Self-cleaning type polypropylene recycle gas compressor gas film sealing structure

A technology of air film sealing and polypropylene, which is applied in the direction of engine sealing, mechanical equipment, engine components, etc., can solve the problems of unreliable structure, high maintenance cost, high price, etc., and achieve short service life and improve sealing stability performance, installation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

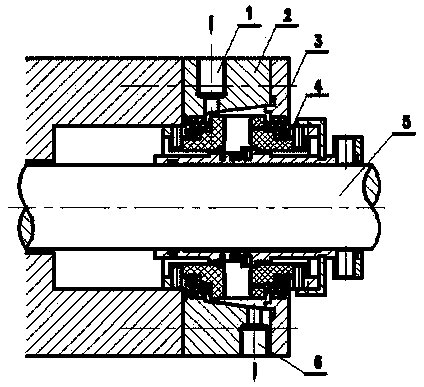

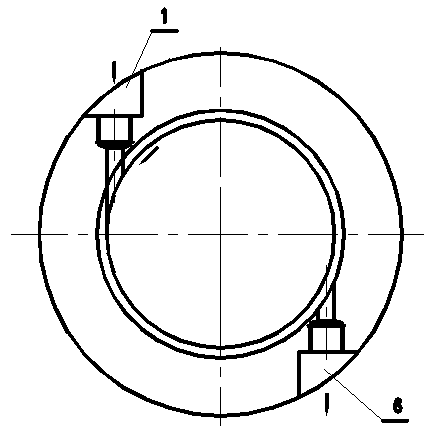

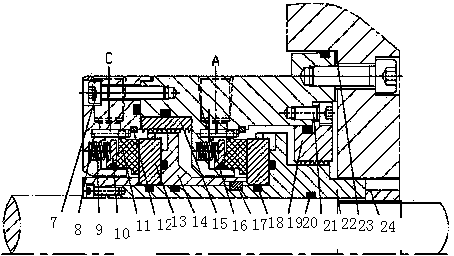

[0014] Such as figure 1 As shown, the self-cleaning mechanical seal cavity structure of the present invention is composed of a machine washing liquid inlet 1, a body vertebral body 2, a structural gland 3, an air film sealing device 4, a shaft 5 and a washing liquid outlet 6, and is characterized in that: The mechanical sealing device 4 is installed on the shaft 5 , and is integrally sleeved in the vertebral body 2 of the body, and fixed on the vertebral body 2 of the body through the structural gland 3 . Wherein the sealing cavity of the vertebral body 2 of the body is processed into a vertebral body structure, the inside diameter of the sealing cavity is small, and the outside diameter is large, forming a truncated cone structure. The lotion inlet 1 tangentially enters the inner outer diameter of the vertebral body 2 of the body, and its tangential direction is consistent with the rotation direction of the mechanical seal dynamic ring. The washing liquid outlet 6 is tangent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com