Magnetic control type energy-saving welding gun structure

A magnetic control, welding torch technology, applied in valve details, welding equipment, gas flame welding equipment, etc., can solve the problems of polluting the environment, wasting gas, gas leakage, etc., achieving convenient on-off control, preventing tempering, and fast response Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

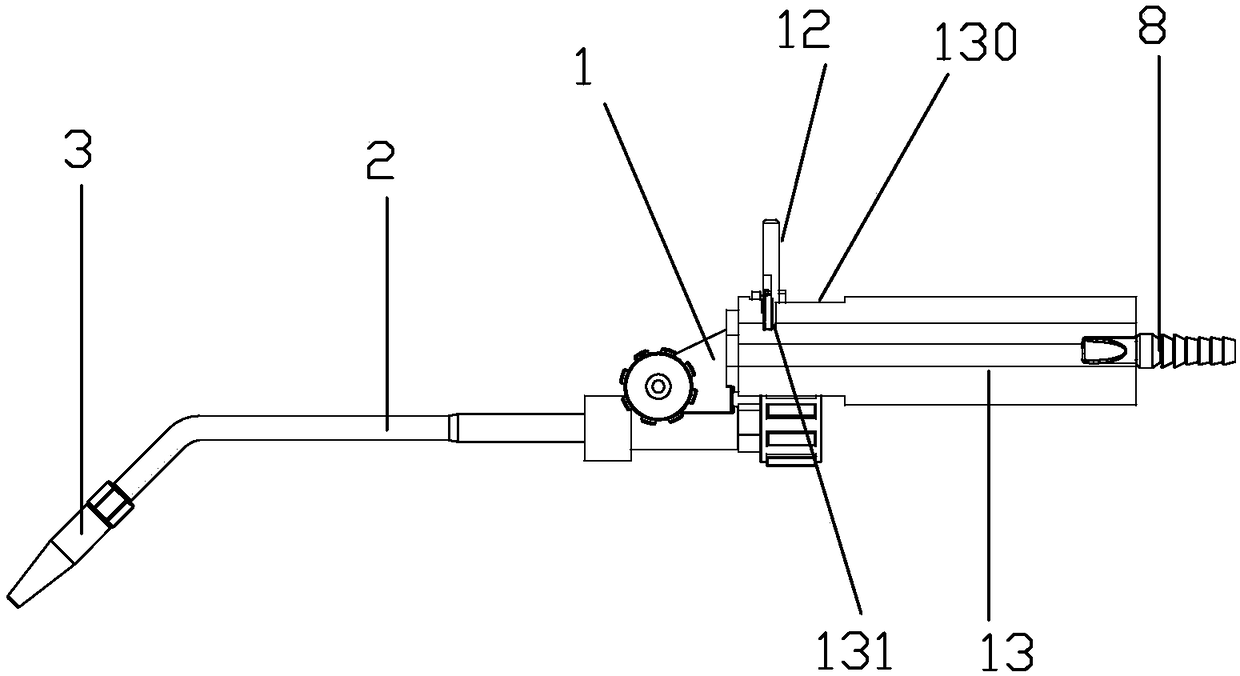

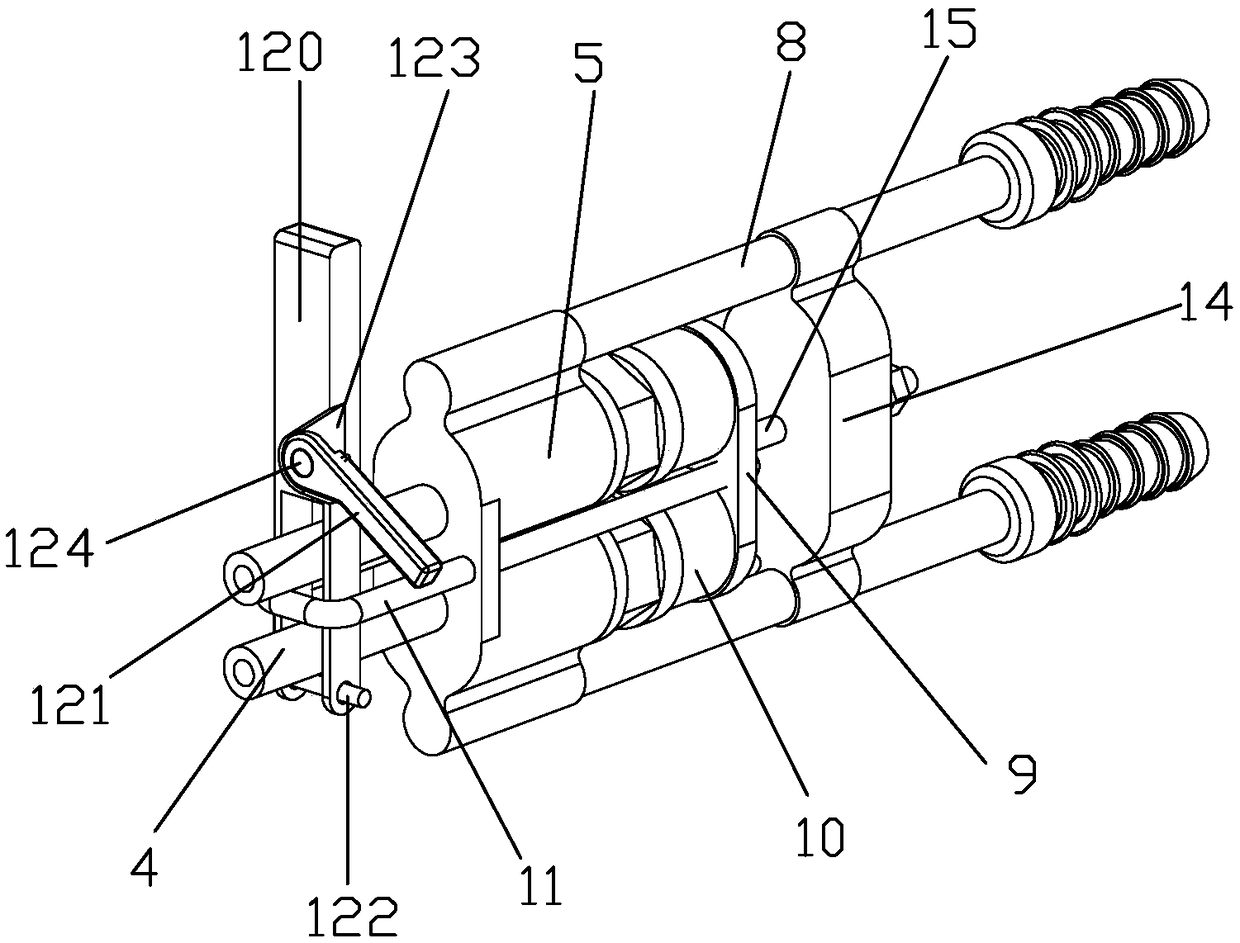

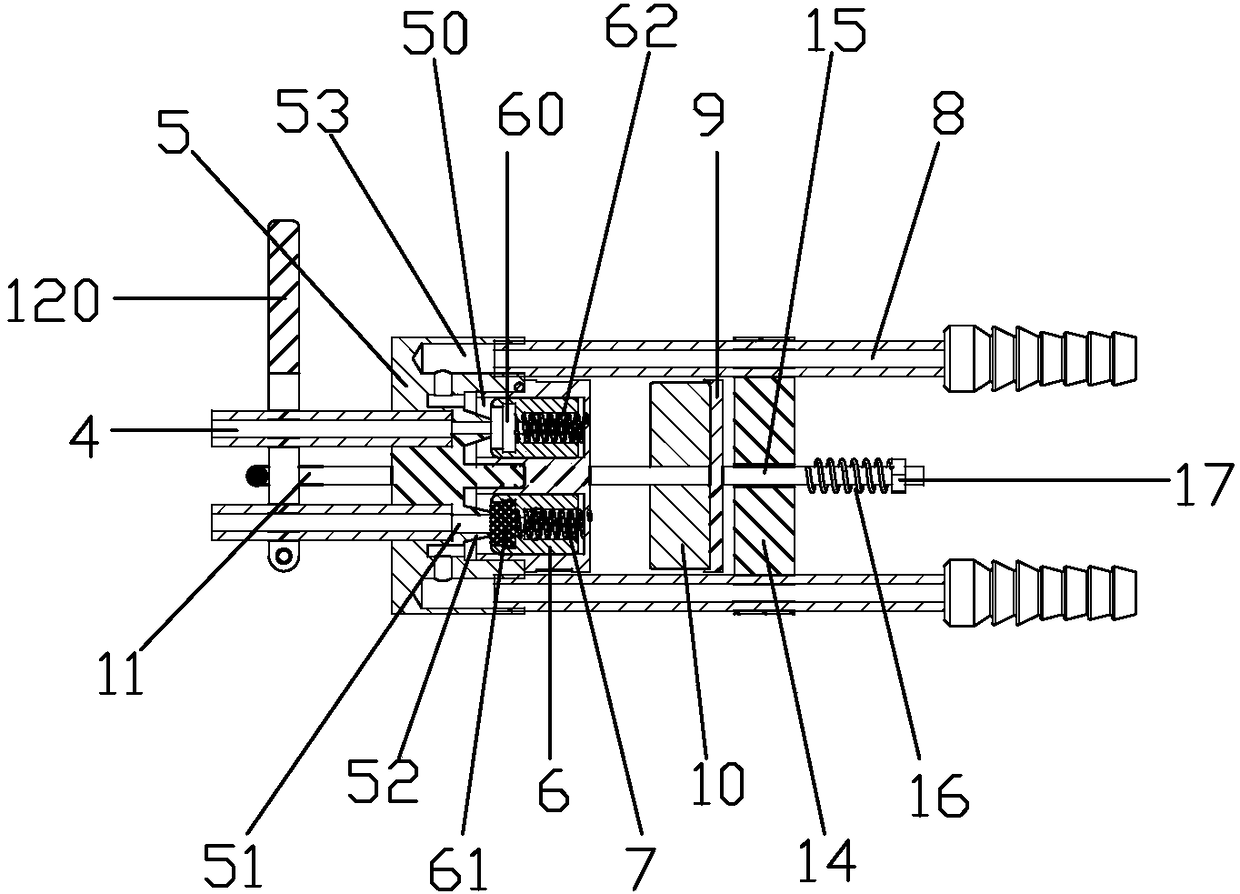

[0027] Embodiment 1: as figure 1 , figure 2 and image 3 The structure of a magnetically controlled energy-saving welding torch shown includes a connecting seat 1 and an air jet pipe 2. One end of the air jet pipe is connected to the connecting seat, the other end of the air jet pipe is provided with a welding tip 3, and the connecting seat is provided with two parallel Connecting pipe 4, the two connecting pipes communicate with the jet pipe through the flow channel in the connecting seat; the inlet end of the connecting pipe 4 is provided with a valve seat 5, and the valve seat is provided with two independent valve chambers 50, the front end of the valve seat There are two outlet air passages 51 correspondingly connected with the valve chamber, the inner end of the outlet air passage extends into the valve chamber to form a tapered convex ring 52, and the two connecting pipes are connected with the outer ends of the outlet air passage in one-to-one correspondence , the v...

Embodiment 2

[0031] Embodiment 2: as figure 1 , Figure 4 and Figure 5 A magnetically controlled energy-saving welding torch structure is shown, including a connecting seat 1 and an air jet pipe 2, one end of the air jet pipe is connected to the connecting seat, the other end of the air jet pipe is provided with a welding tip 3, and the connecting seat is provided with two parallel connecting Pipe 4, two connecting pipes communicate with the jet pipe through the flow channel in the connecting seat; the inlet end of the connecting pipe 4 is provided with a valve seat 5, and the valve seat is provided with two independent valve chambers 50, and the front end of the valve seat is provided with There are two outlet air passages 51 correspondingly connected with the valve chamber, the inner end of the outlet air passage extends into the valve chamber to form a tapered convex ring 52, two connecting pipes are connected with the outer ends of the outlet air passage one by one, There is a spool...

Embodiment 3

[0035] Embodiment 3: as figure 1 , Figure 7 and Figure 8 As shown, the difference between embodiment 3 and embodiment 1 is that: the air intake channel is located on the left and right sides of the valve seat, and the two intake pipes are respectively connected to the air intake channels on the left and right sides of the valve seat, and the rest of the structure is the same as that of embodiment 1. The structure in is consistent.

[0036] The forward movement and reset of the permanent magnet is realized by the permanent magnet forward drive mechanism and the permanent magnet reset mechanism. When the permanent magnet moves forward, it is close to the valve core, and the valve core is attracted by the magnetic force to move backward. The outlet flow channel is opened, and oxygen and gas pass through the outlet flow. When it needs to be closed, the permanent magnet moves backward away from the valve core, the magnetic force decreases, the pressure of the compression spring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com