Novel dynamic pressure damping sealing structure

A sealing structure and damping technology, which is applied in the direction of engine sealing, engine components, mechanical equipment, etc., can solve the problems of unfavorable rotor bearing system stability, poor sealing ability of screw seal, large circumferential fluid excitation force, etc., to achieve increased Large roughness and damping coefficient, improve the sealing ability and the effect of improving the sealing damping coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings. The following implementations are only used to illustrate the technical solutions of the present invention more clearly, but not to limit the protection scope of the present invention.

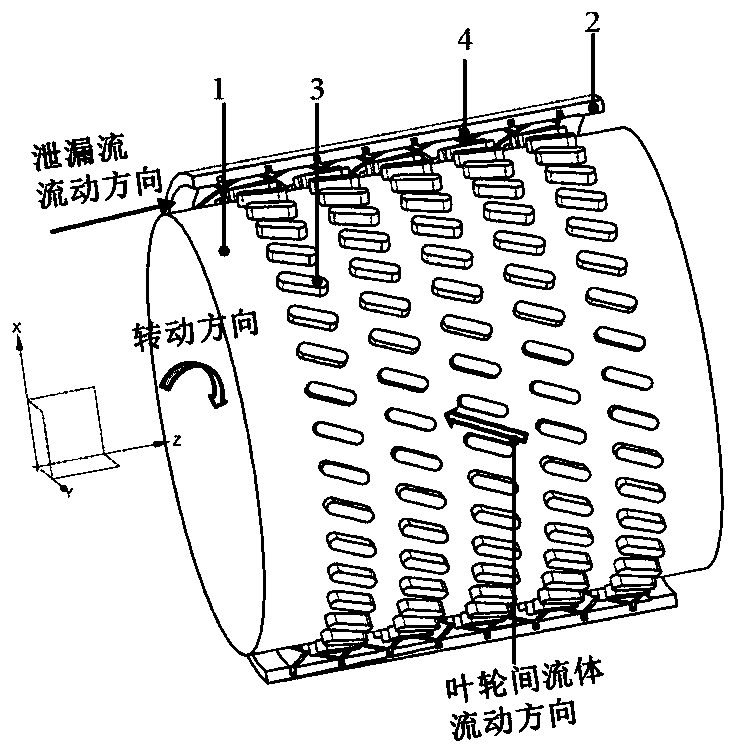

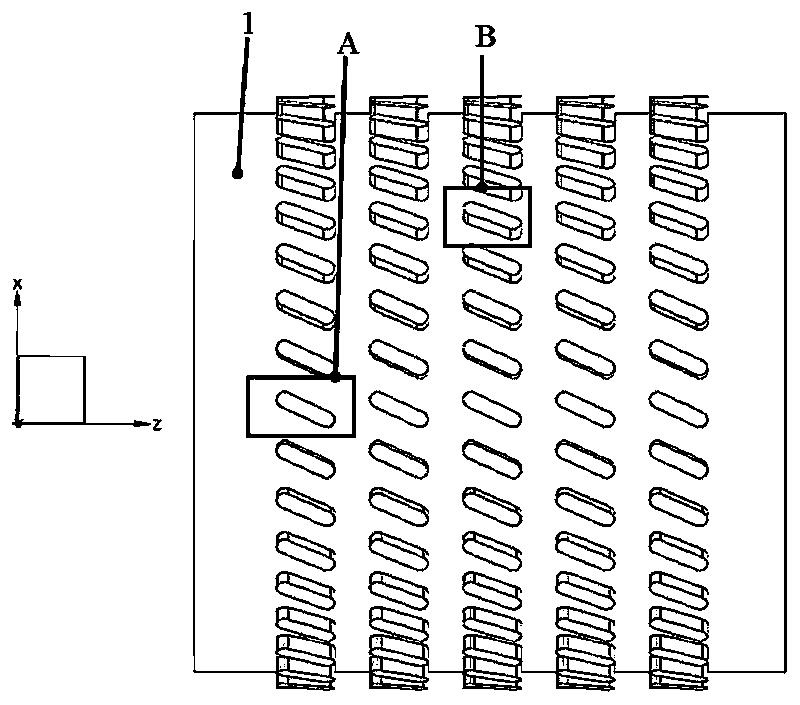

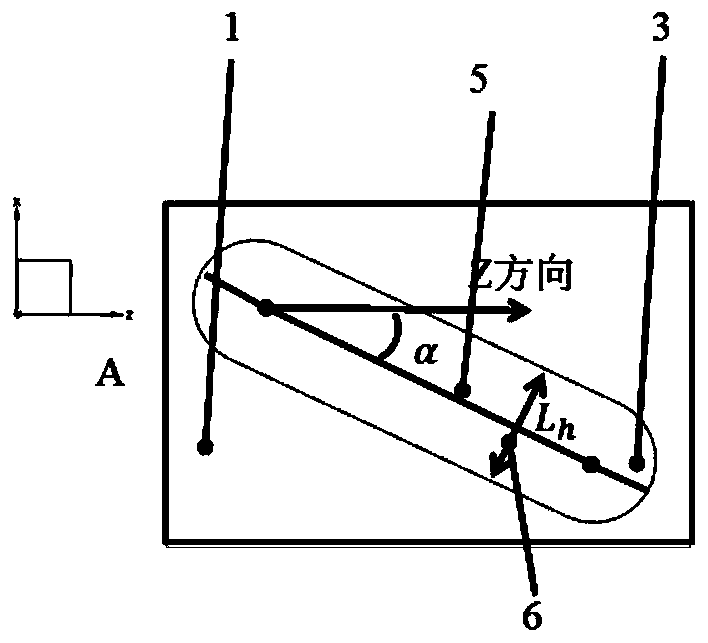

[0029] see Figure 1 to Figure 6 , a new type of dynamic pressure damping seal structure provided by the present invention, including a sealed rotor part 1, and a sealed stator part 2 that is sleeved outside the sealed rotor part 1 and used in conjunction with it; wherein, there are several The micro-impeller 3 capable of generating a dynamic pressure pumping effect, the inner surface of the sealed stator part 2 is provided with a textured structure 4 capable of inhibiting the development of circumferential swirl and increasing the damping coefficient.

[0030] Further, the micro-impellers 3 arranged on the surface of the sealed rotor part 1 are all inclined towards the rotati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com