Small-diameter well cementing packer

A small-diameter, packer technology, which is applied in sealing/isolation, wellbore/well components, earthwork drilling and production, etc., can solve problems affecting later production, leakage and blockage of screen pipes, etc., to reduce the probability of cement leakage, Strong sealing ability and small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

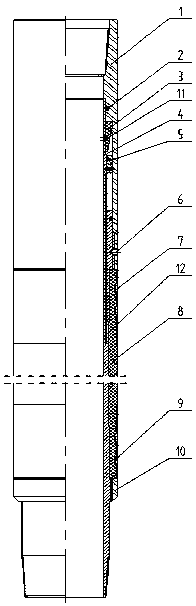

[0017] combined with figure 1 , this embodiment mainly consists of an upper joint 1, a seal 2, a liquid inlet sealing ring 3, a central tube 4, an opening ring 5, a pin 6, an upper fixing sleeve 7, a rubber tube 8, a lower fixing sleeve 9, and a locking ring 10 Composition, a liquid inlet hole 11 is opened on the central tube 4, and a tool cavity 12 (equivalent to a diversion groove or a diversion channel) is formed between the central tube 4 and the rubber cartridge 8.

[0018] Among them: the upper joint 1 is threaded, which mainly serves the function of connecting the upper tool. The upper joint 1 and the central pipe 4 are fixed by the pin 6 before (it can also be fixed by threading the top of the central pipe), and the connection between the upper joint 1 and the central pipe 4 The gap is sealed by the seal 2, the upper part of the center pipe 4 has a radial liquid inlet hole 11, the liquid inlet seal ring 3 is located on the liquid inlet hole 11 of the center pipe 4, and...

Embodiment 2

[0025] Refer to attached figure 1 , a small-diameter cementing packer, including a pipe string composed of an upper joint 1 and a central pipe 4, and an upper fixed sleeve 7, a rubber sleeve 8, a lower fixed sleeve 9, and a locking ring arranged on the outer wall of the pipe string 10, wherein: after the upper joint 1 is sealed and connected to the top of the central pipe 4, the lower part of the upper joint 1 and the upper part of the central pipe 4 form an annular cavity; the upper part of the upper fixing sleeve 7 and the lower end of the upper joint 1 and the central pipe 4 pass through The pin 6 is fixedly connected, and the lower fixing sleeve 9 is axially locked and positioned by the locking ring 10 threadedly connected with the lower part of the central tube. Clamped outside the central tube 4; a radial through hole is provided on the central tube 4 in the upper section of the annular cavity, and the radial through hole is provided with a one-way valve (replacing the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com