Cleaning device for process air conditioner filter screen

A technology for cleaning devices and filter nets, which is applied in the direction of filtration separation, filter regeneration, separation methods, etc., and can solve problems such as motor damage, high labor intensity, and damage to health

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The embodiments described below by referring to the figures are exemplary only for explaining the present invention and should not be construed as limiting the present invention.

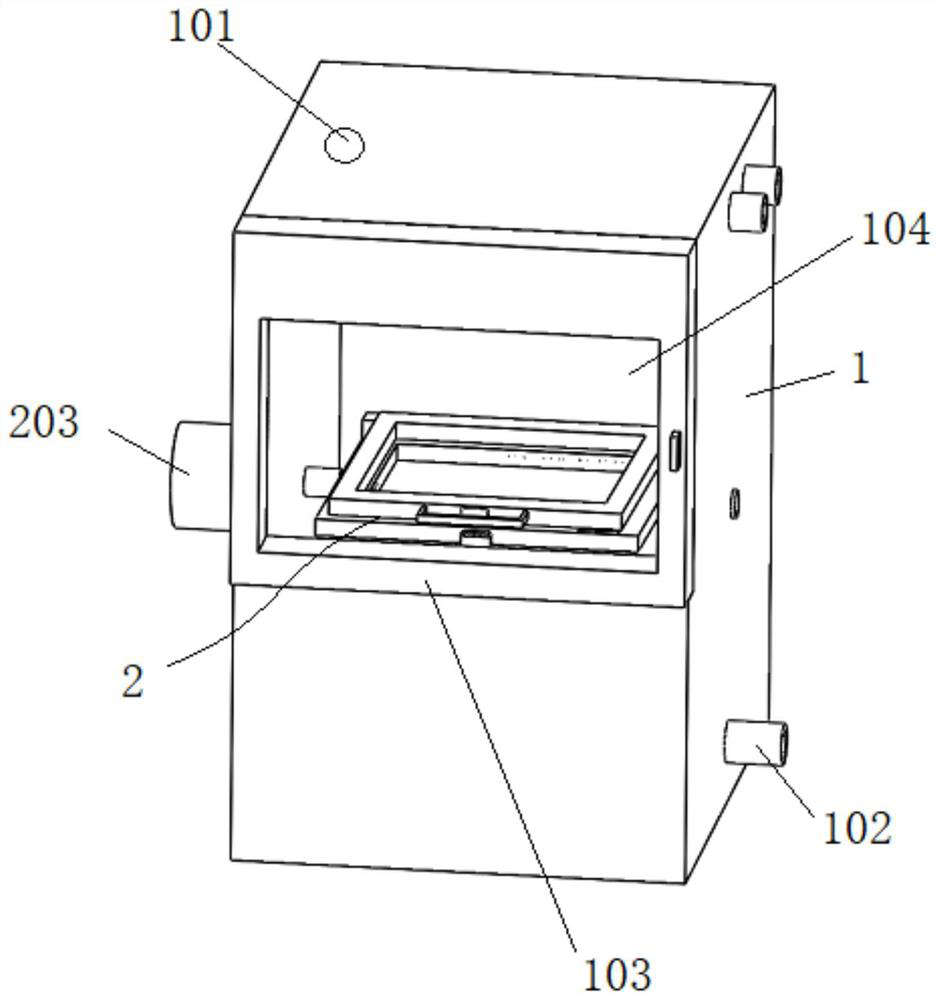

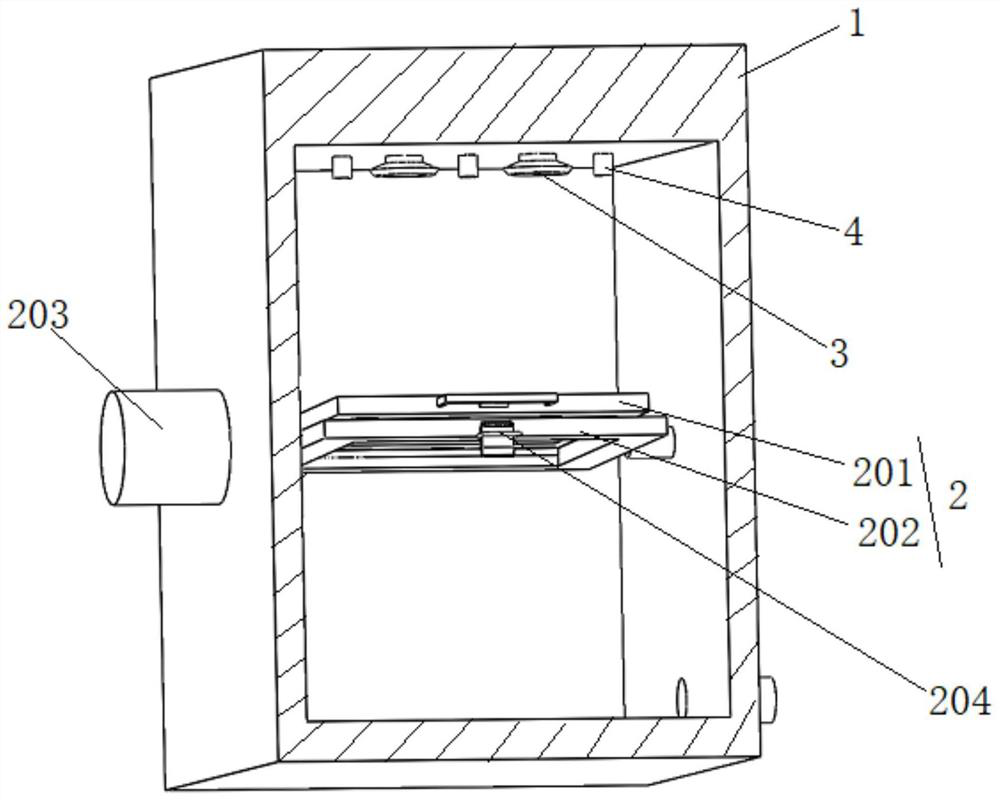

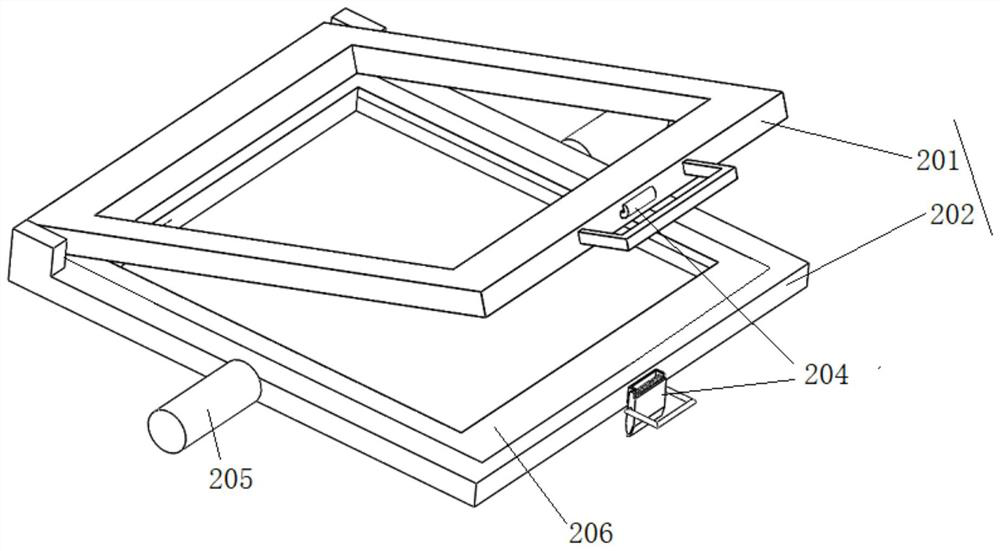

[0028] Embodiments of the present invention: as Figure 1-Figure 5 As shown, the cleaning device for the process air conditioner filter screen includes a box body 1, a filter screen mounting frame 2 is installed in the box body 1, and two water spray heads 3 and three air spray heads 4 are installed on the top of the box body 1. ; The outlet of the water spray head 3 faces the filter screen mounting frame 2, the outlet of the air spray head 4 faces the filter screen mounting frame 2, and two water spray heads 3 and three air spray heads 4 are arranged at intervals.

[0029] Description of the working process: Fix the filter to be cleaned on the filter installation frame 2, and spray high-pressure water on the filter through the water spray head 3 to clean it, and rotate the filter installatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com