Connection for well bore drilling tools

a well bore and tool technology, applied in the direction of drilling rods, drilling pipes, drilling casings, etc., can solve the problems of connection decoupling, tool joint failure, and encounter force and resistance, and achieve the effect of reducing reducing the possibility of mechanical failure or shearing, and increasing the rotational torqu

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

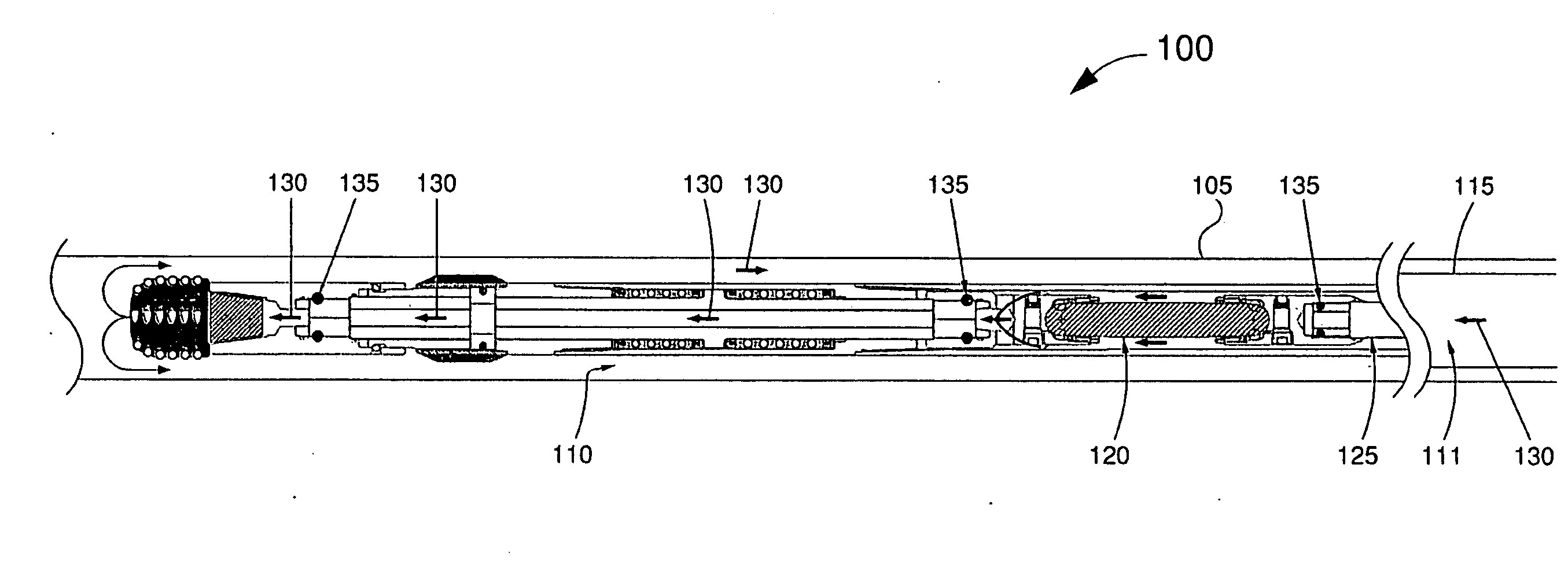

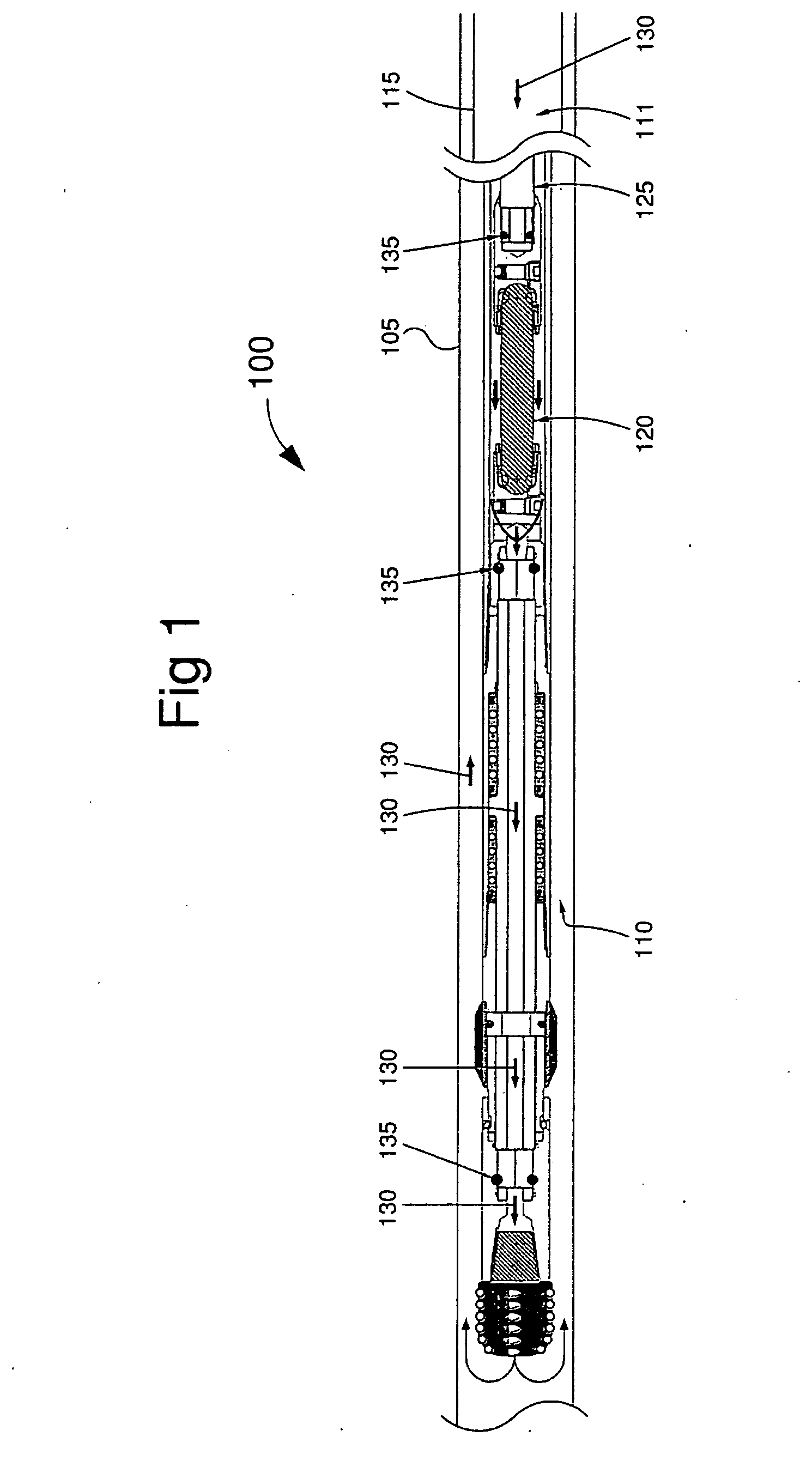

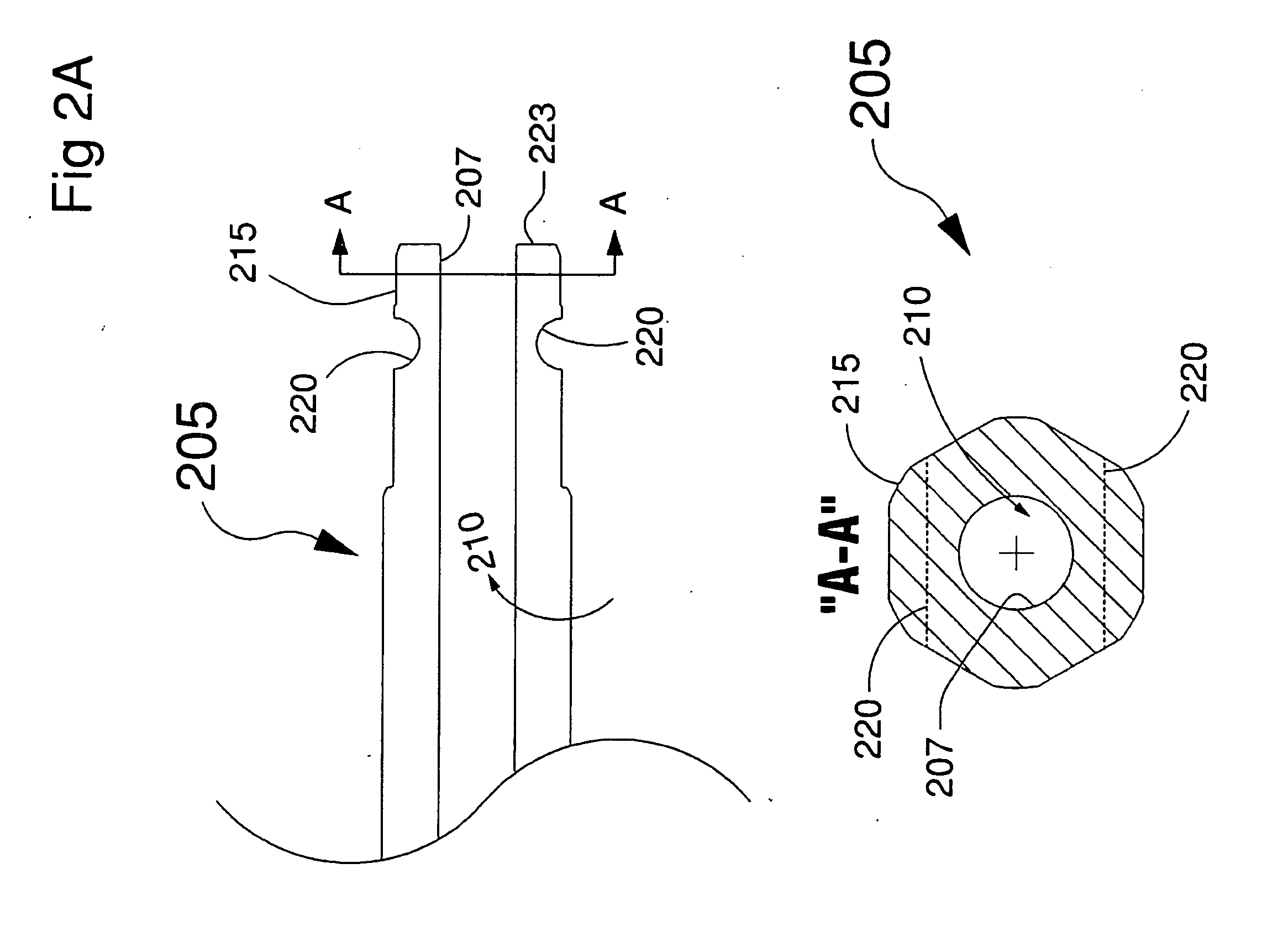

[0022]A drilling tool connection may be used to couple together various downhole drilling devices, such as downhole drilling motors, impact jars, MWD / LWD tools, drill bits, universal joint assemblies, bearing sections, drill string sections, and the like. The drilling tool connection, generally, includes a male end with an elongated pin including a longitudinal bore disposed along a longitudinal axis of the pin; a female end with a box including an aperture designed to receive the pin, and one or more locking pins designed to be inserted through apertures in the wall of the box into a semi-circular pin slot on the exterior surface of the pin, thereby securing the pin and the box together. The pin includes one or more transverse pin slots while the box includes one or more corresponding transverse semi-cylindrical box bores, such that upon insertion of the pin into the box, cylindrical apertures are created by alignment of the transverse pin slots with the corresponding transverse bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com