Fibre winding method of glass fiber reinforced plastics pipeline at zero degree

A technology of glass fiber and FRP, applied in the field of zero-degree fiber winding of FRP pipes, can solve the problems of increasing hoop strength, increasing production cost, and complicated equipment, and achieve the effect of increasing hoop strength, reducing production cost, and simple production equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

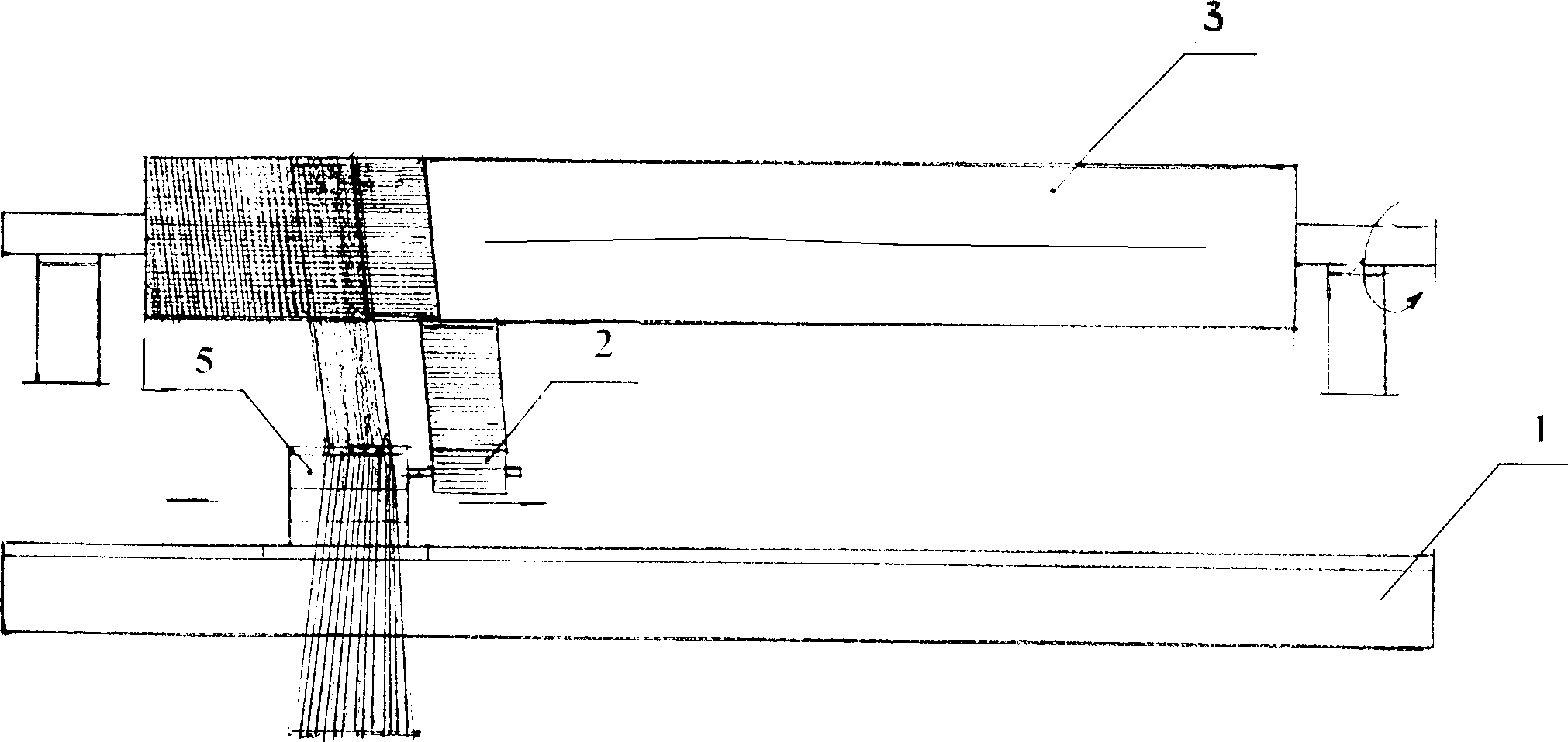

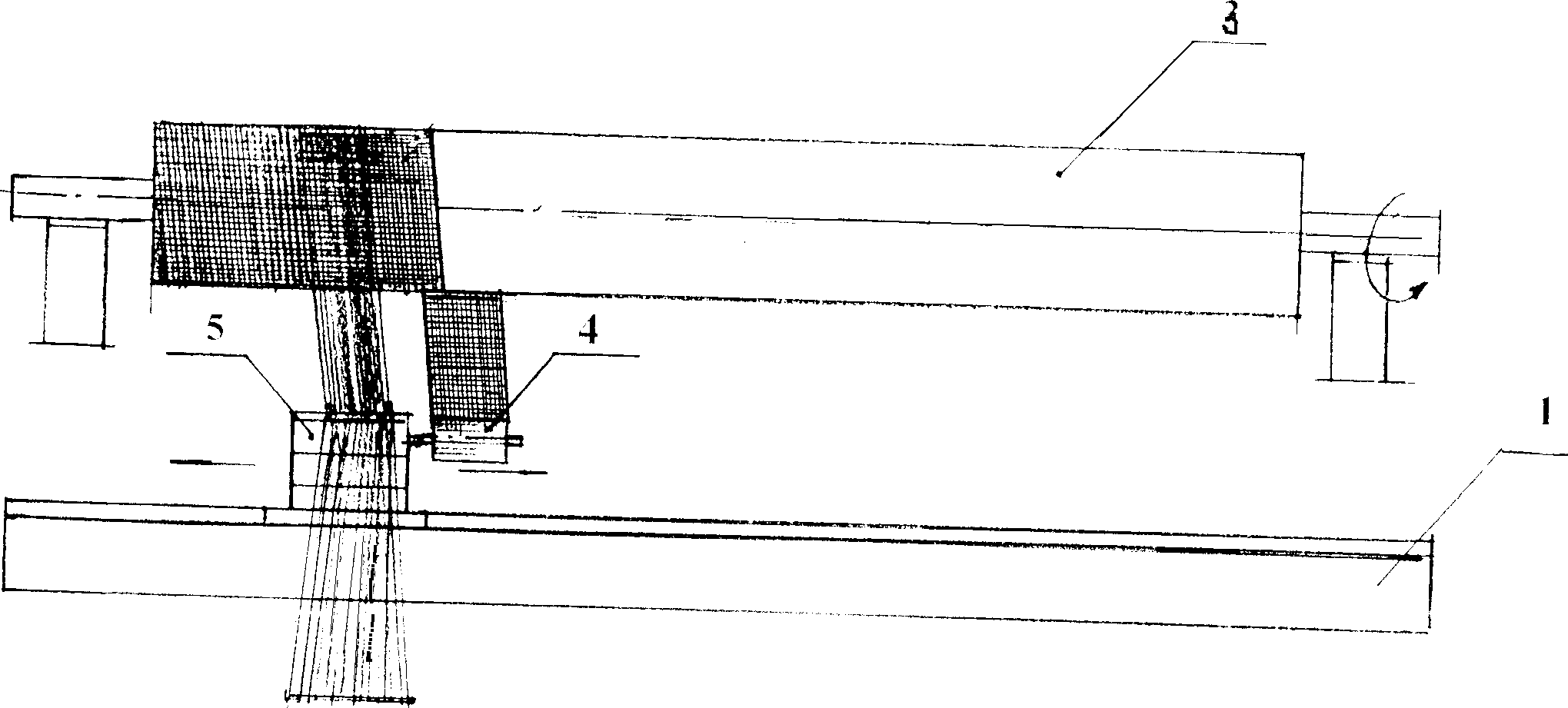

[0016] As mentioned above, since the glass fiber unidirectional cloth is made by sewing a plurality of parallel glass fibers with a certain length in a direction perpendicular to it, and the glass fiber mesh cloth is woven by vertically intersecting glass fibers. However, when the unidirectional cloth or grid cloth is used for hoop winding, the length direction of the glass fiber on the pipe is the same as the axial direction of the FRP pipe, so the axial strength of the FRP pipe can be greatly improved. Such as figure 1 , figure 2 As shown, when winding the FRP pipe, the hoop winding of the non-woven fabric and the glass fiber is performed according to the method in the prior art. 2 or the hoop winding of the grid cloth 4, that is, the glass fiber unidirectional cloth 2 or the grid cloth 4 is wound from the The tangential direction of the lower part of the FRP pipe mold 3 rotating in the direction of the workbench 1 is introduced, and it is wound on the surface of the mold...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com