Process for casting seal rainproof complex flanges

A composite flange and casting process technology, which is applied in the direction of manufacturing tools, casting molding equipment, casting molds, etc., can solve the problems of short production time, difficulty in ensuring the production cycle, and insufficient reserves of metallurgical accessories, so as to avoid rust and corrosion, Effect of shortening life and benefiting disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

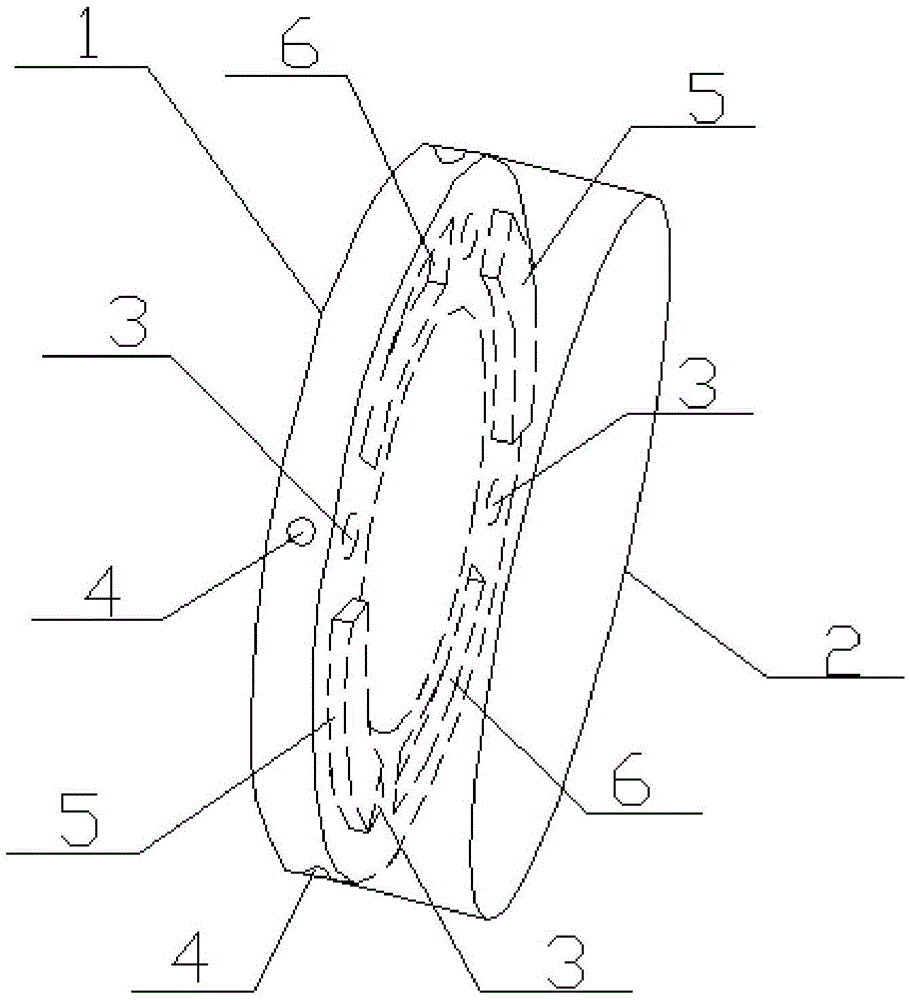

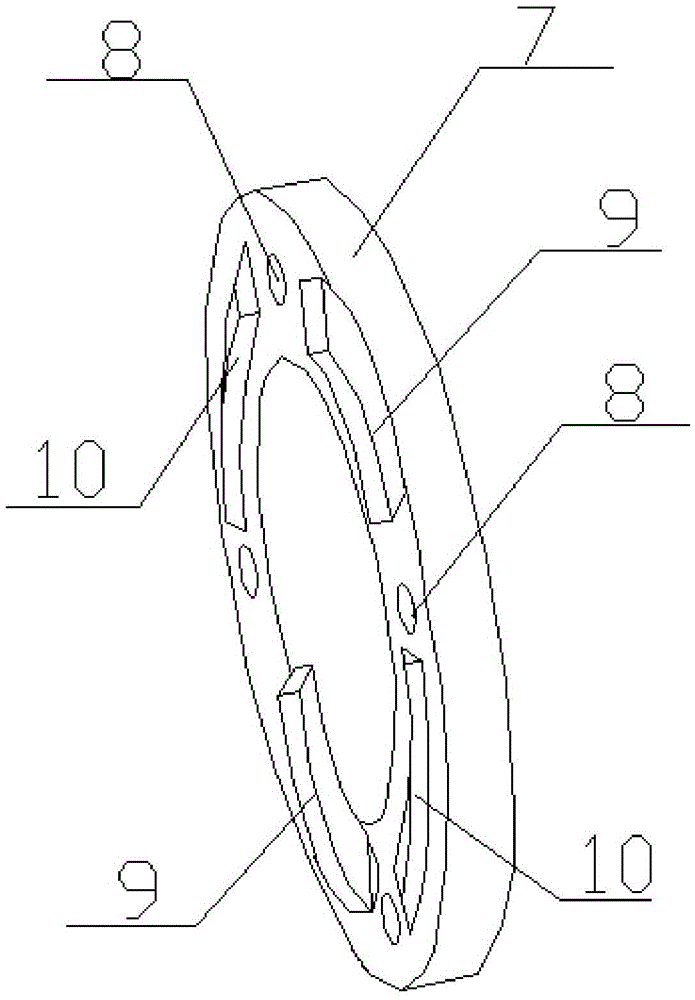

[0046] This embodiment provides a casting process for a sealed and rainproof composite flange, the structure of which is as follows figure 1 and 2 As shown, the cast composite flange includes a first flange and a second flange that are butted left and right, where:

[0047] The first flange includes a first flange body 1 and a shield 2 arranged on the first flange body 1. The shield 2 is formed by extending outward along the edge of the first flange body 1. On the first flange body 1 There are at least four first fixing holes 3 evenly distributed, the first fixing holes 3 penetrate the first flange body 1, and at least four oil injection holes 4 are evenly distributed on the first flange body 1, one oil injection hole 4 corresponds to one first flange body 1 A fixing hole 3, and the oil injection hole 4 is vertically communicated with the first fixing hole 3, and the first flange body 1 is also evenly distributed with first bumps 5 and first grooves 6 on the surface of the fi...

Embodiment 2

[0050] This embodiment provides the casting process of the sealing and rainproof composite flange in the above-mentioned embodiment 1, and the composite flange is cast. The casting process of the composite flange specifically includes the following steps:

[0051] (1) According to the size of the first flange and the second flange, the molding sand and core sand are used as molding materials to make a mold. Before making the mold, the molding sand in the molding material is first placed in an oven for drying , after drying, coat a layer of release agent on the surface of the mold;

[0052] The release agent is made of talcum powder, water, silicone oil, and vegetable oil. The parts by mass are talcum powder: 20 parts, water: 10 parts, silicone oil: 20 parts, vegetable oil: 30 parts, and then use a spray gun to release the mold The agent is sprayed on the surface of the mold cavity with a thickness of 0.05mm;

[0053] (2) Place the raw materials of the first flange and the sec...

Embodiment 3

[0065] This embodiment provides the casting process of the sealing and rainproof composite flange in the above-mentioned embodiment 1, and the composite flange is cast. The casting process of the composite flange specifically includes the following steps:

[0066] (1) According to the size of the first flange and the second flange, the molding sand and core sand are used as molding materials to make a mold. Before making the mold, the molding sand in the molding material is first placed in an oven for drying , after drying, coat a layer of release agent on the surface of the mold;

[0067] The release agent is made of talcum powder, water, silicone oil, and vegetable oil. In terms of parts by mass, it is specifically talcum powder: 30 parts, water: 20 parts, silicone oil: 30 parts, vegetable oil: 40 parts, and then use a spray gun to release the mold The agent is sprayed on the surface of the mold cavity with a thickness of 0.1mm;

[0068] (2) Place the raw materials of the f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| Brinell hardness | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com