Servo driver housing

A servo driver and housing technology, which is applied to sealed housings, electrical components, magnetic field/electric field shielding, etc., can solve the problems of complex molding process, not strong enough, poor anti-interference, etc., to improve stability and sealing, and ensure smooth Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

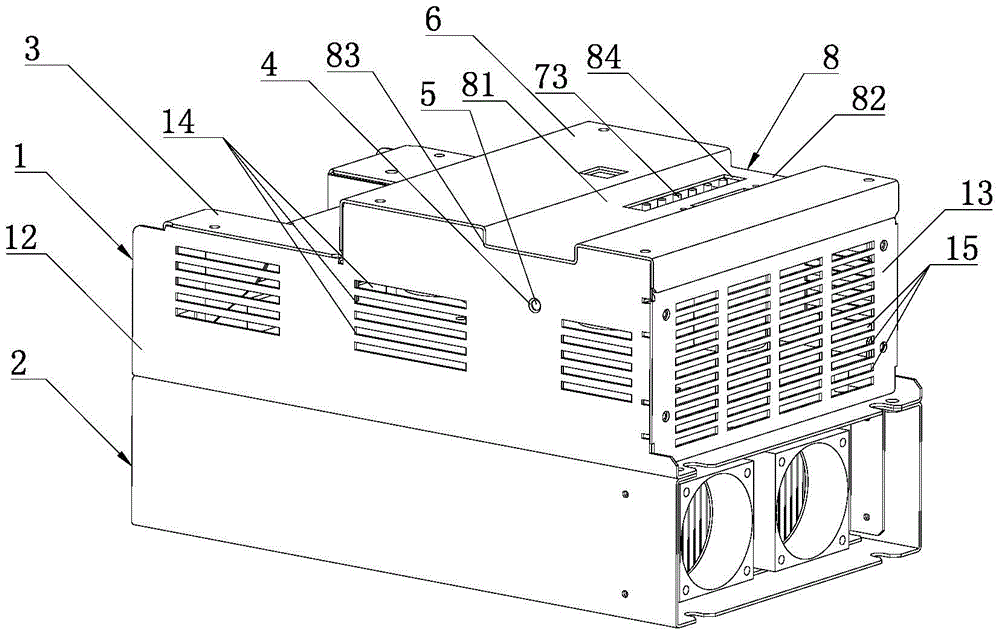

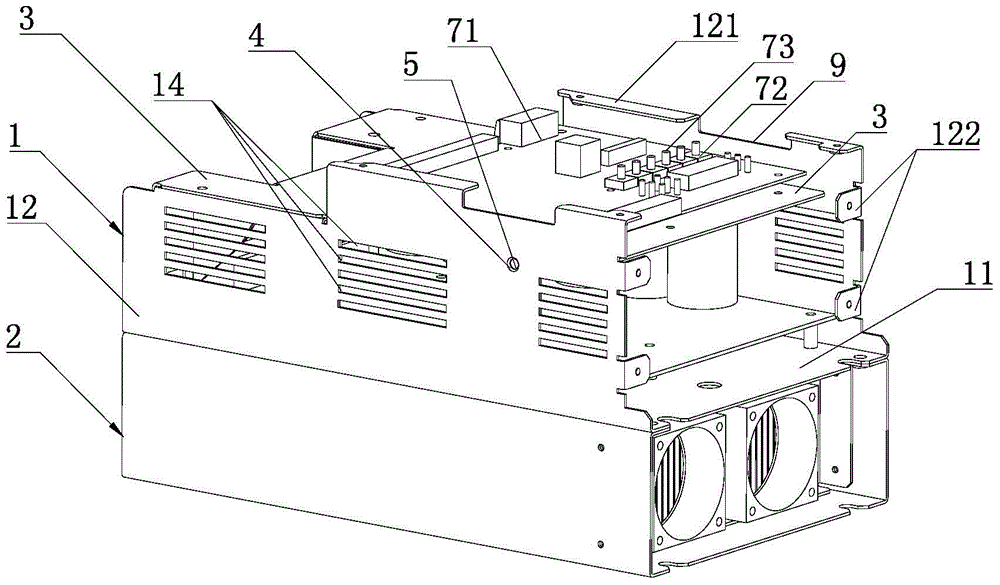

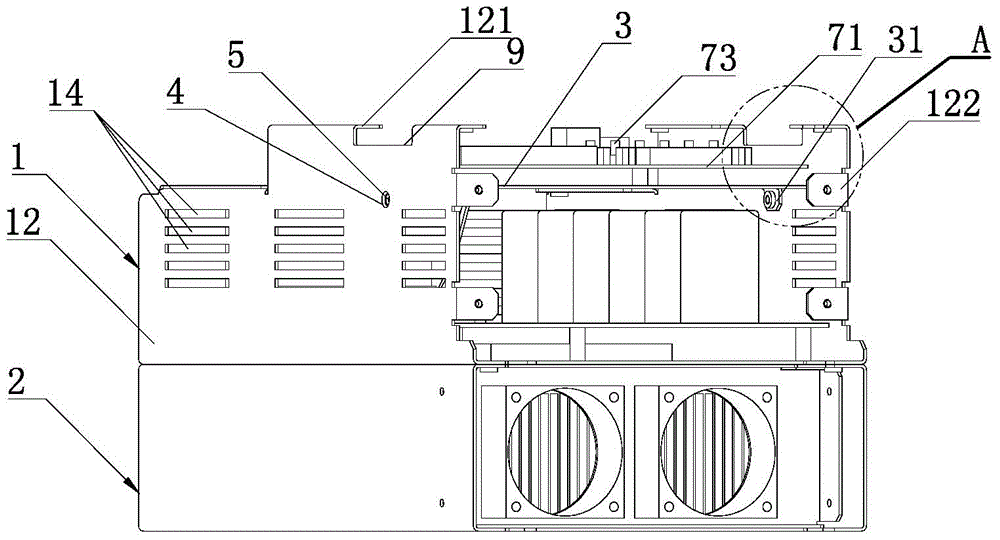

[0017] A servo drive housing proposed by the present invention, as shown in the figure, includes an upper box 1 and a lower box 2 that are made of aluminum-zinc-coated sheets and matched with each other. The bottom plate 11 is parallel to the shielding plate 3 that is close to the inner wall of the two side plates 12 symmetrical to the upper box body 1. In this embodiment, the shielding plate 3 is partly located in the upper box body 1, and partly located on both sides of the upper box body 1. The top of the side plate 12; the symmetrical side edges of the shielding plate 3 extend vertically downwards respectively, and a first connecting piece 31 with a screw hole parallel to the two side plates 12 of the upper box body 1 is provided, and is located on the shielding plate 3. The first connecting pieces 31 on both sides of the plate 3 are symme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com