Custom-pressure expandable naked eye packer

A packer and open-hole technology, applied in sealing/packing, wellbore/well components, earth-moving drilling, etc., can solve the problems of unreliable setting, failure of the rubber tube to burst the seat, and failure of the seat, etc. Achieve the effect of improving sealing stability, reducing costs, and protecting rubber cartridges

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

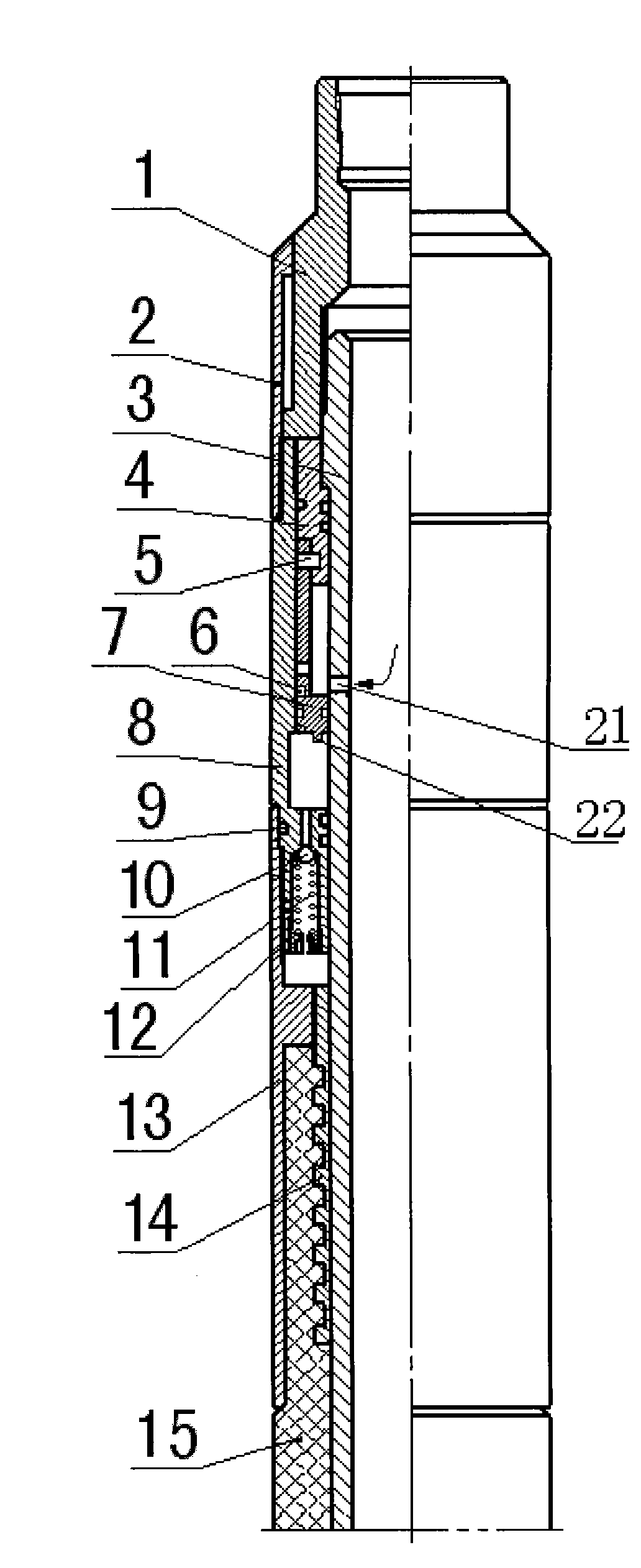

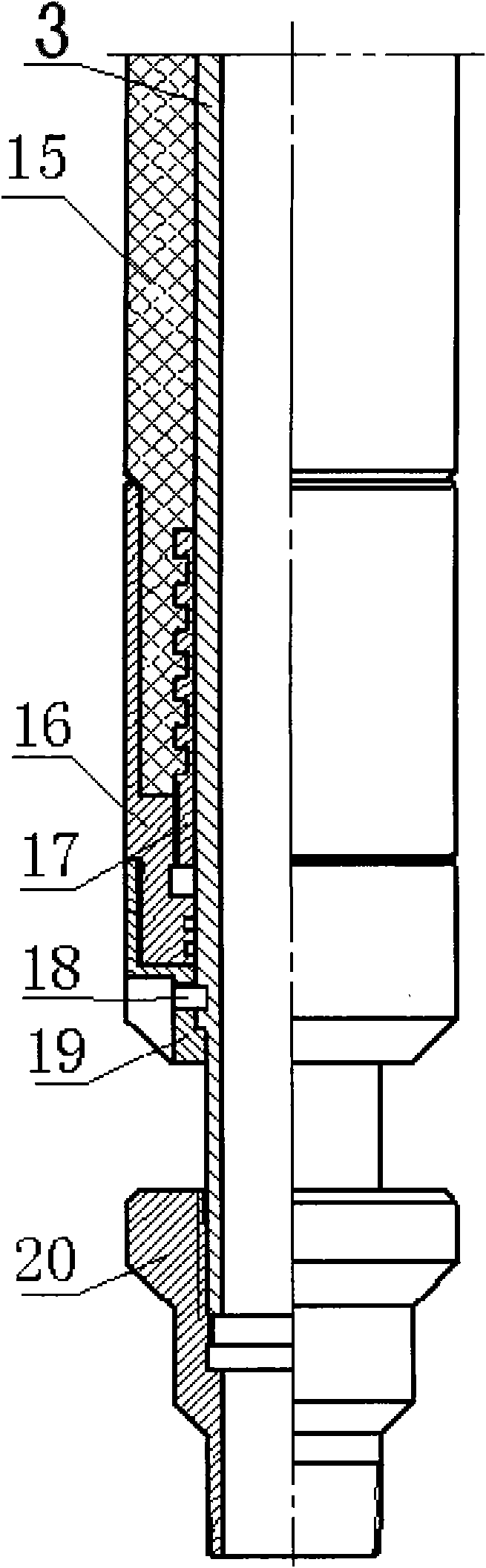

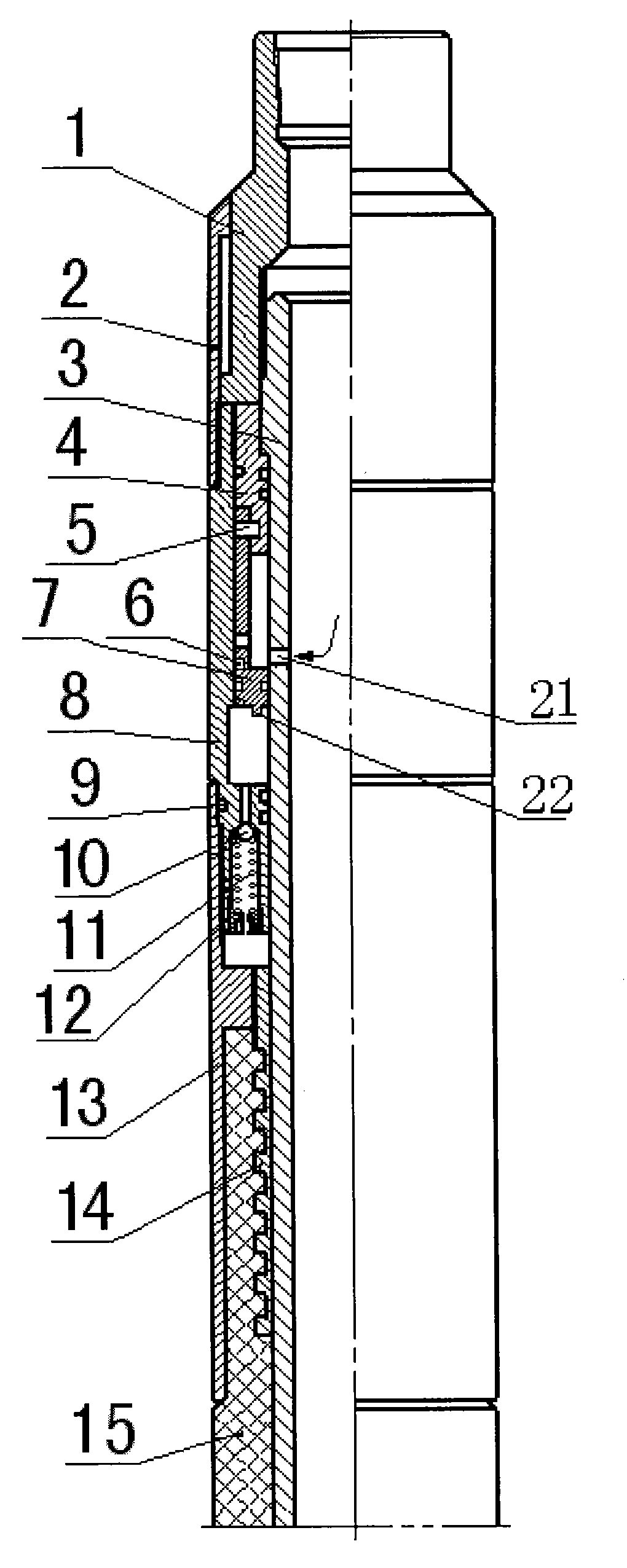

[0020] Embodiment 1: Taking a self-regulating pressure expansion type open hole packer applied to an open hole with a diameter of 152.4mm as an example, the present invention will be further described in detail.

[0021] refer to figure 1 . The self-setting pressure expanding open hole packer is mainly composed of an upper joint 1, a setting mechanism, a sealing mechanism, an unsealing mechanism, a center pipe 3 and a lower joint 20. There is an internal thread at the lower end of the upper joint 1, and the inner thread at the lower end of the upper joint 1 is connected with a central pipe 3; the lower end of the central pipe 3 is threaded with a lower joint 20. A sealing mechanism is sleeved on the central tube 3 . The inner diameter of the center pipe 3 is 60mm.

[0022] The sealing mechanism is mainly composed of an upper pressing cap 13 , an upper connecting body 14 , a rubber tube 15 , a lower pressing cap 16 and a lower connecting body 17 . The outer diameter of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com