Fuel cell bipolar metal plate with enhanced sealing property

A metal bipolar plate and fuel cell technology, applied in the direction of battery electrodes, circuits, electrical components, etc., can solve the problems of sealing effect, affecting stack matching and alignment, and high cost, so as to improve sealing stability and improve overall Strength and the effect of improving the life of the stack

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with drawings and embodiments.

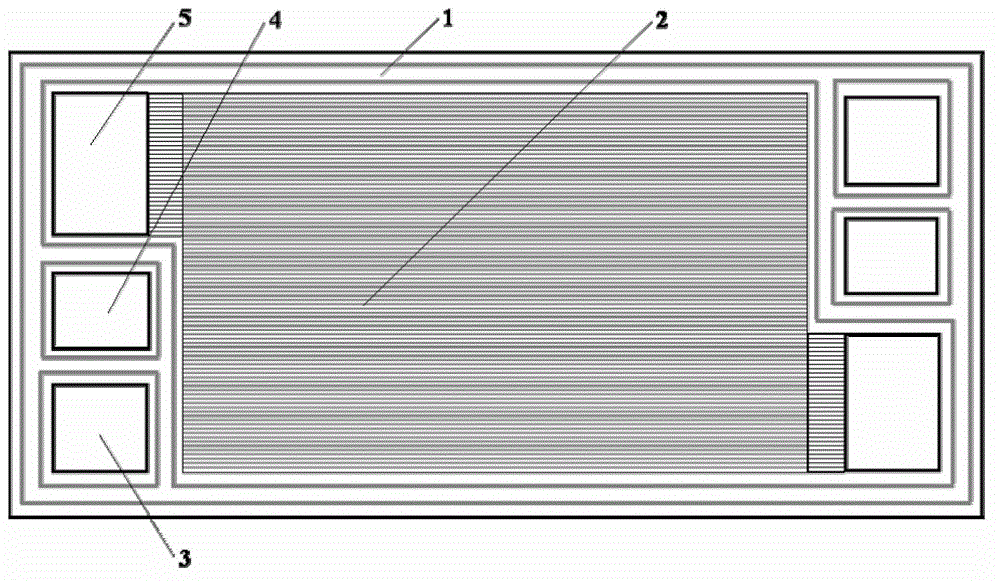

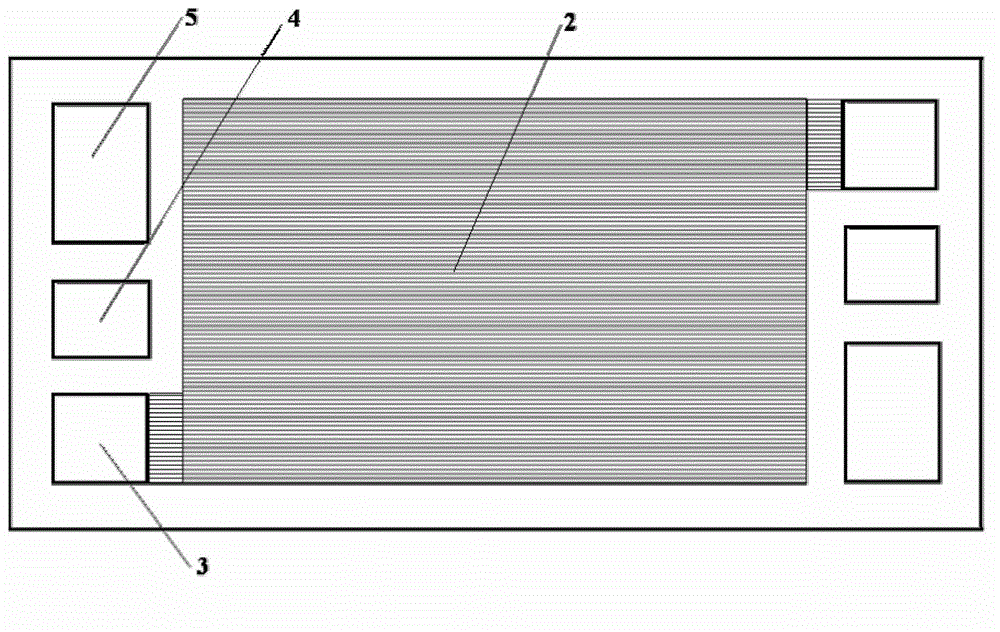

[0020] Fuel cell metal bipolar plates with enhanced sealing performance, including oxygen pole plates and hydrogen pole plates, the oxygen pole plates and hydrogen pole plates are provided with flow channels 2, common hydrogen channel openings 3, common air channel openings 5, and common cooling water channels The opening 4 and the sealant wire frame, the sealant wire frame is arranged along both sides of the flow channel and around the common hydrogen channel opening 3, the common air channel opening 5 and the common cooling water channel opening 4, and the oxygen glue wire frame 1 on the oxygen plate and The oxygen plate has an integrated structure, that is, the oxygen glue wire frame 1 is molded together with the flow channel and the common channel opening on the oxygen plate; the hydrogen glue wire frame 6 on the hydrogen plate is a separate structure from the hydrog...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com