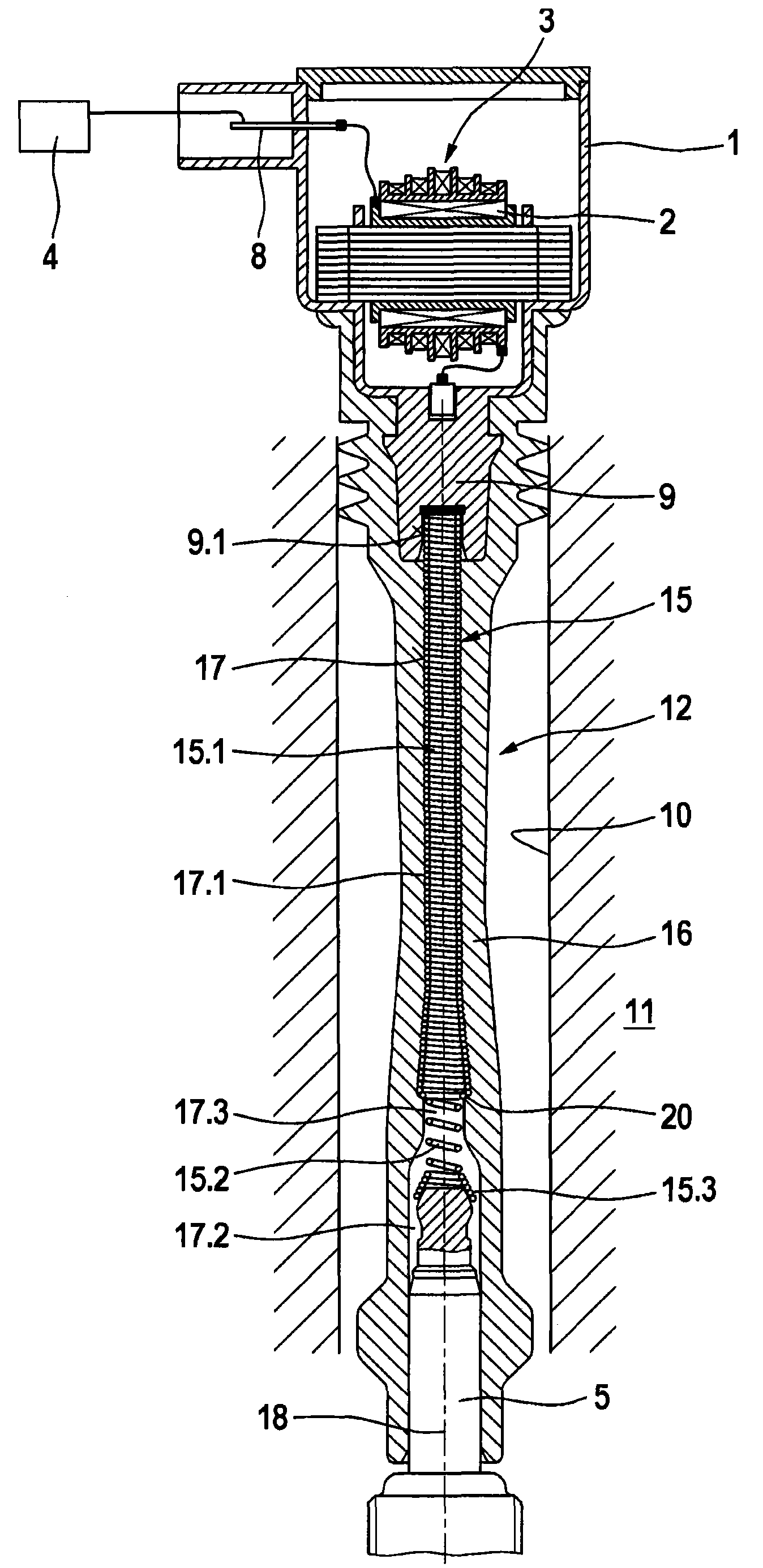

[0016] The figure shows a simplified representation of an ignition coil according to the invention in a sectional view.

[0017] The ignition coil generates the high voltage required for the spark discharge at the spark plug.

[0018] The ignition coil has a coil housing 1 in which a primary coil 2 and a secondary coil 3 cooperate in such a way that the high voltage of the spark plug 5 is generated from the low DC voltage of the battery 4 . Primary coil 2 can be electrically connected via low-voltage connection 8 to battery 4 and via high-voltage connection 9 to spark plug 5 . The high-voltage connection 9 is formed, for example, as a dome which protrudes from the coil housing 1 . The spark plug 5 is usually arranged in a shaft 10 of a cylinder head 11 of the internal combustion engine.

[0019] The ignition coil is designed as a so-called compact ignition coil, whose coil housing 1 is arranged outside the shaft 10 and whose high-voltage connection 9 is connected to the spar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com