Method for heat sealing small cigarette packet

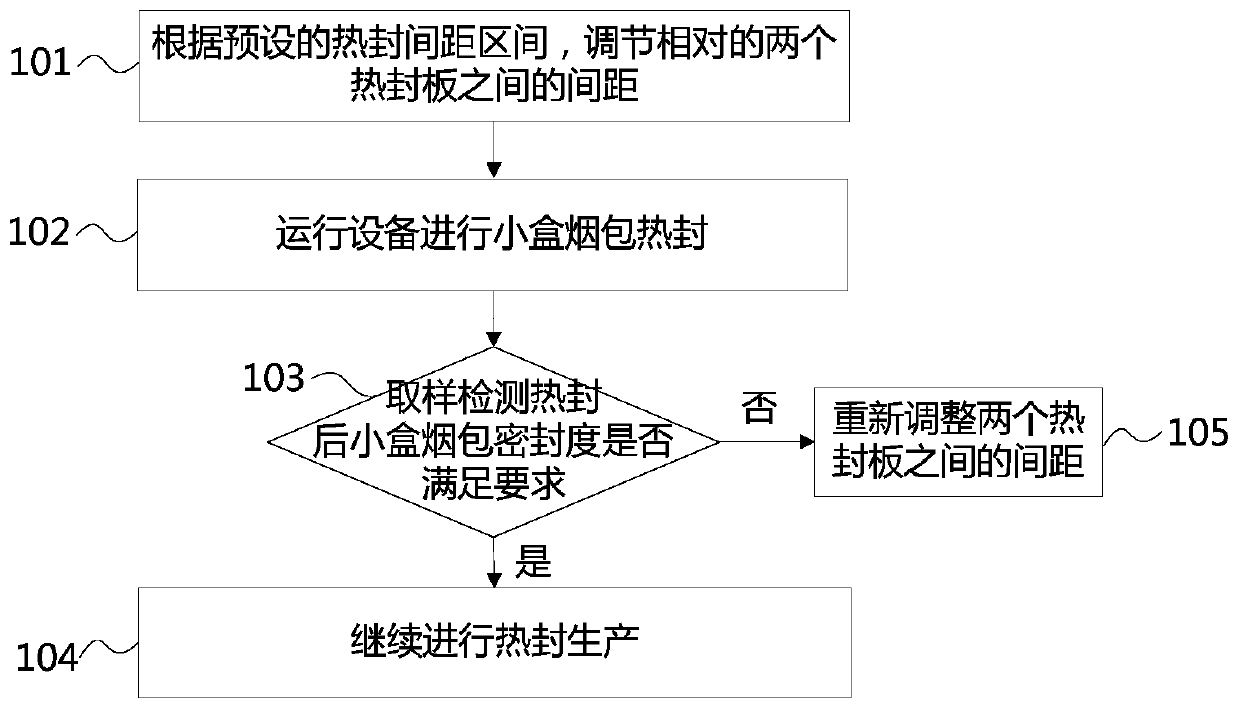

A technology for cigarette packs and packs, which is applied in packaging sealing/fastening, packaging, and packaging of cigarettes. It can solve problems such as the inability to guarantee product sealing quality and large differences in the sealing performance of small packs of cigarette packs, and improve heat-sealing production. Efficiency, quantity reduction, effect of improving airtightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0155] (1) Obtain information on the production factors of the brand, including information on equipment used, transparent paper materials, and small box trademark materials.

[0156] a. It is known that the cigarettes of this brand are produced in medium-speed equipment, and the operating speed of the equipment is 400 packs / min;

[0157] b. Using transparent paper material A, according to the melting point temperature of the transparent paper material and the heat-sealing temperature setting table information of the equipment operating speed, the corresponding heat-sealing temperature range of the transparent paper material is [144°C, 152°C];

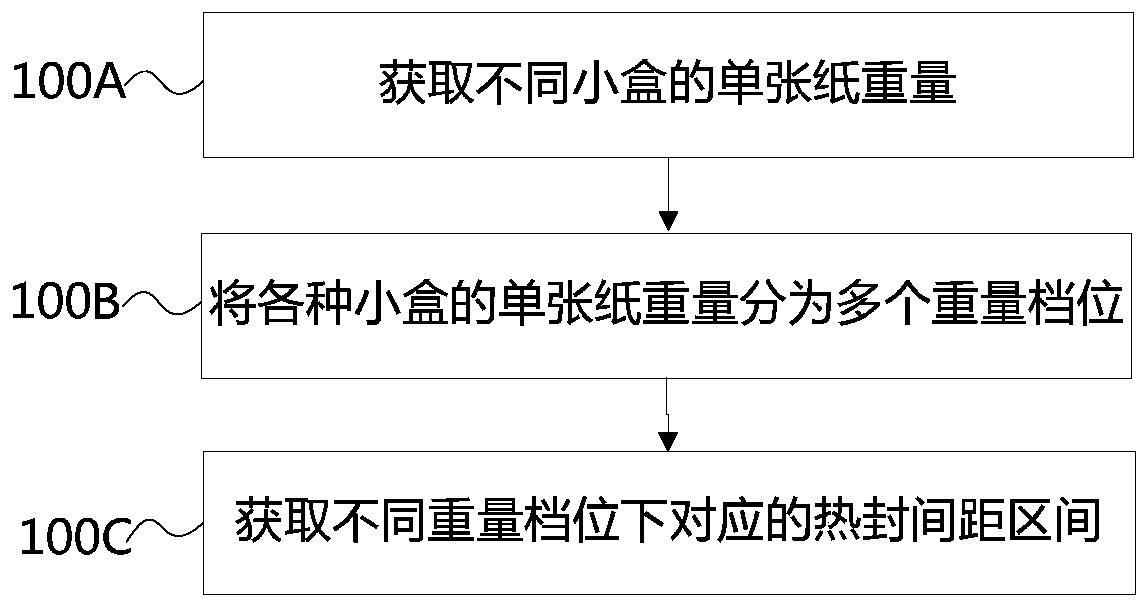

[0158] c. The grammage of the trademark leaflet in the small box is m2, and according to the comparison table of trademark single weight and heat-sealing distance, the heat-sealing distance is [87.2mm, 87.6mm].

[0159] (2) Set the initial heating temperature of the heat-sealing plate, and take the median T0 of the heat-sealing tempera...

Embodiment 2

[0169] After the equipment has been working for a period of time, it is necessary to detect and determine the effectiveness of the heat-sealing plate. It is known that the heat-sealing temperature range corresponding to the transparent paper material is [145°C, 155°C], and it is necessary to control the standard deviation S≤2.8 and the range R≤ 8.

[0170] (1) The equipment is powered on, and the initial heating temperature is set to T0 = 150°C;

[0171] (2) Detect the temperature of the heat-sealing plate with a thermal imager;

[0172] (3) Calculate the average value of the temperature at each location point 〒=147°C, standard deviation S=2.5, range R=5, S and R all meet the requirements;

[0173] (4) According to the deviation ΔT between T0 and 〒, correct the heat sealing setting temperature to be T0+ΔT before production.

Embodiment 3

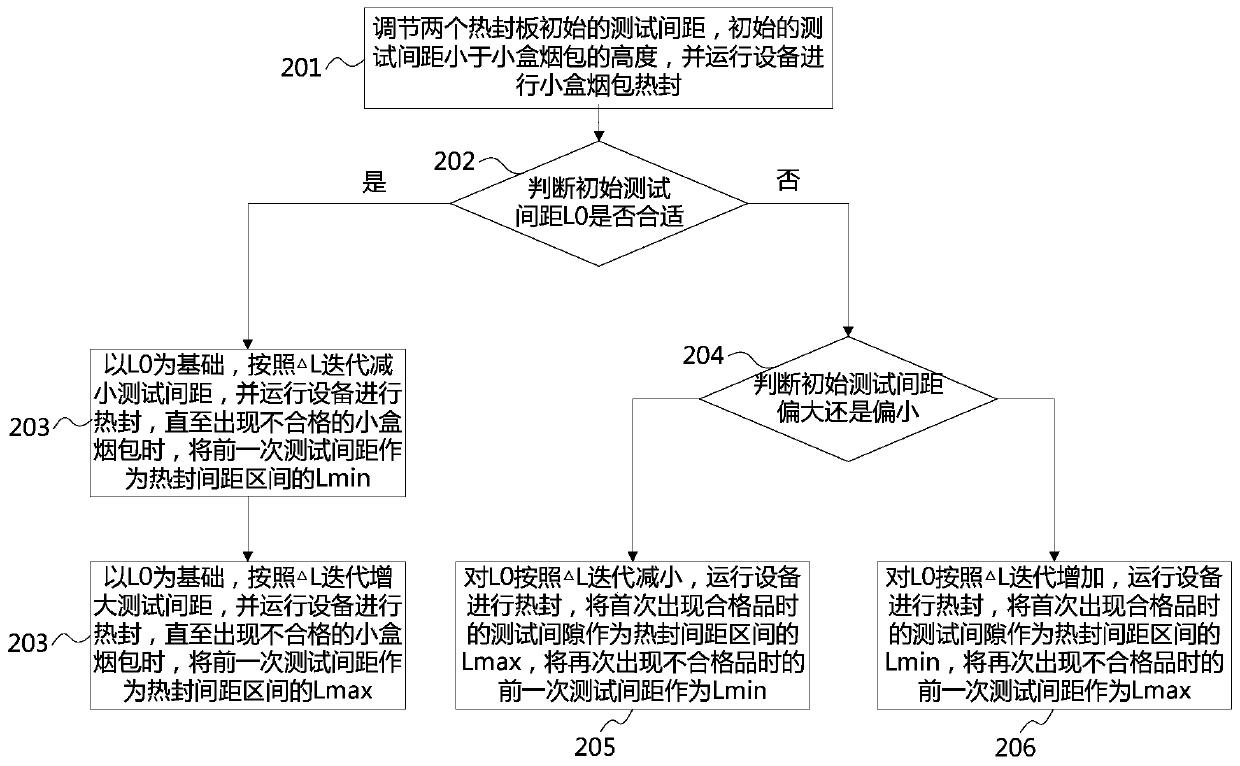

[0175] According to the comparison table between the weight of the small box sheet paper and the distance between the heat seals in the above table 2, select a certain brand product, and during the production process of changing the brand, conduct a verification test on the setting effect of the distance between the two heat seal plates, and select the heat seal of this brand. Any numerical value within the spacing interval is set as the initial heat-sealing spacing.

[0176] After the normal production of the product, in addition to the small packs that are fixedly rejected by the initial stage of the equipment, continuous sampling of 200 packs of small packs that normally flow into the subsequent process is carried out to test the sealing degree of the small packs and the appearance quality of the packaging, and the quality is qualified. The rate is 100%.

[0177] Compared with the previous production process of changing brands, the workshop often needs to repeatedly adjust ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com