Patents

Literature

45results about How to "Improve fuel injection efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

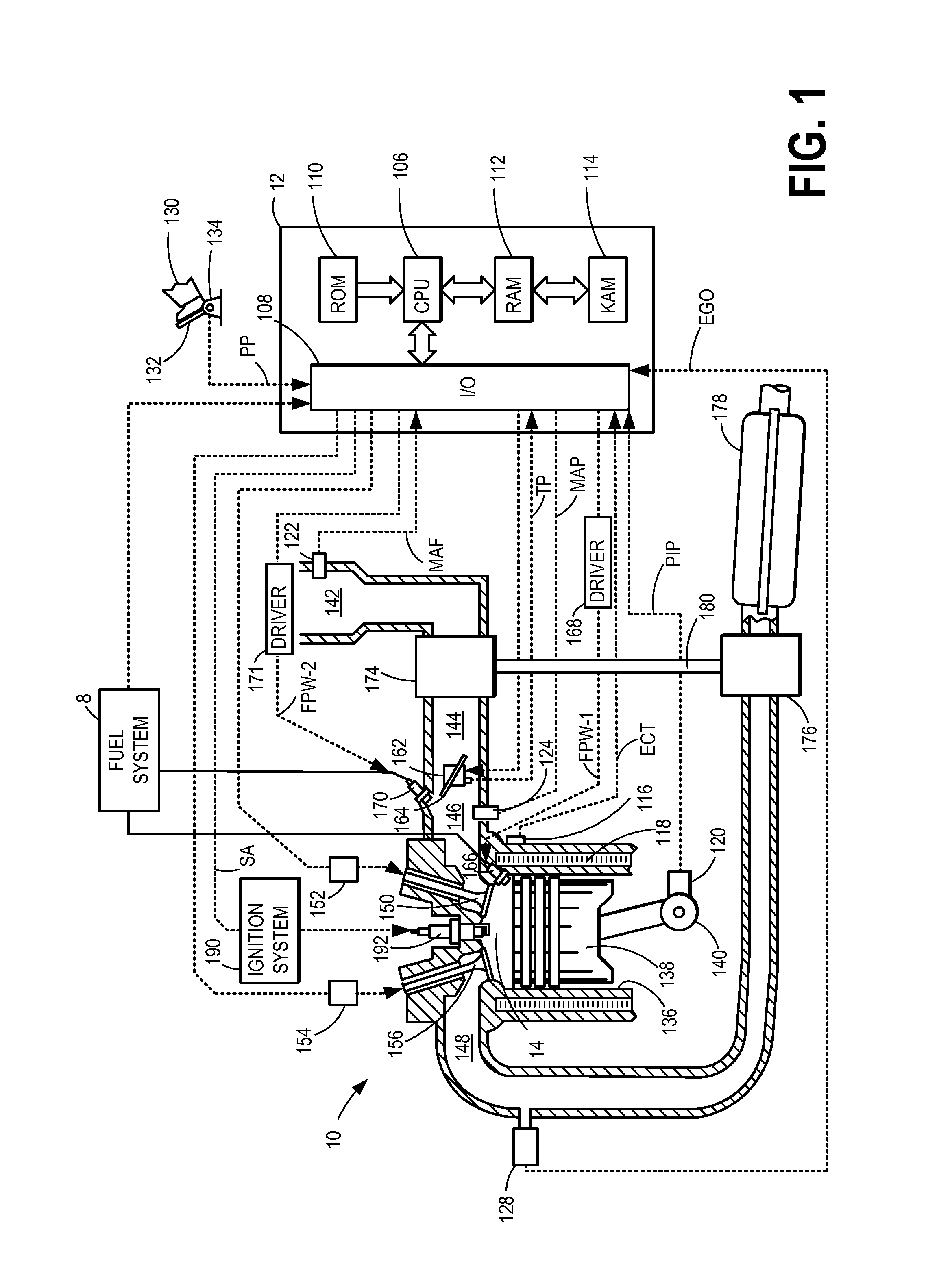

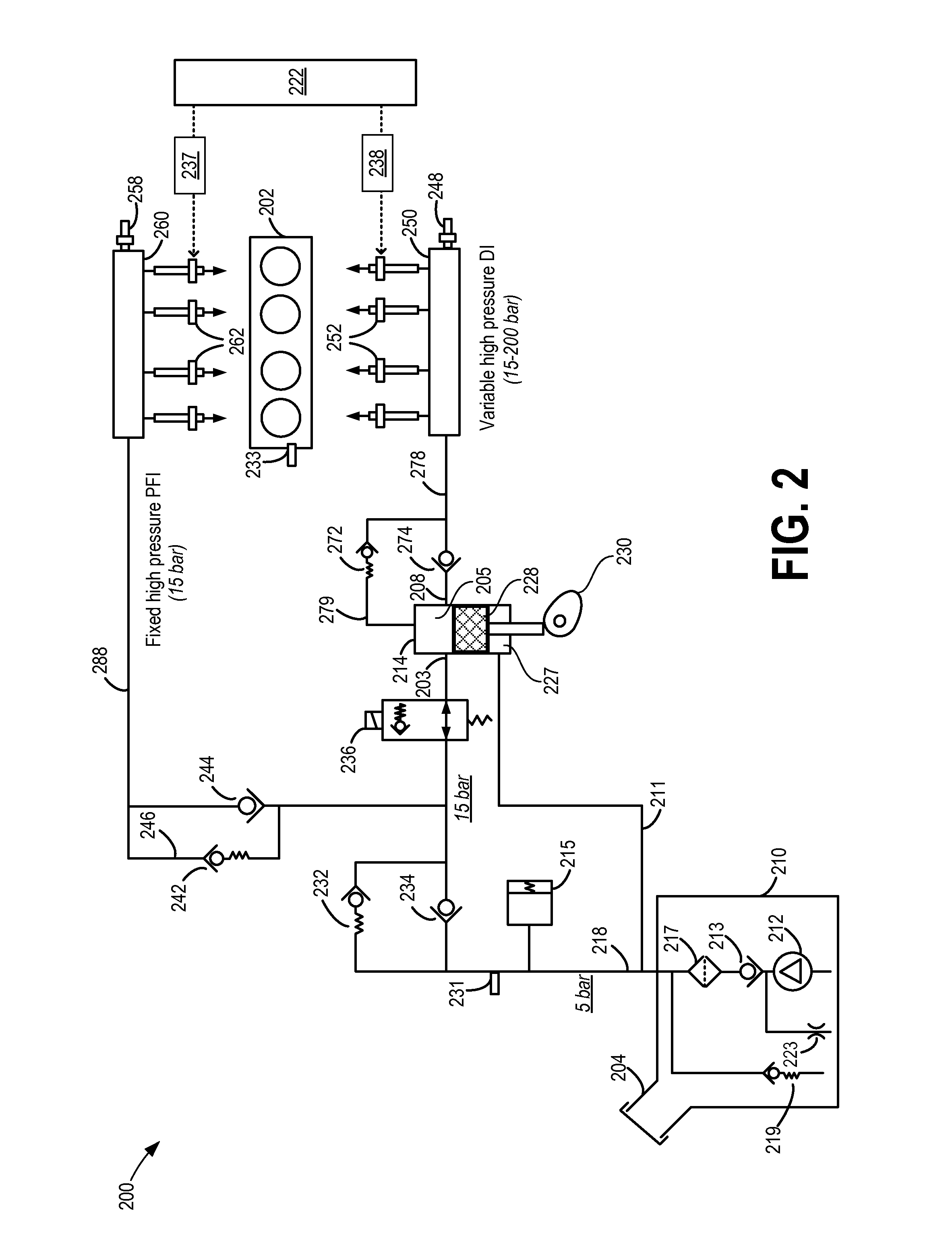

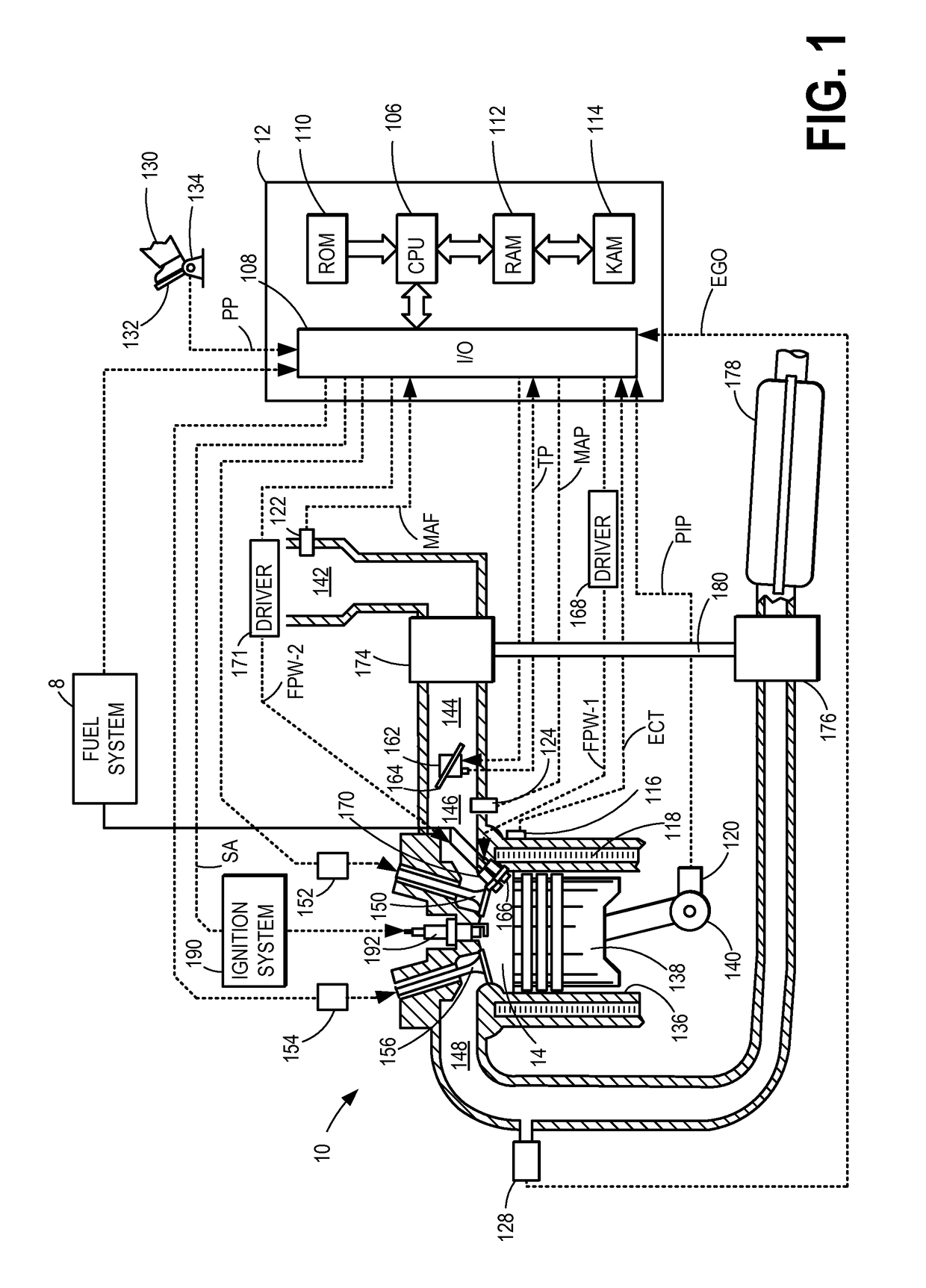

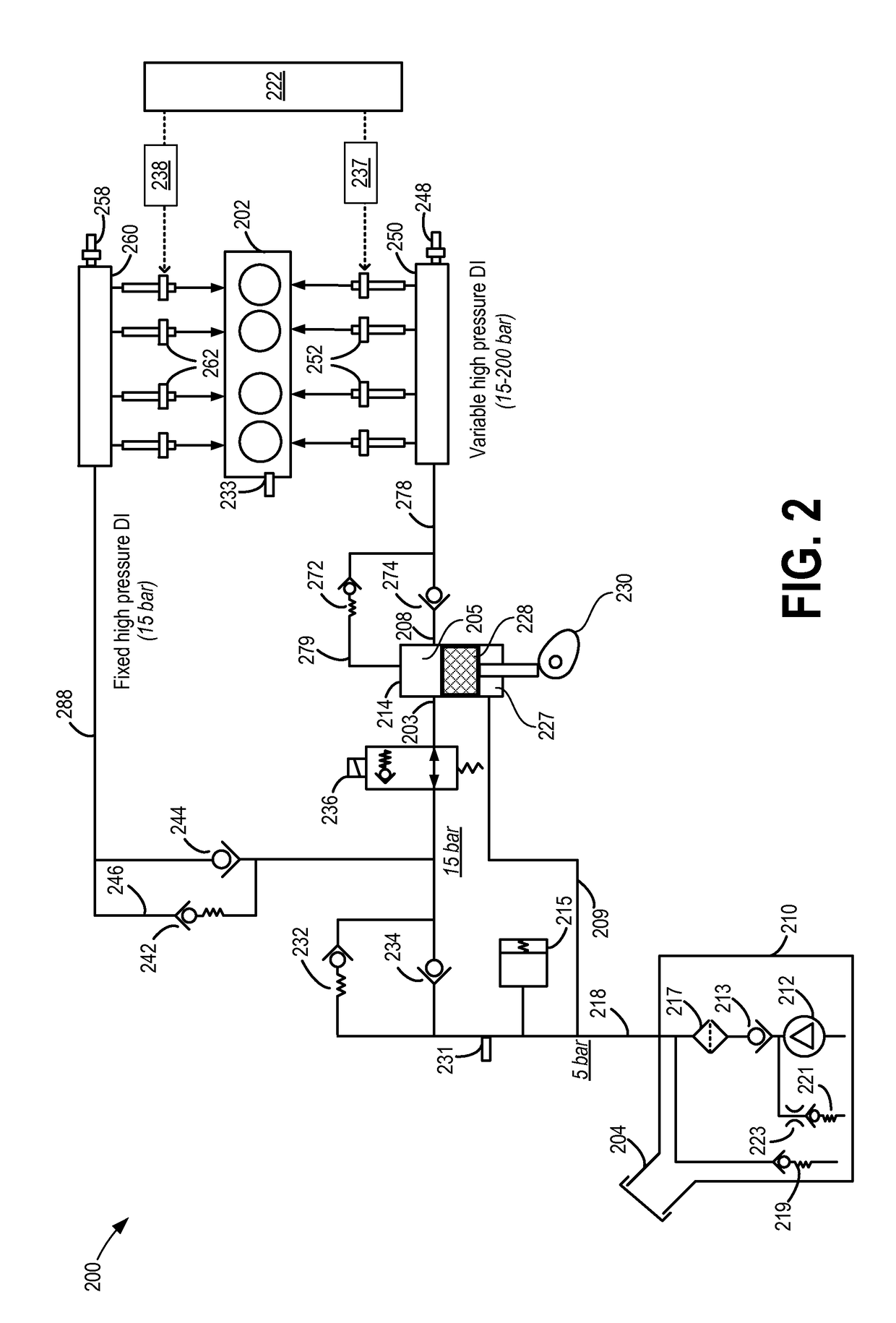

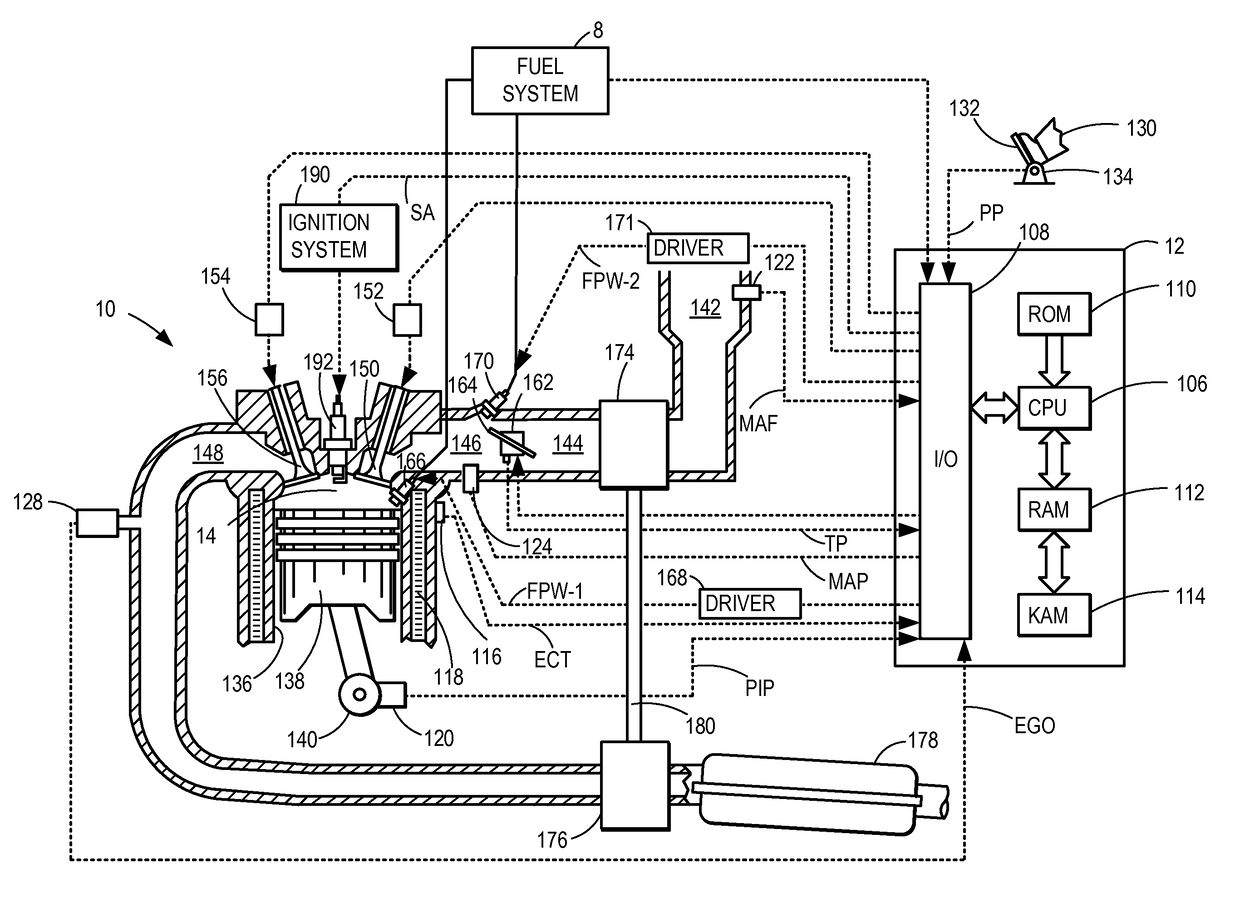

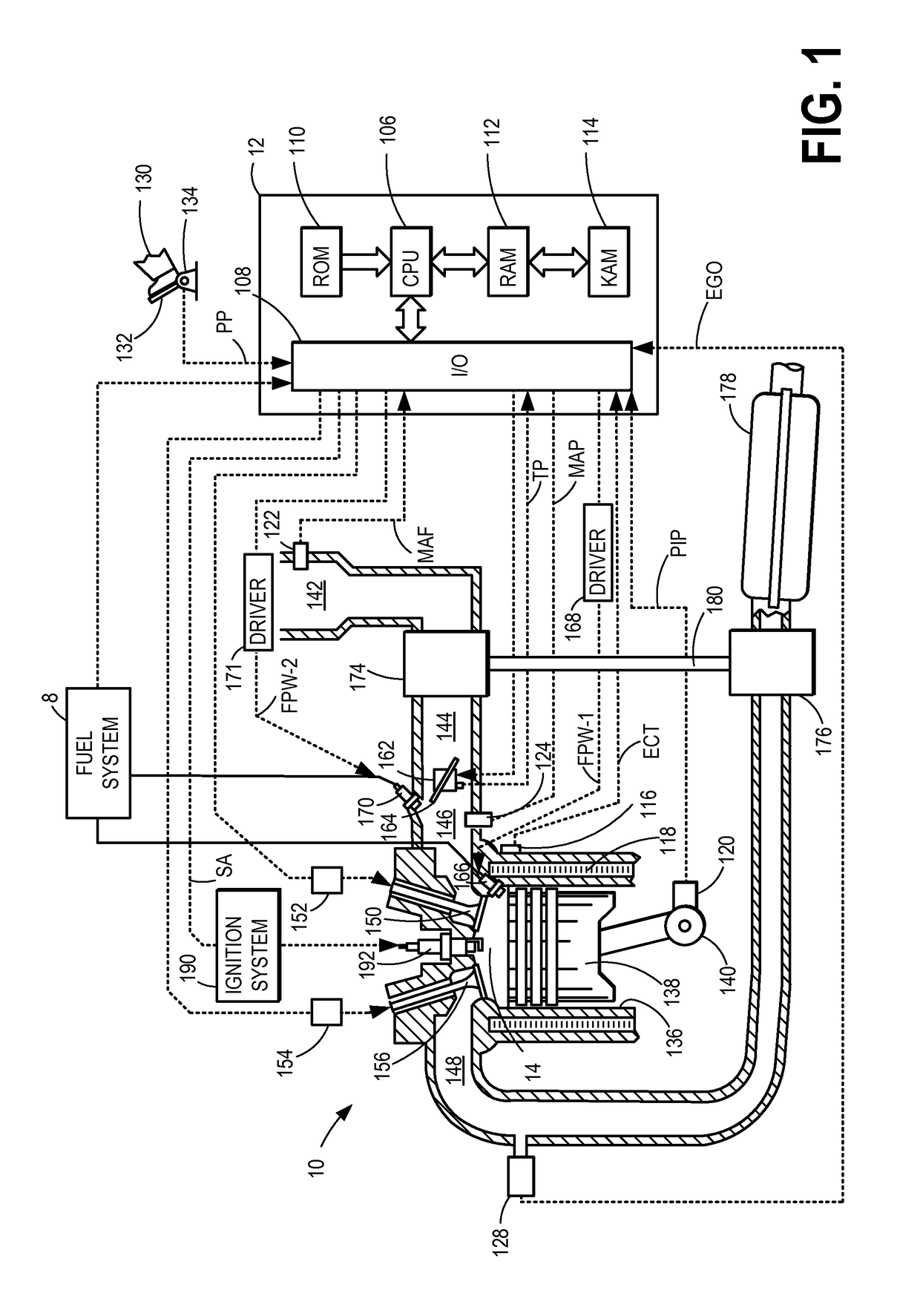

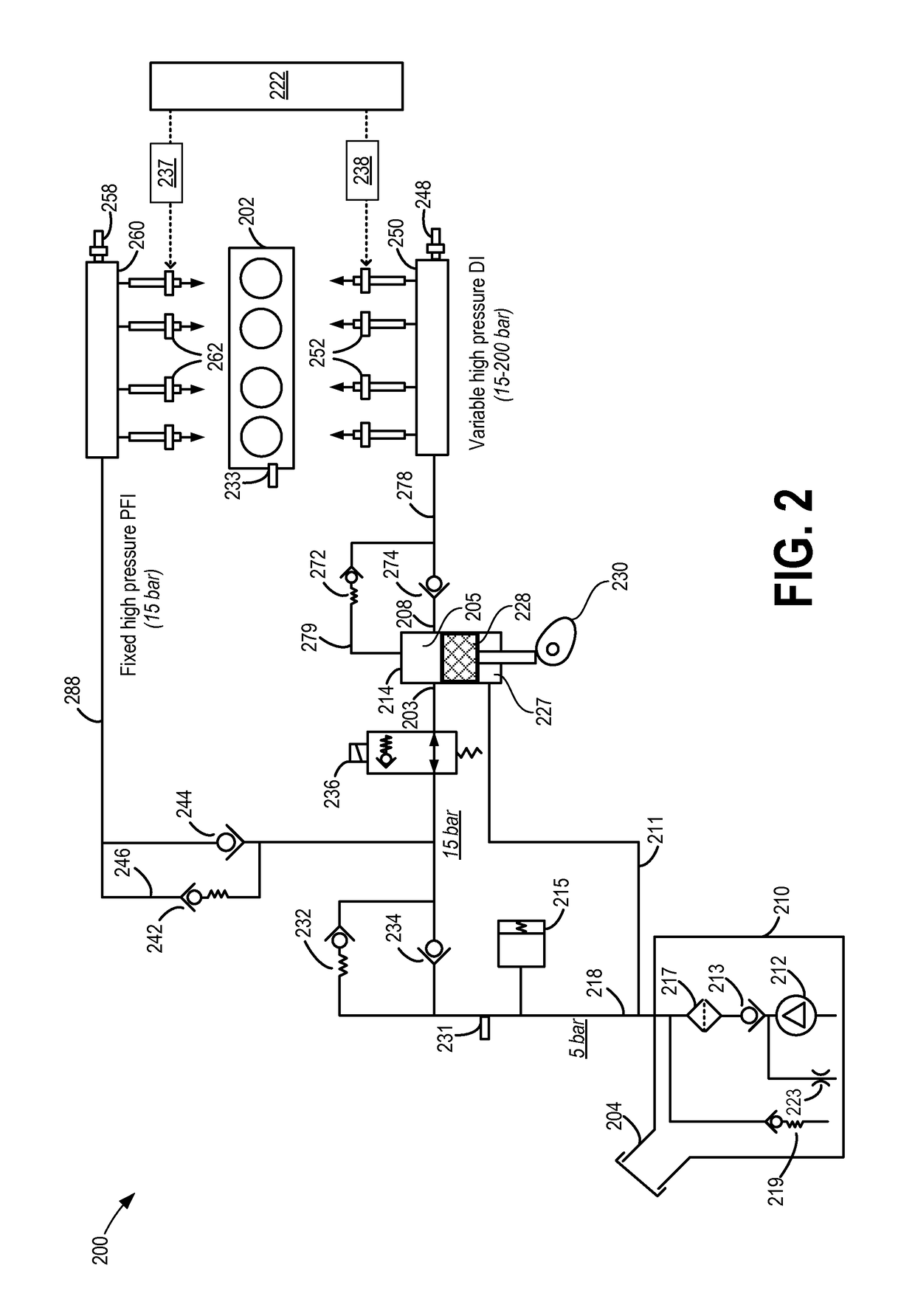

Methods and systems for fixed and variable pressure fuel injection

ActiveUS20160169147A1Improve cylinder charge coolingIncrease the compression ratioElectrical controlInternal combustion piston enginesRail pressureSystem configuration

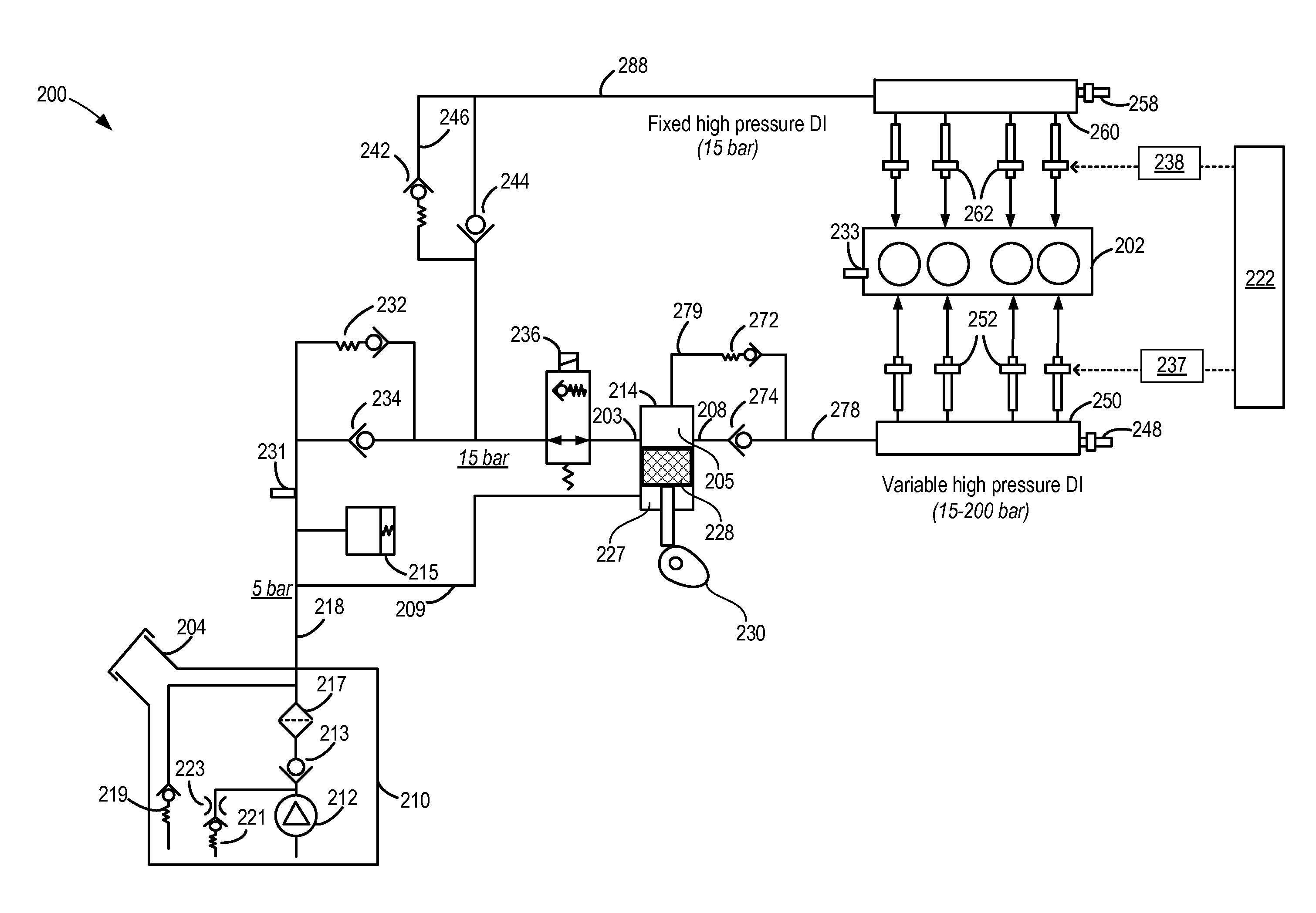

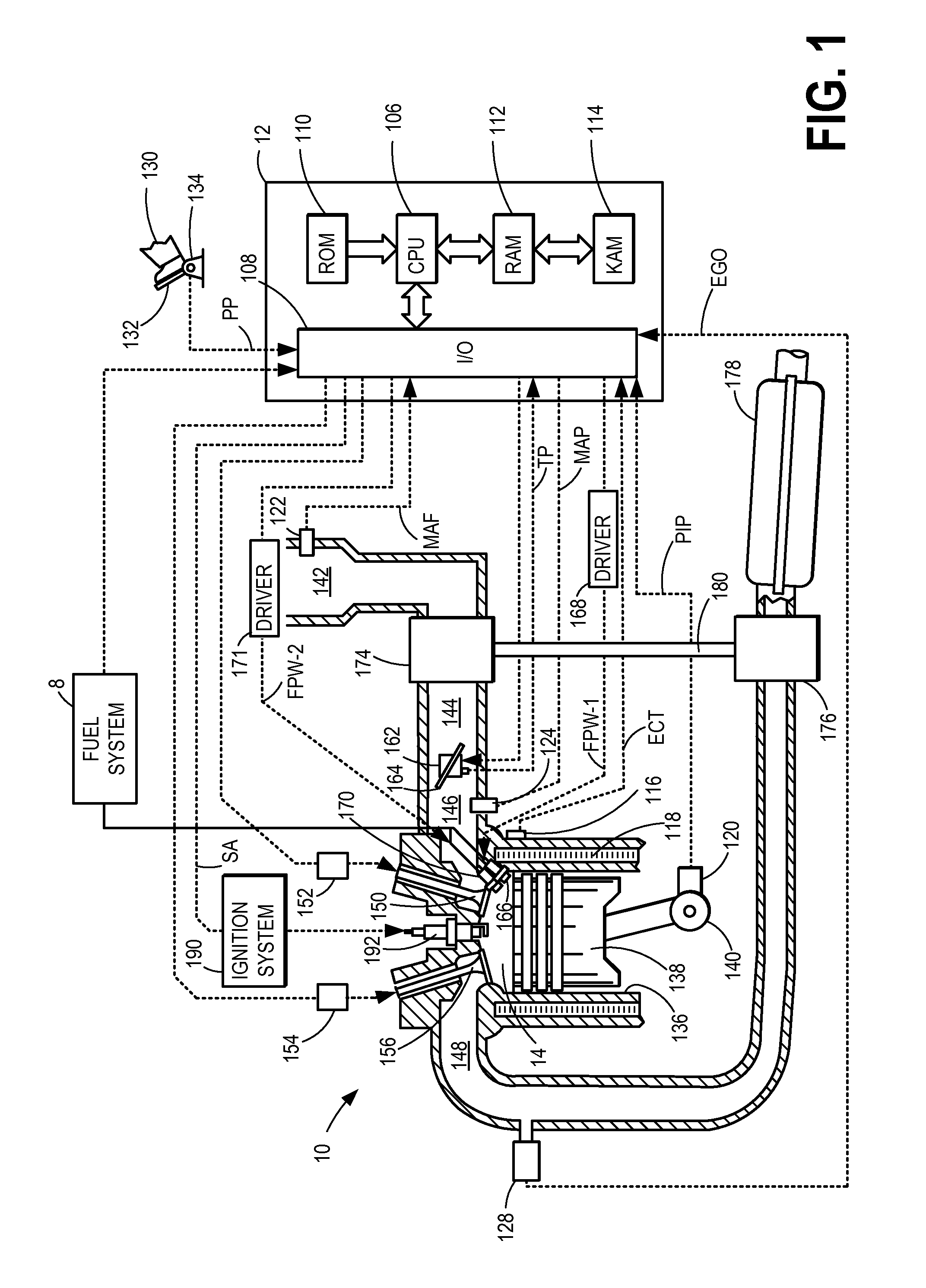

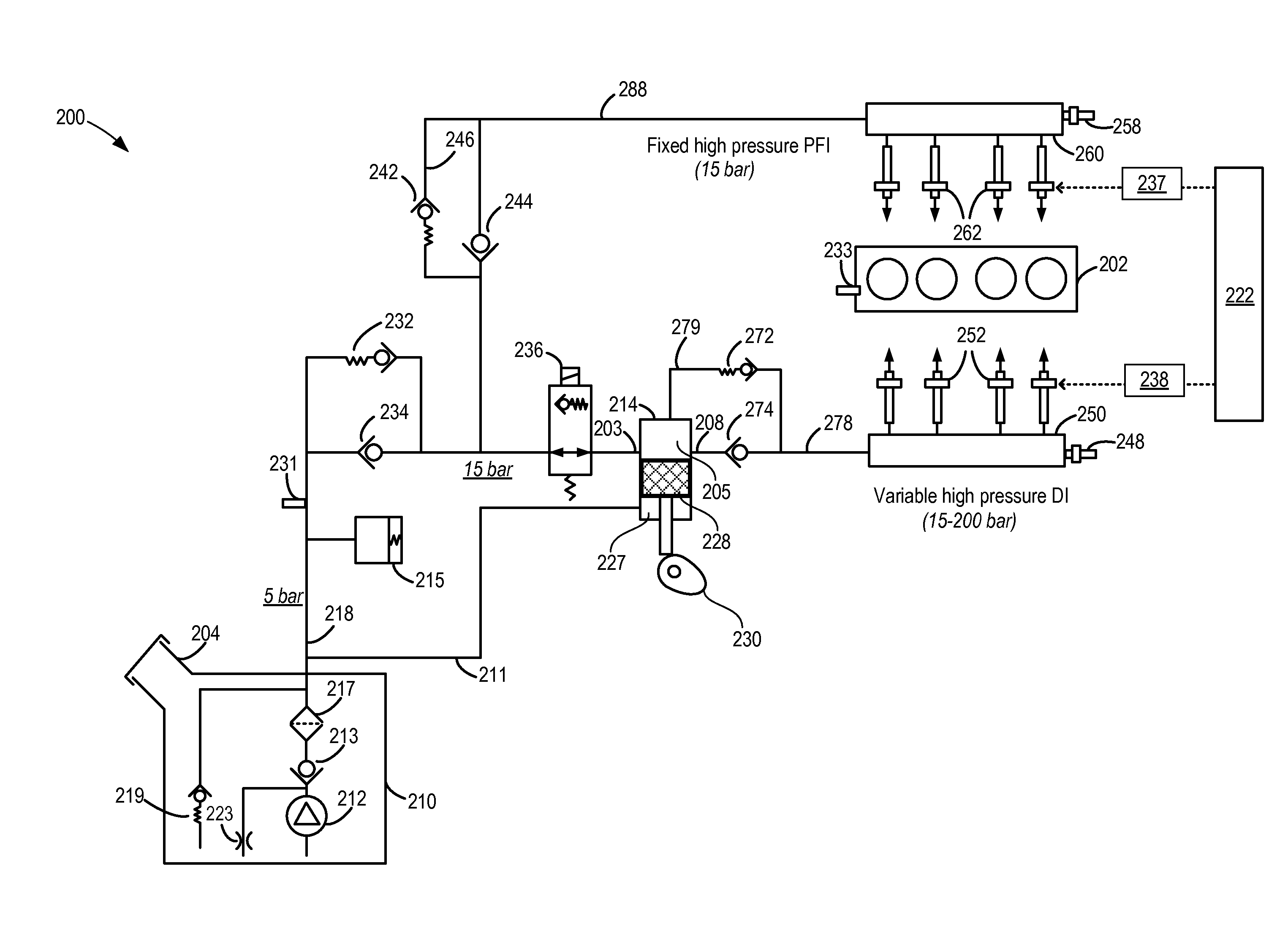

Methods and systems are provided for operating a high pressure injection pump to provide each of high fixed fuel pressure at a first direct injection fuel rail and high variable fuel pressure at a second direct injection fuel rail. The direct injection fuel rail pressure can be raised above a pressure provided with a lift pump via a fuel system configuration that includes various check valves, pressure relief valves, and a spill valve positioned between an inlet of the high pressure injection pump and the port injection fuel rail. Fixed and variable high pressure direct injection may be advantageously used to provide learn the ballistic region of each direct injector.

Owner:FORD GLOBAL TECH LLC

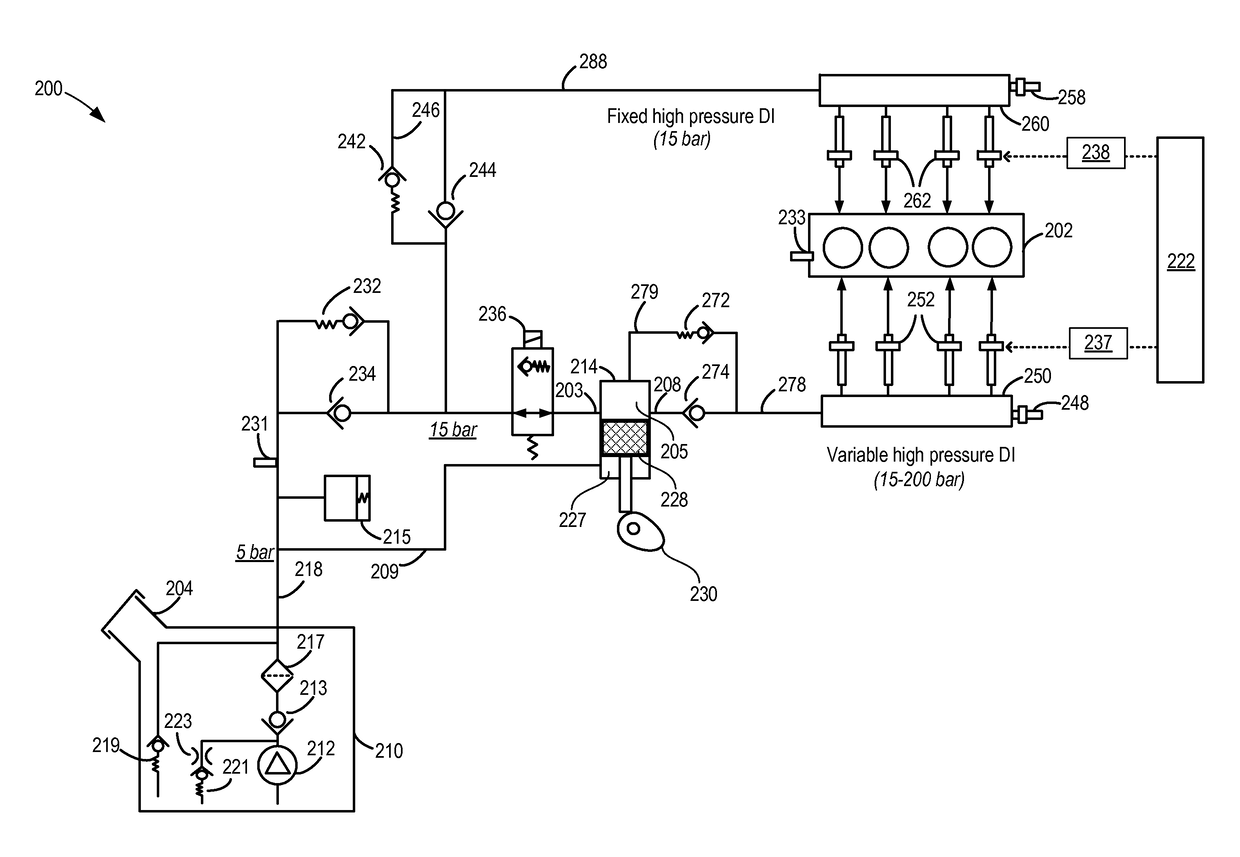

Methods and systems for fixed and variable pressure fuel injection

ActiveUS20160169144A1Improve cylinder charge coolingIncrease the compression ratioElectrical controlFuel-injection pumpsRail pressureInjection pump

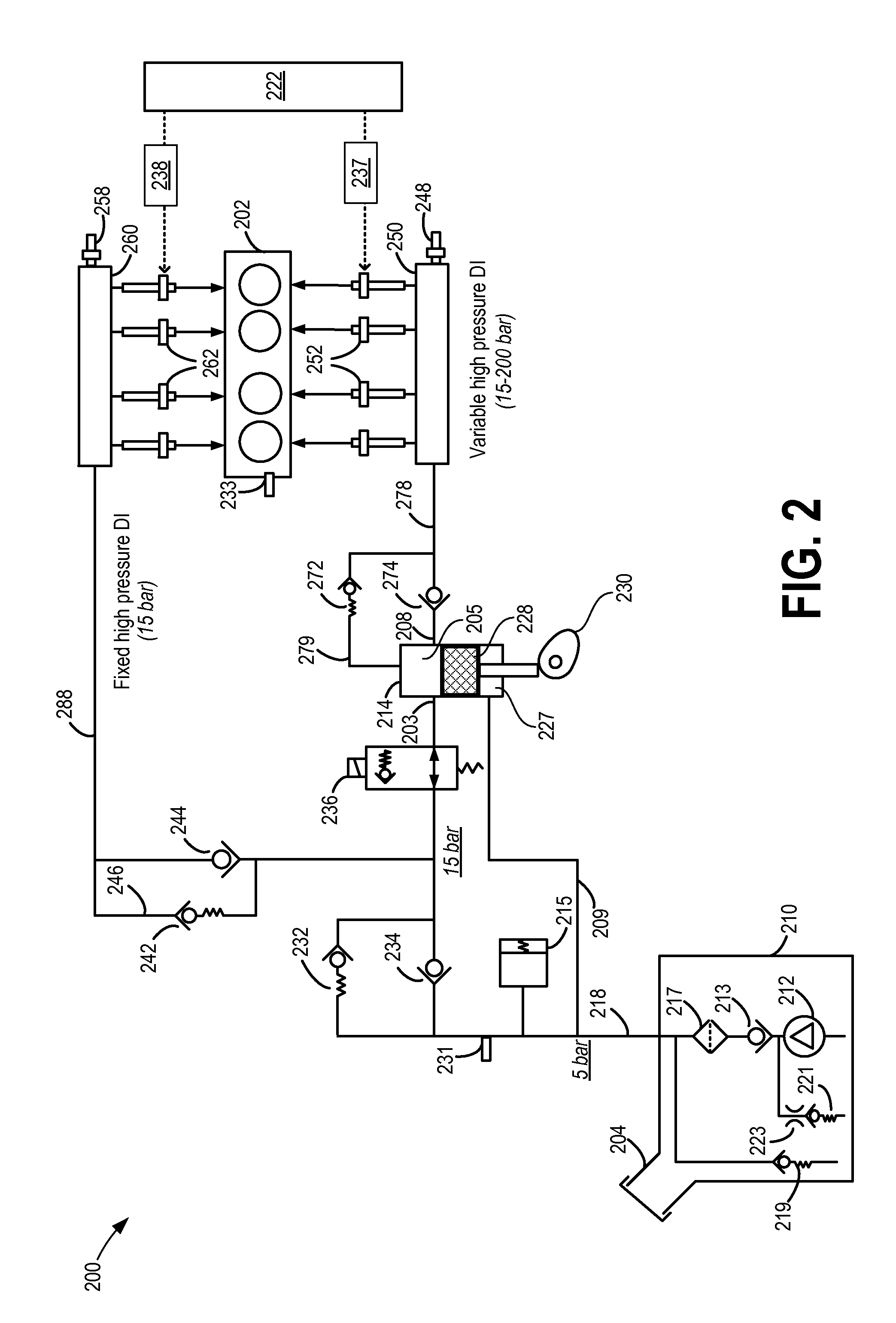

Methods and systems are provided for operating a high pressure injection pump to provide each of high fixed fuel pressure at a port injection fuel rail and high variable fuel pressure at a direct injection fuel rail. Port injection fuel rail pressure can be raised above a pressure provided with a lift pump via a fuel system configuration that includes various check valves, pressure relief valves, and a spill valve positioned between an inlet of the high pressure injection pump and the port injection fuel rail. High pressure port injection may be advantageously used to provide fuel at high pressure during conditions when fuel delivery via high pressure direct injection is limited.

Owner:FORD GLOBAL TECH LLC

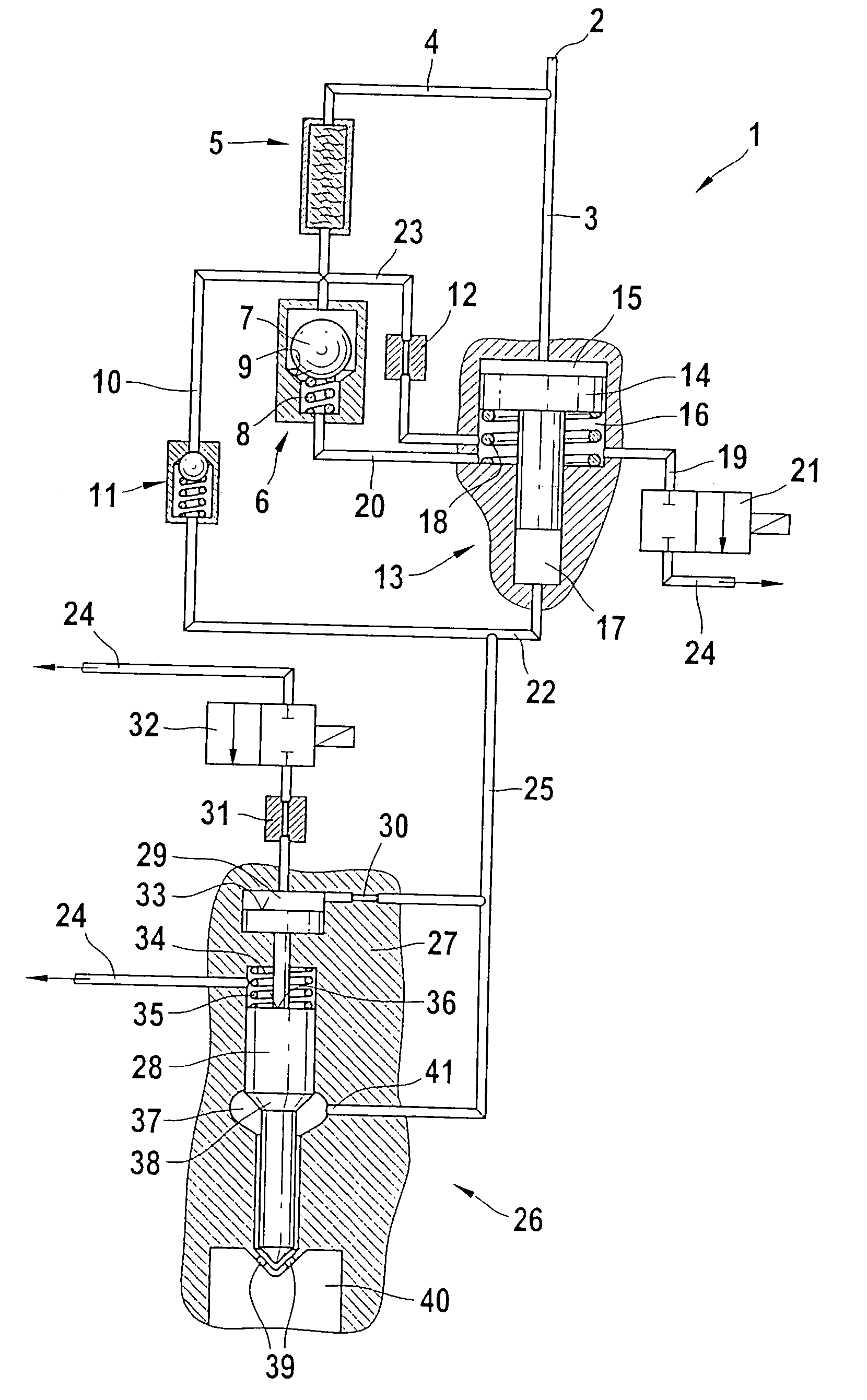

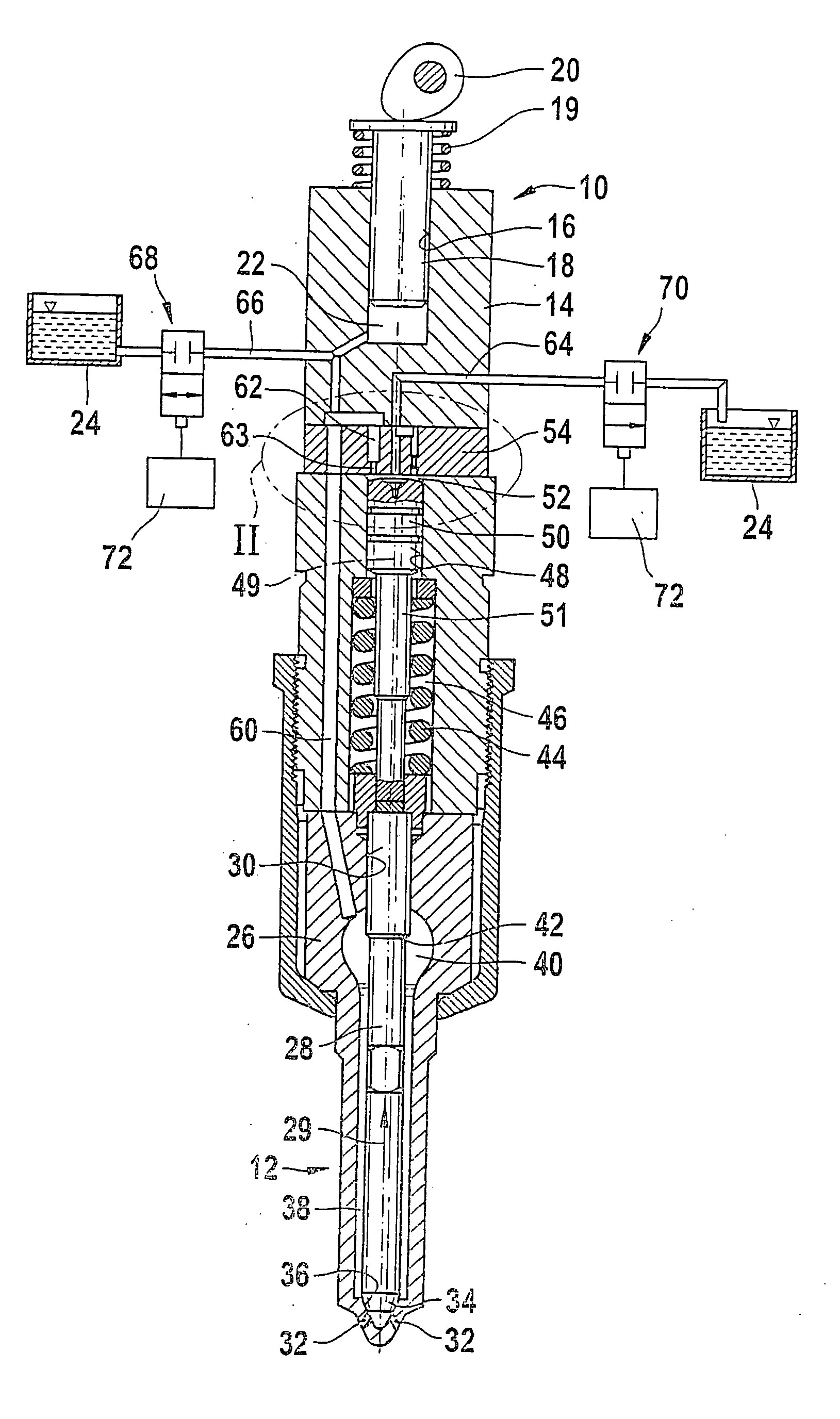

Filter arrangement for fuel injection systems

InactiveUS20060005815A1Improve fuel injection efficiencyImprove efficiencyMachines/enginesFuel injecting pumpsHigh pressure chamberFuel injection

A fuel injection system for internal combustion engines, having a fuel injector that can be acted upon by a high-pressure fuel source includes a pressure booster, which contains a movable boosting element dividing a work chamber which can be made to communicate with the high-pressure source via a high-pressure line from a high-pressure chamber that acts on the fuel injector. The high-pressure from chamber is variable by filling and evacuating a differential pressure chamber of the pressure booster. A filter element is received in a line portion that branches off from the high-pressure line and is upstream of flow connections for filling the differential and high pressure chambers.

Owner:ROBERT BOSCH GMBH

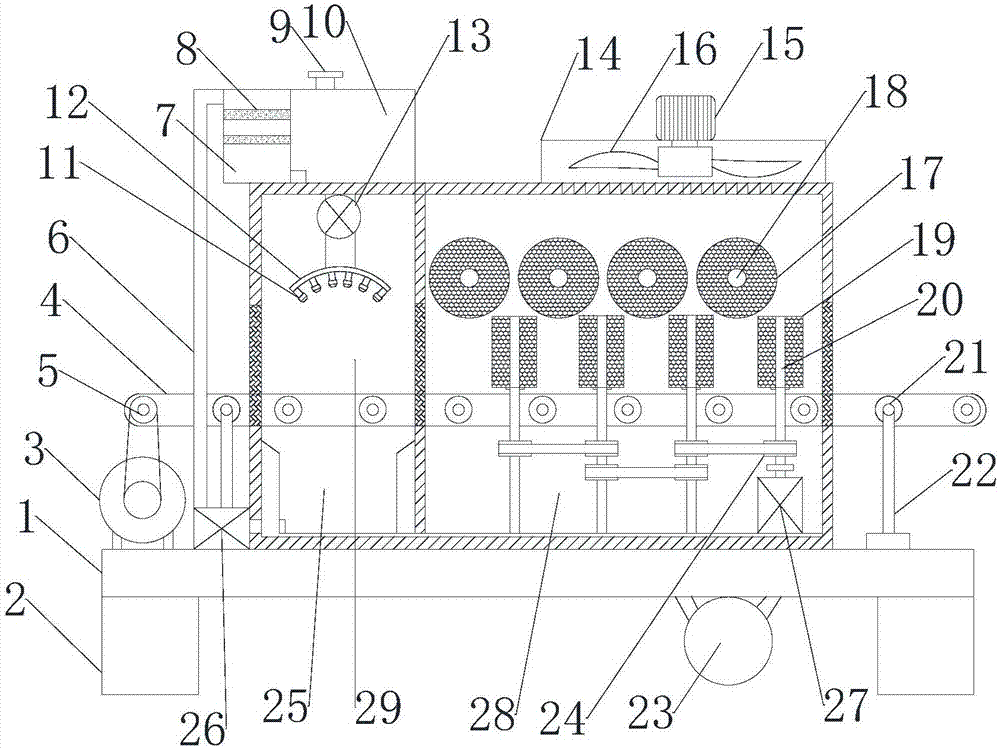

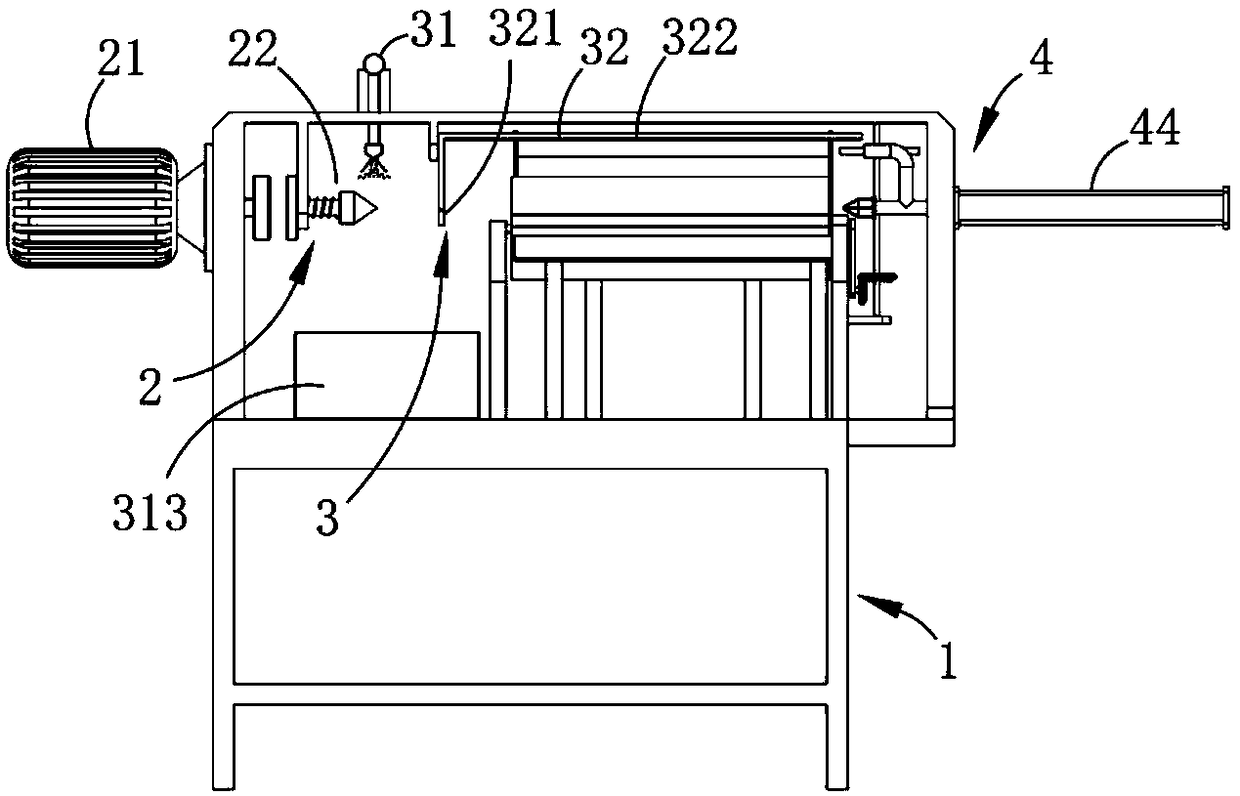

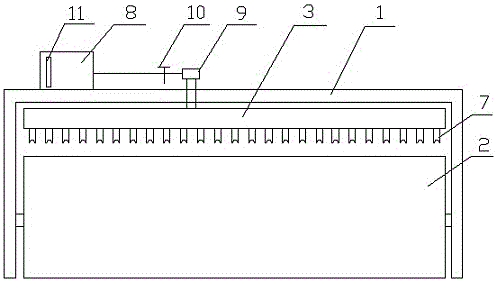

Efficient and economical lubricating oil spraying device

PendingCN107876321AImprove application and wiping speedReasonable designLiquid surface applicatorsCoatingsSpray nozzleProcess engineering

The invention discloses an efficient and economical lubricating oil spraying device. The efficient and economical lubricating oil spraying device comprises a base, a conveying belt, an oil spraying box and a wiping box. The bottom end of the interior of the oil spraying box is provided with an oil storage trough. The lower end of a second oil pump is connected with the arc base through an oil pipe. The lower end of the arc base is provided with a plurality of spraying nozzles. According to the efficient and economical lubricating oil spraying device, reasonable design is achieved in structure,operation is convenient and quick, and the practicality is very high; during working, under the action of the oil spraying box, a object to be oil-sprayed is oil-sprayed; under the action of the arcbase and the spraying nozzles, oil spraying is concentrated, and the oil spraying efficiency is improved; the oil storage trough collects the dripping lubricating oil, the dripping lubricating oil enters a filtering box through a first oil pump and is filtered through a filtering membrane to enter an oil box, and recycling, environmental protection and economy are achieved; under joint action of awiping sleeve and a smearing sleeve, the smearing and wiping speed of the lubricating oil is increased, and the lubricating oil is smeared more evenly; and under action of a fan, the operating temperature of the device is reduced, the oil quality is ensured, and the lubricating effect is improved.

Owner:WUXI FEITIAN GREASE

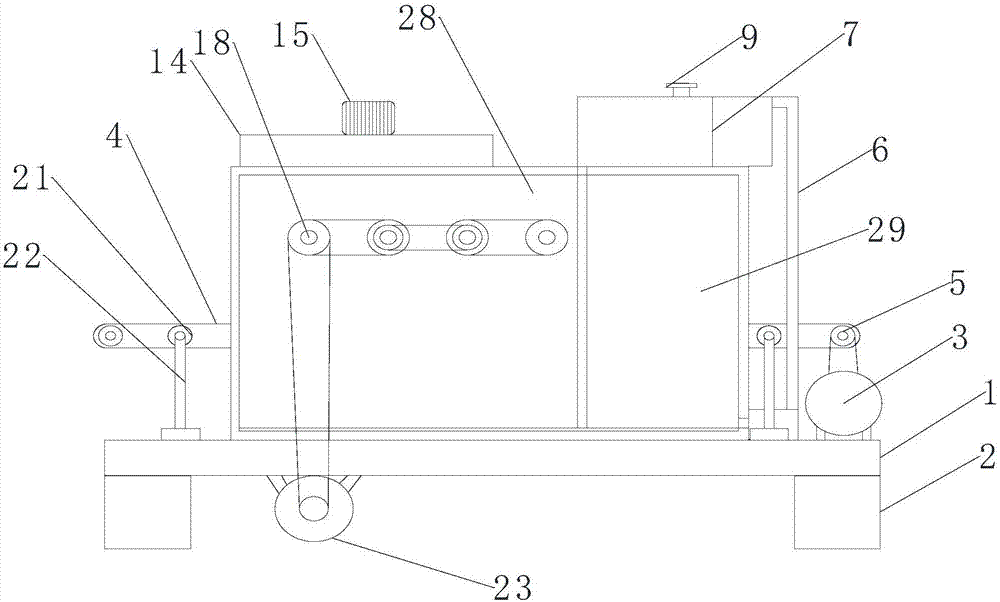

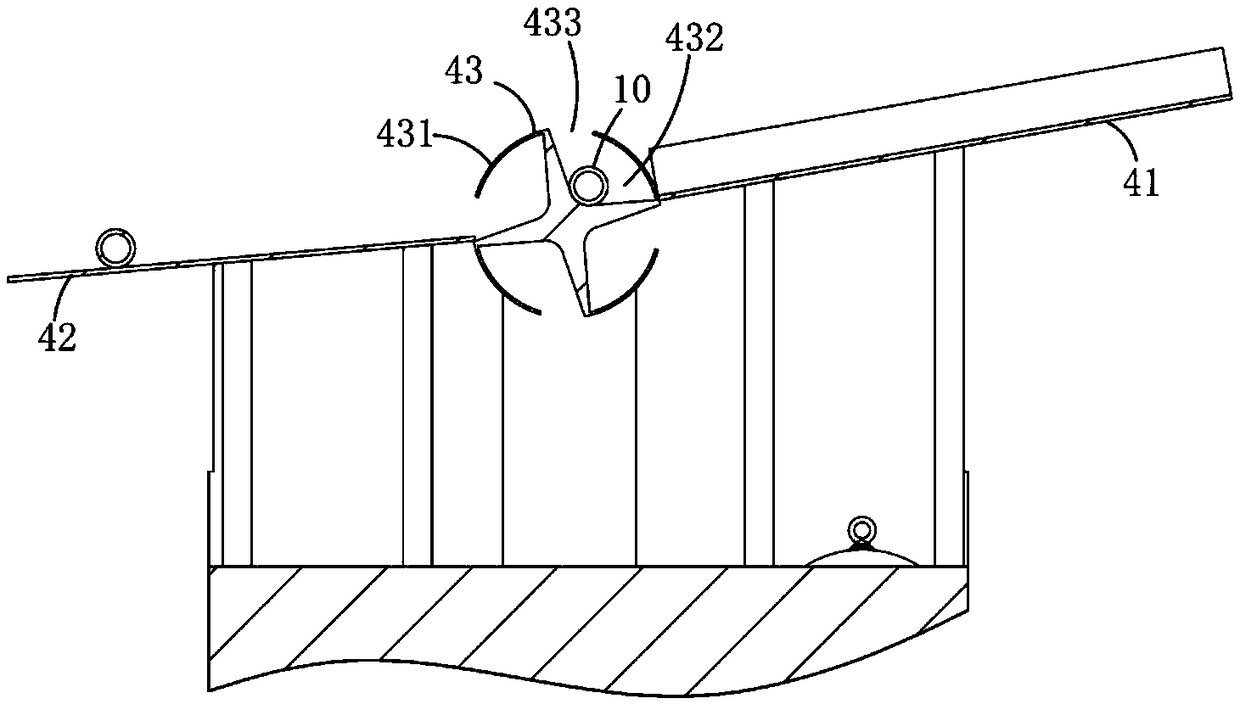

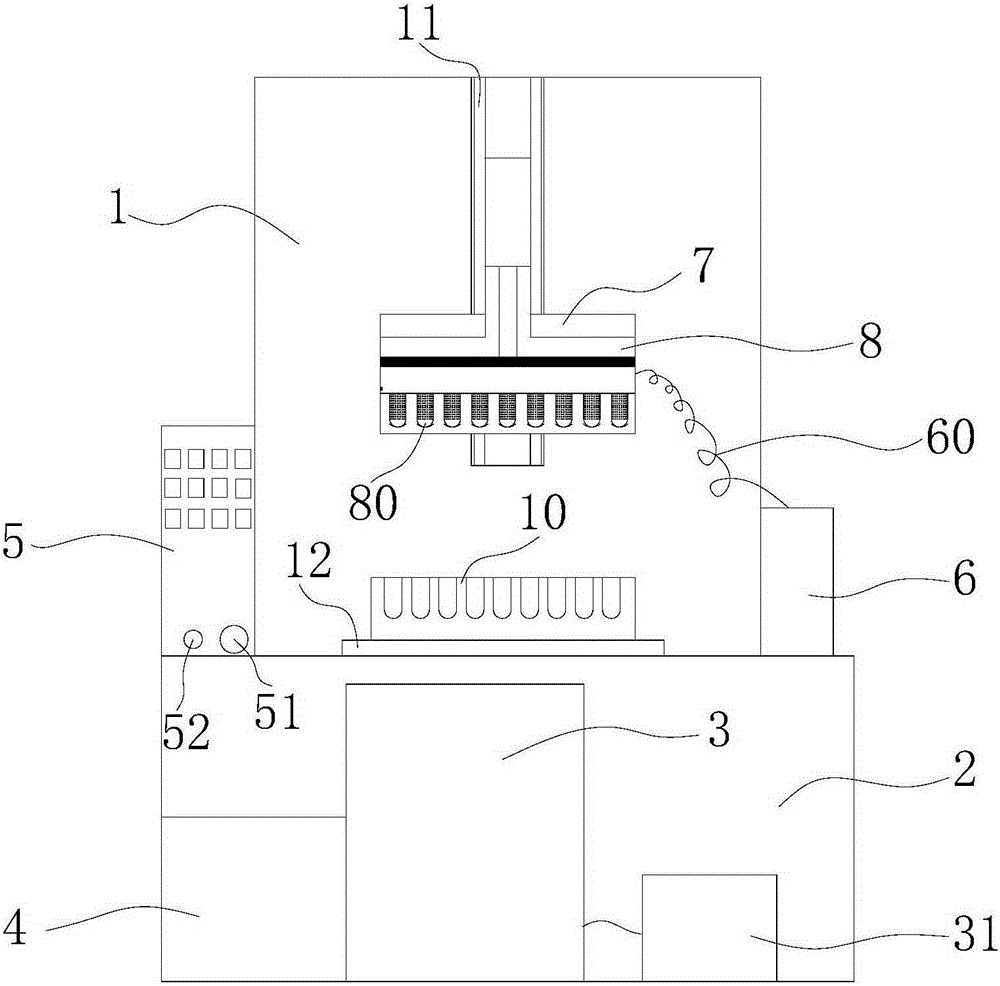

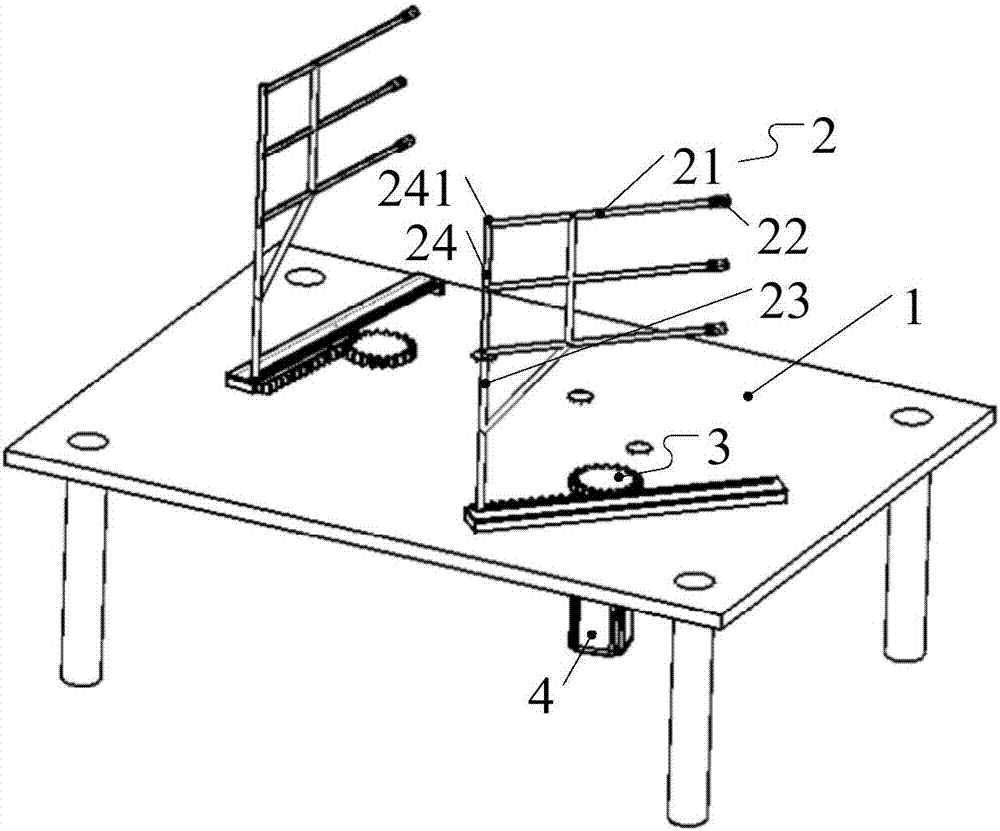

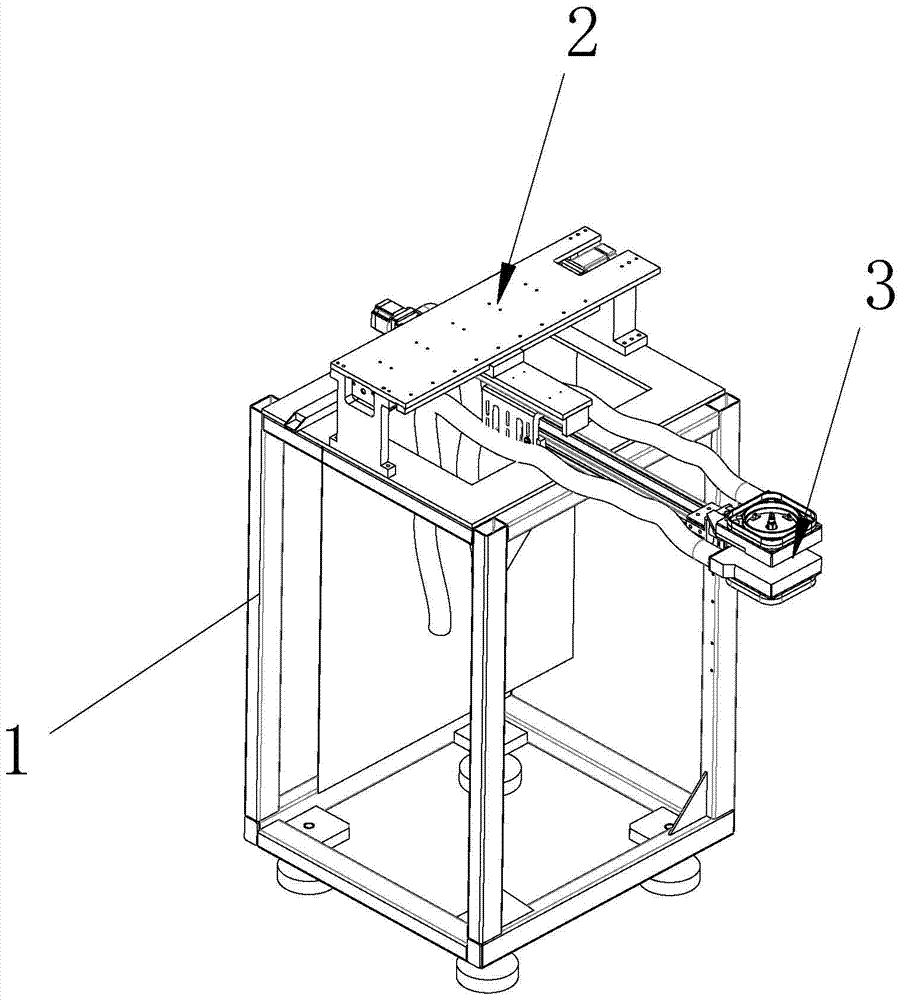

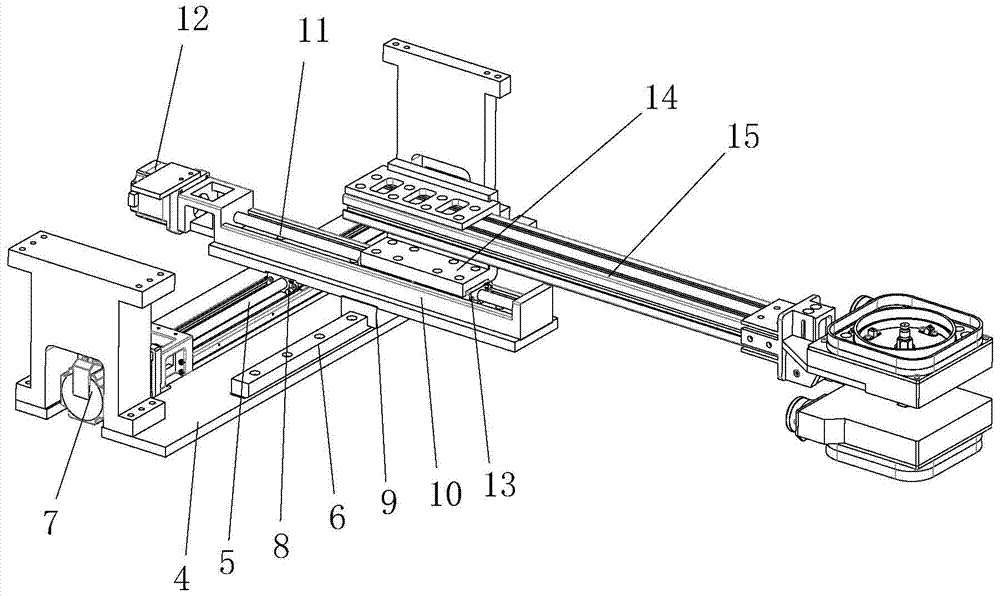

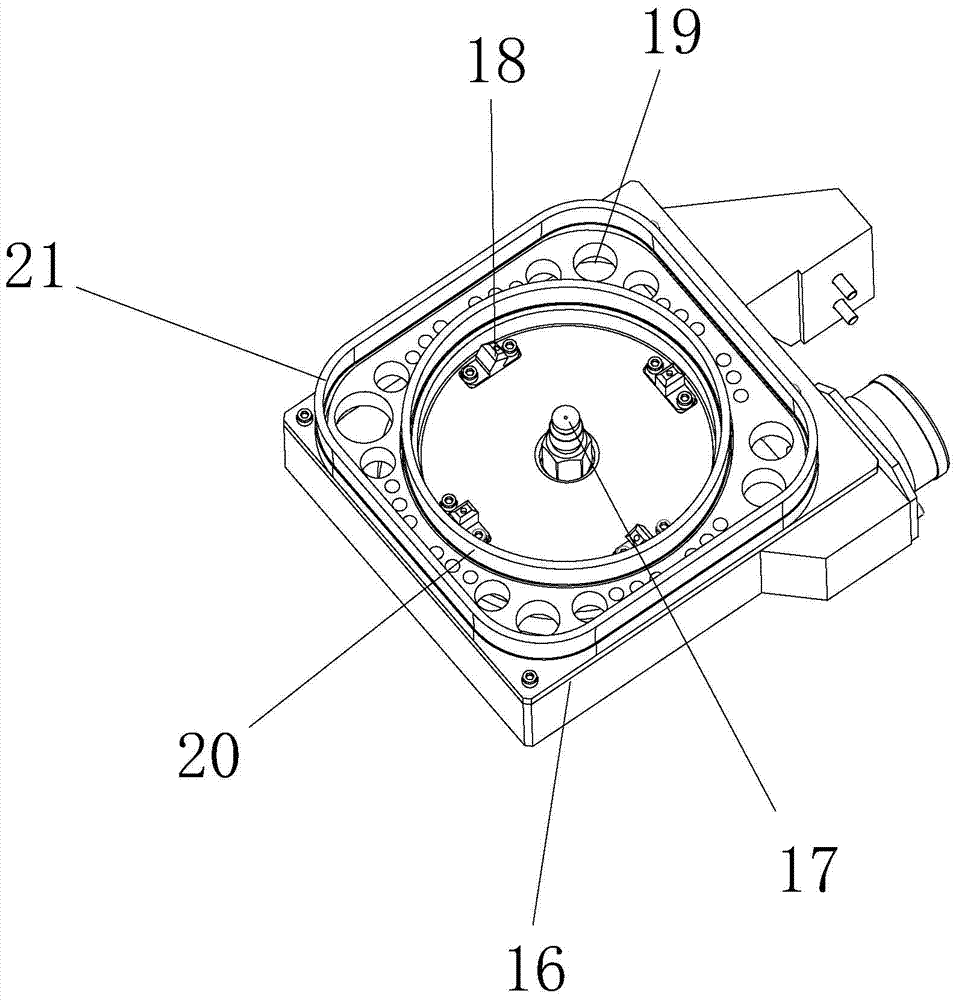

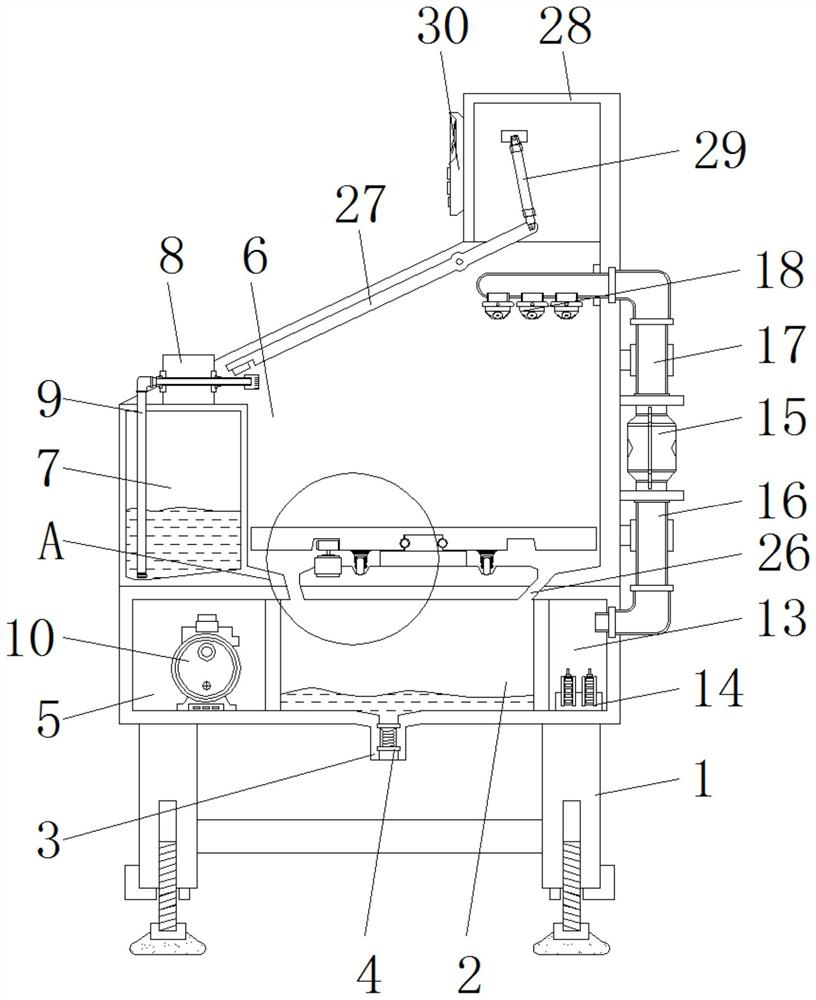

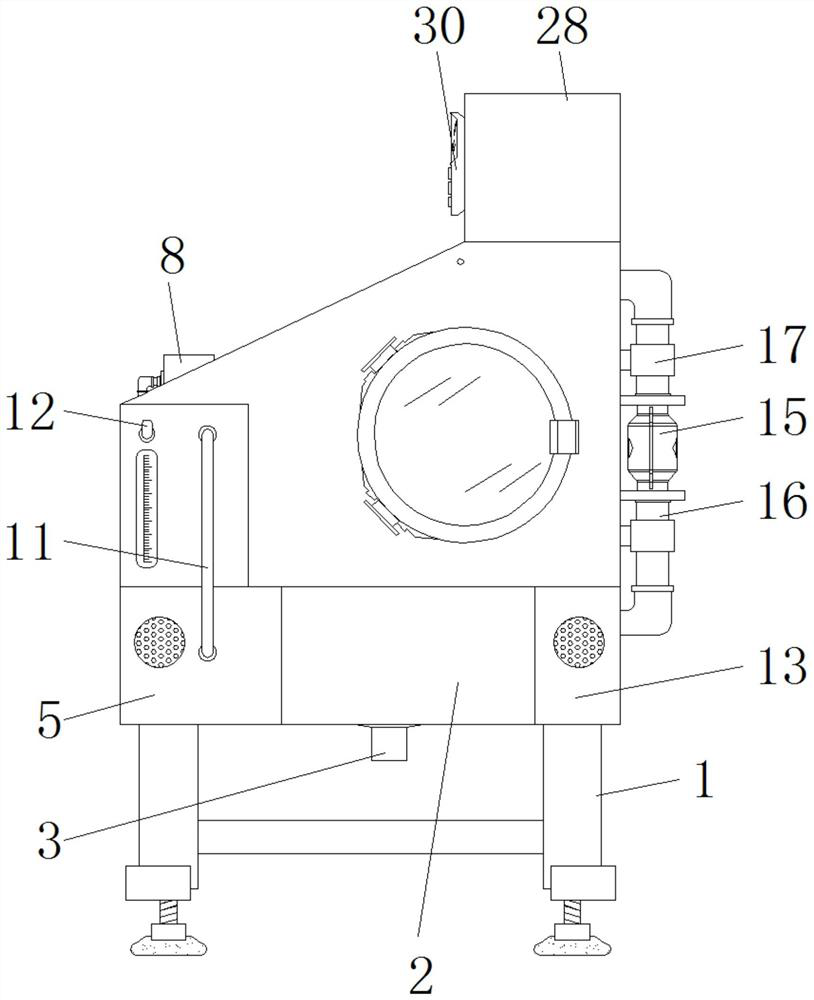

Automatic production device for carrying out rust-proof treatment on end part of steel pipe

InactiveCN108704787ARealize automatic outputUniform coating productionLiquid spraying apparatusReciprocating motionEngineering

The invention relates to the technical field of steel pipe processing and production, in particular to an automatic production device for carrying out rust-proof treatment on the end part of a steel pipe. The automatic production device for carrying out rust-proof treatment on the end part of the steel pipe comprises a rack, a positioning mechanism, an oil coating mechanism and a material transferring mechanism, wherein the oil coating mechanism comprises an oil spraying assembly and a coating assembly located at one end of the oil spraying assembly and is far away from the positioning mechanism; the material transferring mechanism comprises a loading assembly, a blanking assembly for outputting the steel pipe, a limiting assembly arranged between the loading assembly and the blanking assembly and intermittently communicating with the loading assembly and the blanking assembly, and a pushing assembly for transferring the steel pipe in the limiting assembly into the oil spraying mechanism; the limiting assembly is driven by the pushing assembly so as to directionally rotate; the coating assembly is driven by the pushing assembly so as to contact the steel pipe; and during the process that the pushing assembly sprays oil to the steel pipe and conveys the steel pipe through a reciprocating motion way, the steel pipe rotates and is coated with anti-rust oil and automatically outputted, so that the automatic oil coating production of the steel pipe is realized, and the technical problem of low production efficiency in the prior art is solved.

Owner:长兴新亚环保机械科技股份有限公司

Methods and systems for fixed and variable pressure fuel injection

ActiveUS9611801B2Less powerEasy to chargeElectrical controlInternal combustion piston enginesRail pressureSystem configuration

Methods and systems are provided for operating a high pressure injection pump to provide each of high fixed fuel pressure at a first direct injection fuel rail and high variable fuel pressure at a second direct injection fuel rail. The direct injection fuel rail pressure can be raised above a pressure provided with a lift pump via a fuel system configuration that includes various check valves, pressure relief valves, and a spill valve positioned between an inlet of the high pressure injection pump and the port injection fuel rail. Fixed and variable high pressure direct injection may be advantageously used to provide learn the ballistic region of each direct injector.

Owner:FORD GLOBAL TECH LLC

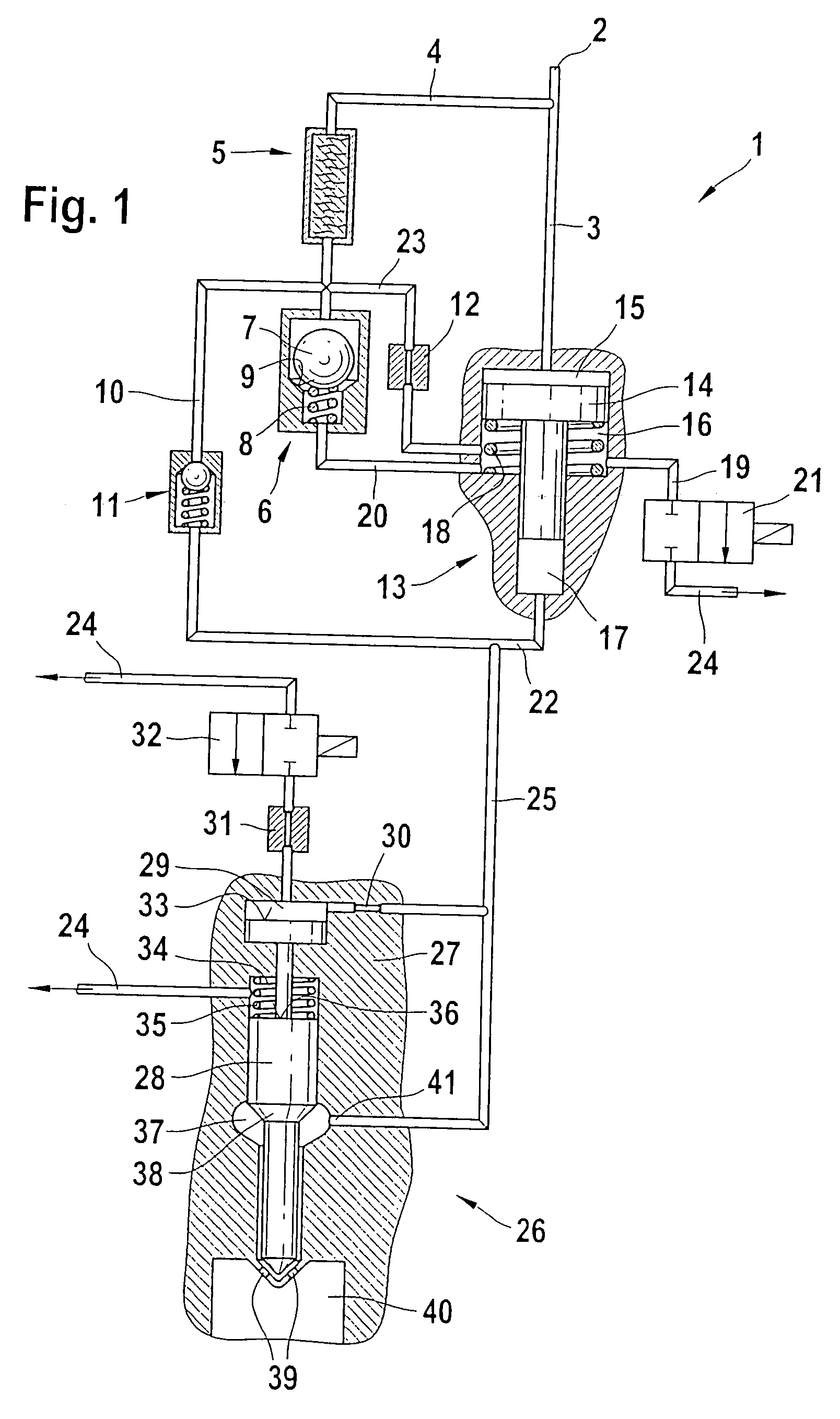

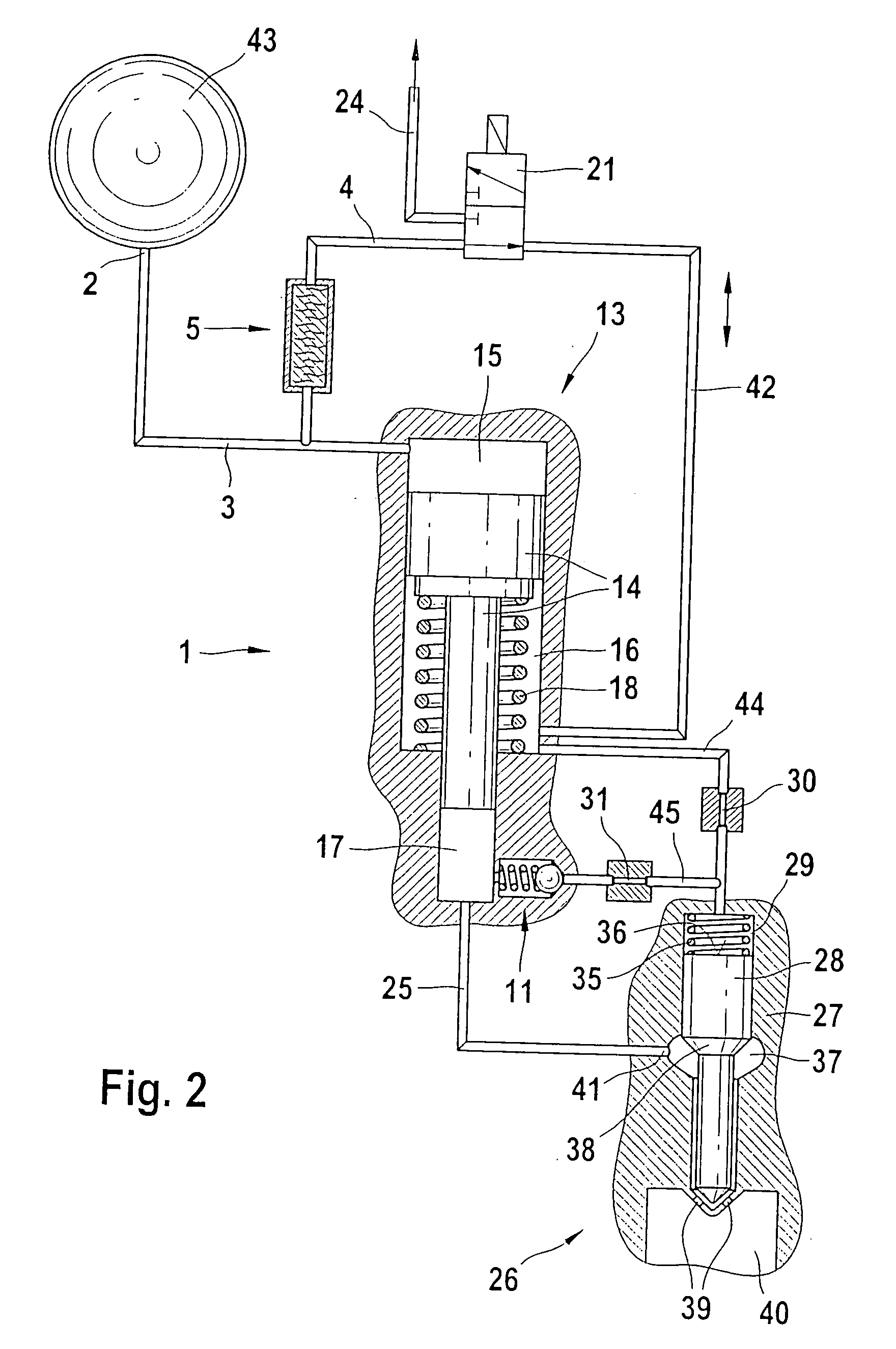

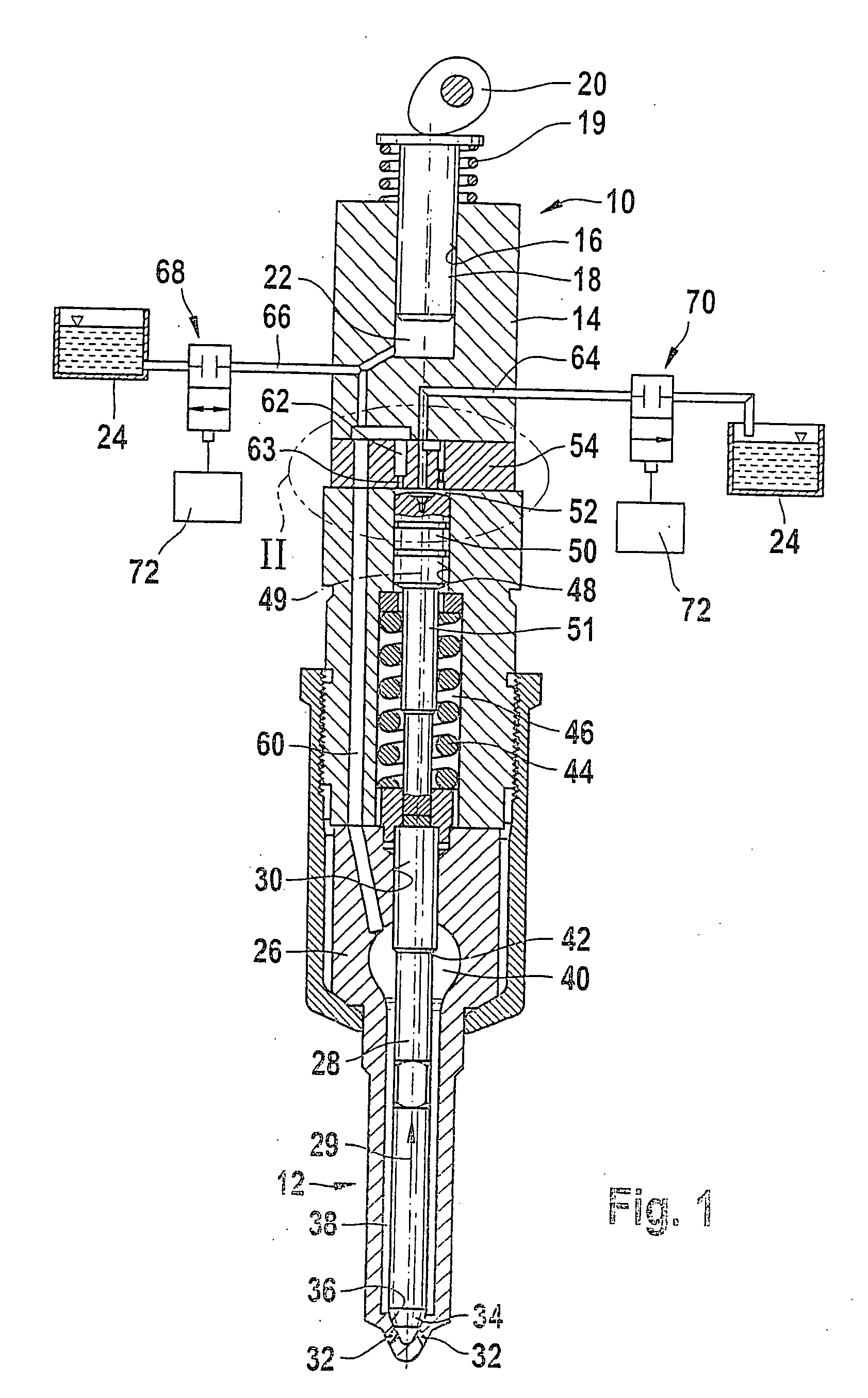

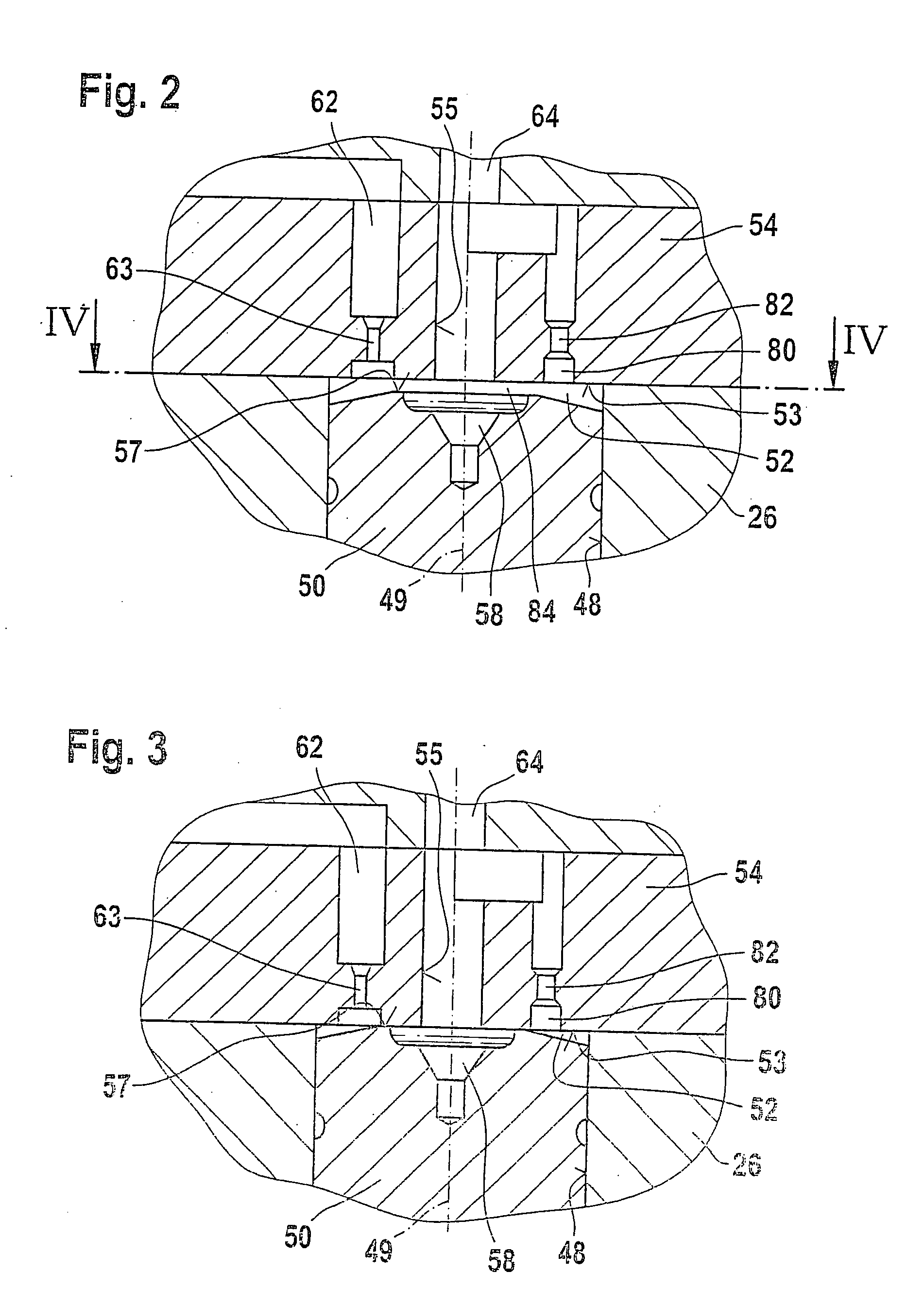

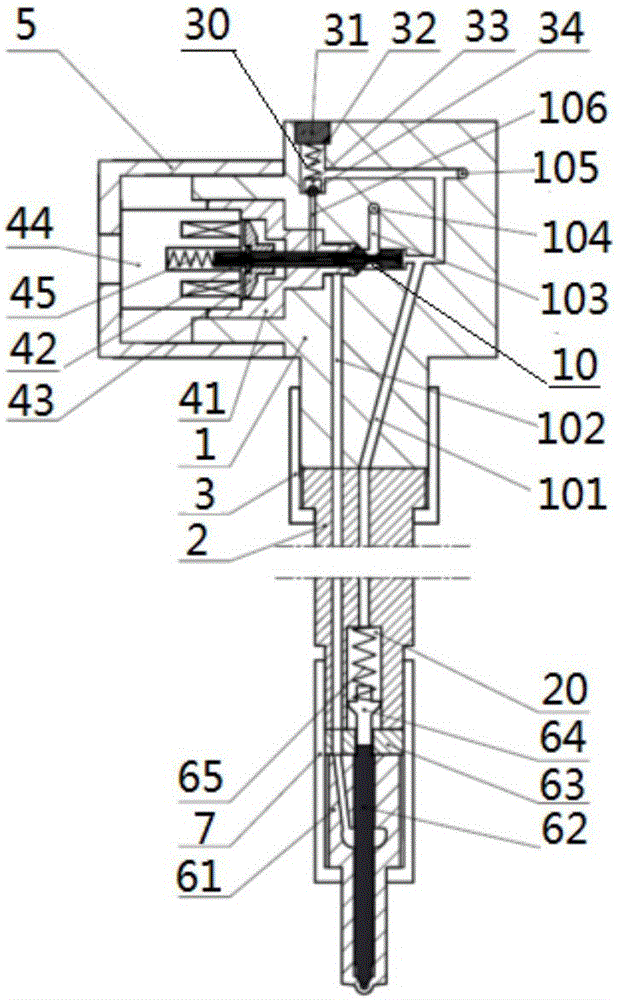

Fuel injection device for an internal combustion engine

InactiveUS20040144366A1Increase pressureEasy to controlLow pressure fuel injectionFuel injection with piezoelectric/magnetostrictive elementsEngineeringInternal combustion engine

The fuel injection apparatus has a high-pressure fuel pump (10) and a fuel injection valve (12) connected to it for each cylinder of the internal combustion engine. A pump piston (18) of the high-pressure fuel pump (10) delimits a pump working chamber (22), which is connected to a pressure chamber (40) of the fuel injection valve (12), which has a injection valve element (28) that can control injection openings (32) and can be moved in an opening direction (29) counter to a closing force by the pressure prevailing in the pressure chamber (40). A control valve (70) controls a connection (64) of a control pressure chamber (52), which communicates with the pump working chamber (22) and is delimited by a control piston (50), to a relief chamber (24). When the injection valve element (28) is in its closed position, the control piston (50) opens a main connection (84) with a large flow cross section and when the injection valve element (28) is in its open position, this control piston (50) closes the main connection (84) and only opens a bypass connection (80) with a small flow cross section, wherein the bypass connection (80) is embodied in a housing part (54) that delimits the control pressure chamber (52).

Owner:ROBERT BOSCH GMBH

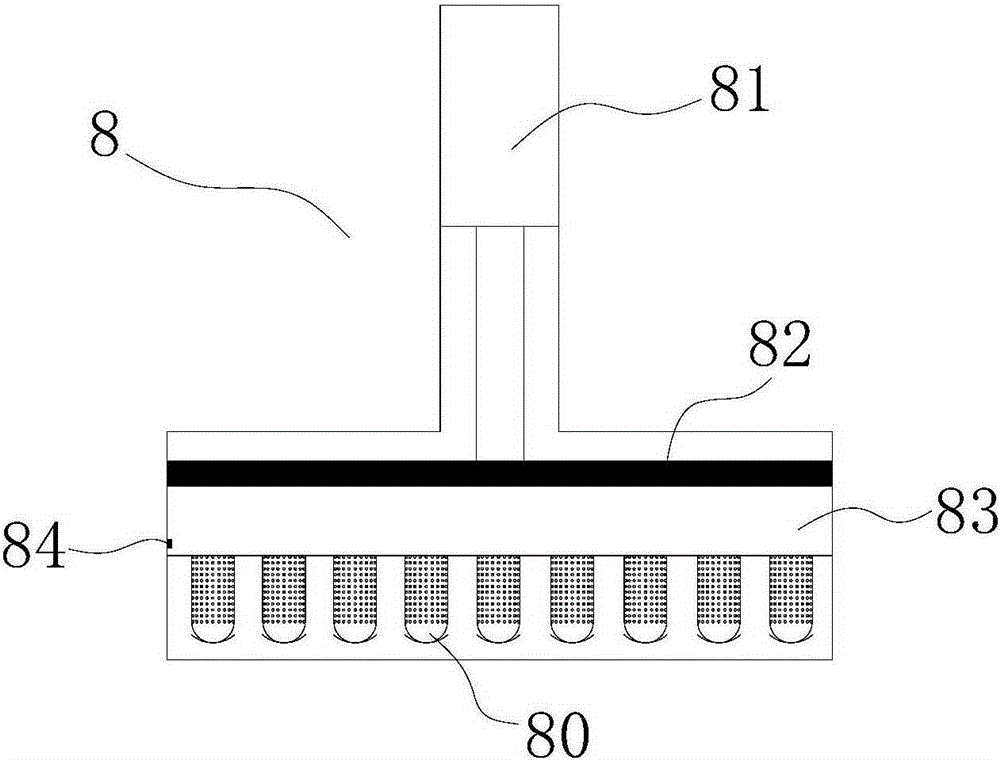

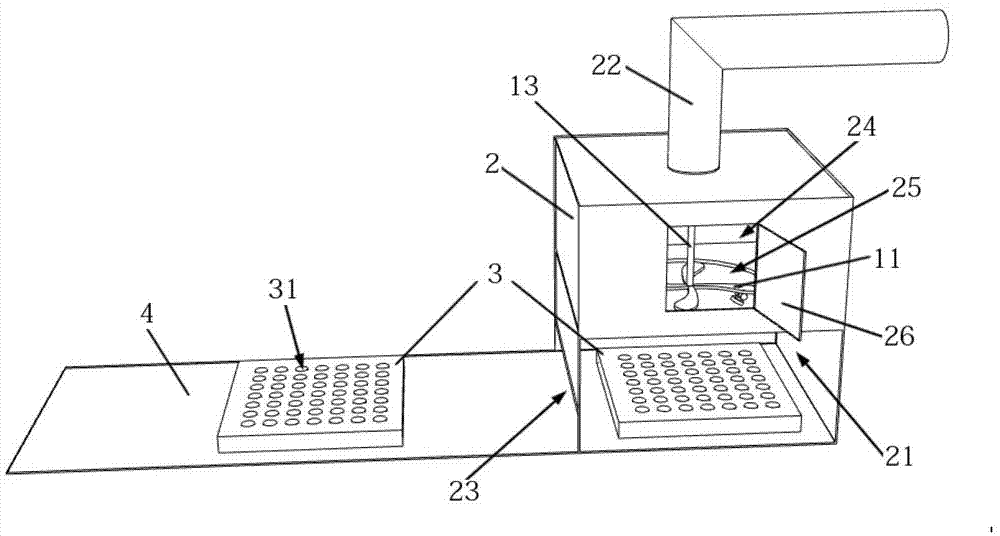

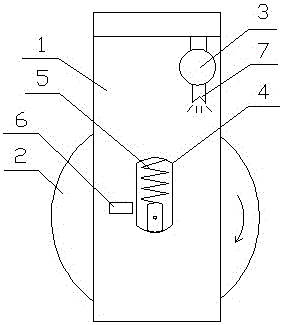

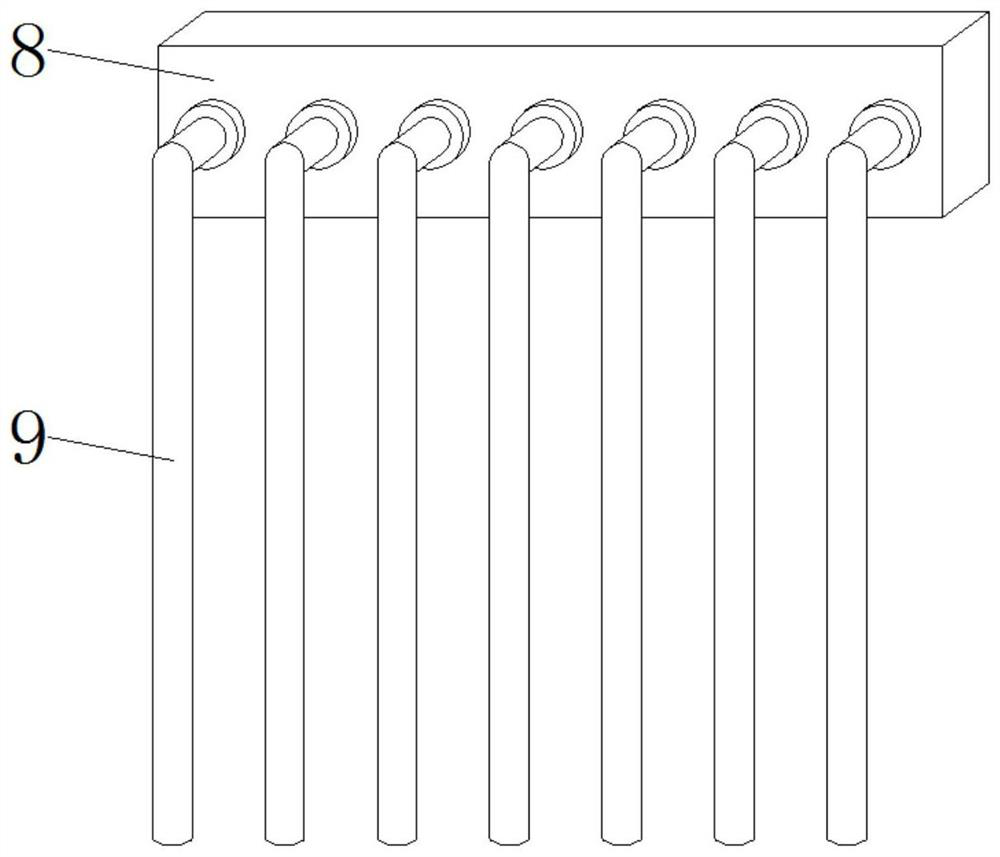

Automatic oil spraying device for hollow capsule blank

ActiveCN105268580AImprove distribution uniformityGood release effectSpraying apparatusBristleEngineering

The invention discloses an automatic oil spraying device for a hollow capsule blank. The automatic oil spraying device comprises a rack body, a base, a servo motor, a control device, an oil supplying device, a feeding mechanism and an oil spraying executing mechanism. The rack body is located on the base. The rack body is provided with a double-sliding-track sliding rail. The feeding mechanism can be installed on an outer sliding track of the double-sliding-track sliding rail in a sliding manner. The oil spraying executing mechanism can be installed on an inner sliding track of the double-sliding-track sliding rail in a sliding manner. The oil spraying executing mechanism comprises an air cylinder, a sealing push plate, an oil storage groove, an oil quantity sensing device and a plurality of oil spraying steel rods. A capsule blank clamp is installed under the oil spraying executing mechanism, and the servo motor, the control device and a servo driving device are installed in the base. The automatic oil spraying device for the hollow capsule blank is reasonable in structure, the oil spraying executing mechanism of a mechanical structure is used for replacing an original brush, the problem of bristle slip of the brush is solved, the demolding effect of a capsule cap and a capsule body is improved, and meanwhile the production quality of a hollow capsule is improved.

Owner:浙江绿健胶囊有限公司

Methods and systems for fixed and variable pressure fuel injection

ActiveUS9752530B2Less powerEasy to chargeElectrical controlFuel injection apparatusRail pressureEngineering

Methods and systems are provided for operating a high pressure injection pump to provide each of high fixed fuel pressure at a port injection fuel rail and high variable fuel pressure at a direct injection fuel rail. Port injection fuel rail pressure can be raised above a pressure provided with a lift pump via a fuel system configuration that includes various check valves, pressure relief valves, and a spill valve positioned between an inlet of the high pressure injection pump and the port injection fuel rail. High pressure port injection may be advantageously used to provide fuel at high pressure during conditions when fuel delivery via high pressure direct injection is limited.

Owner:FORD GLOBAL TECH LLC

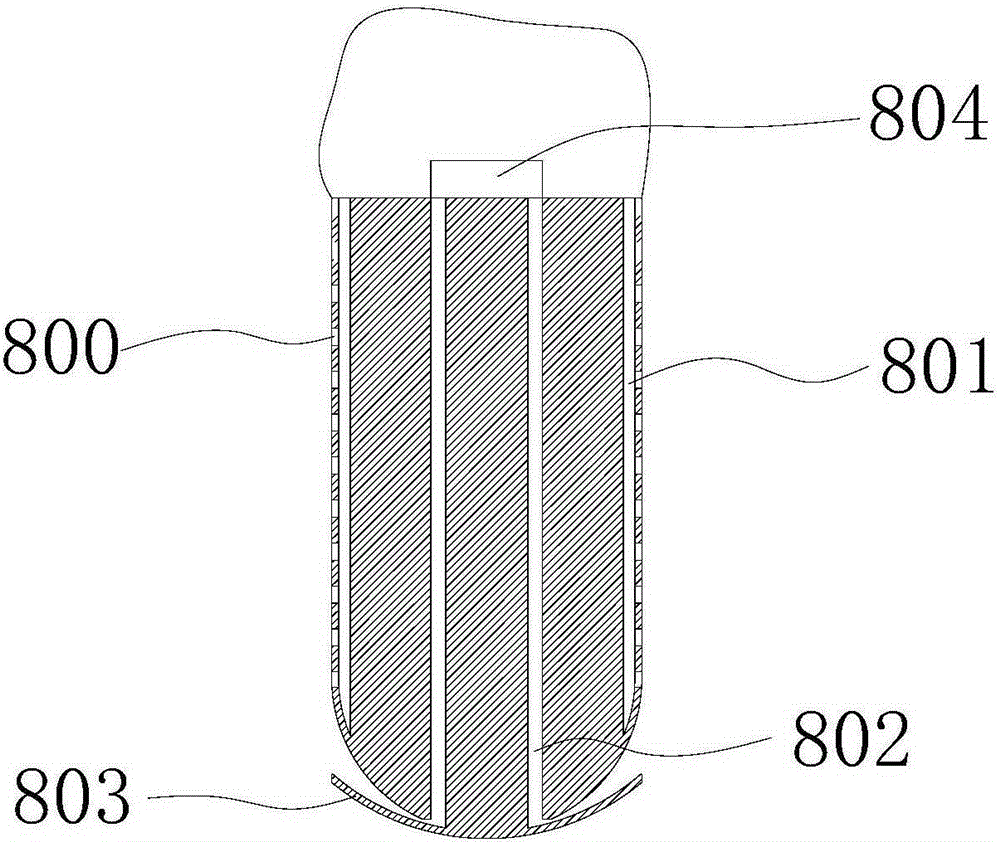

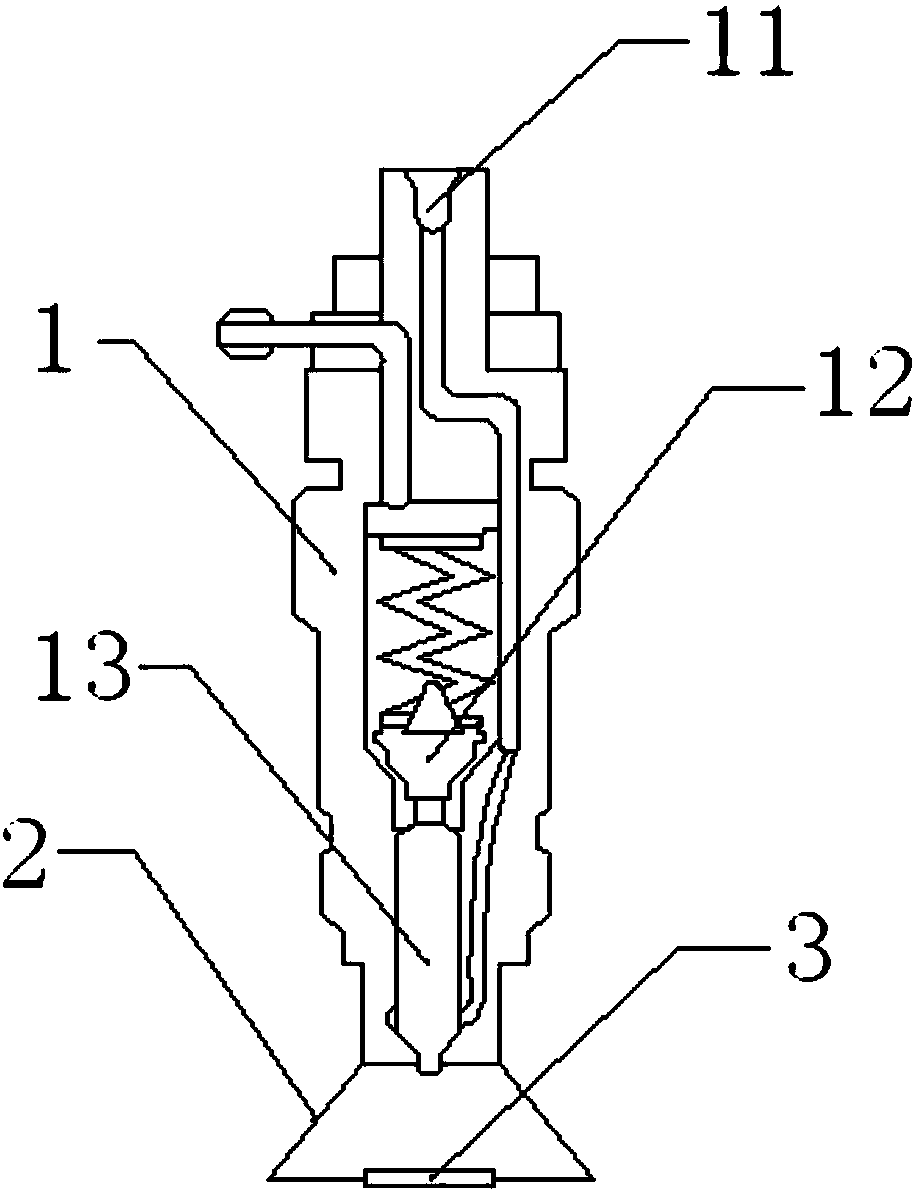

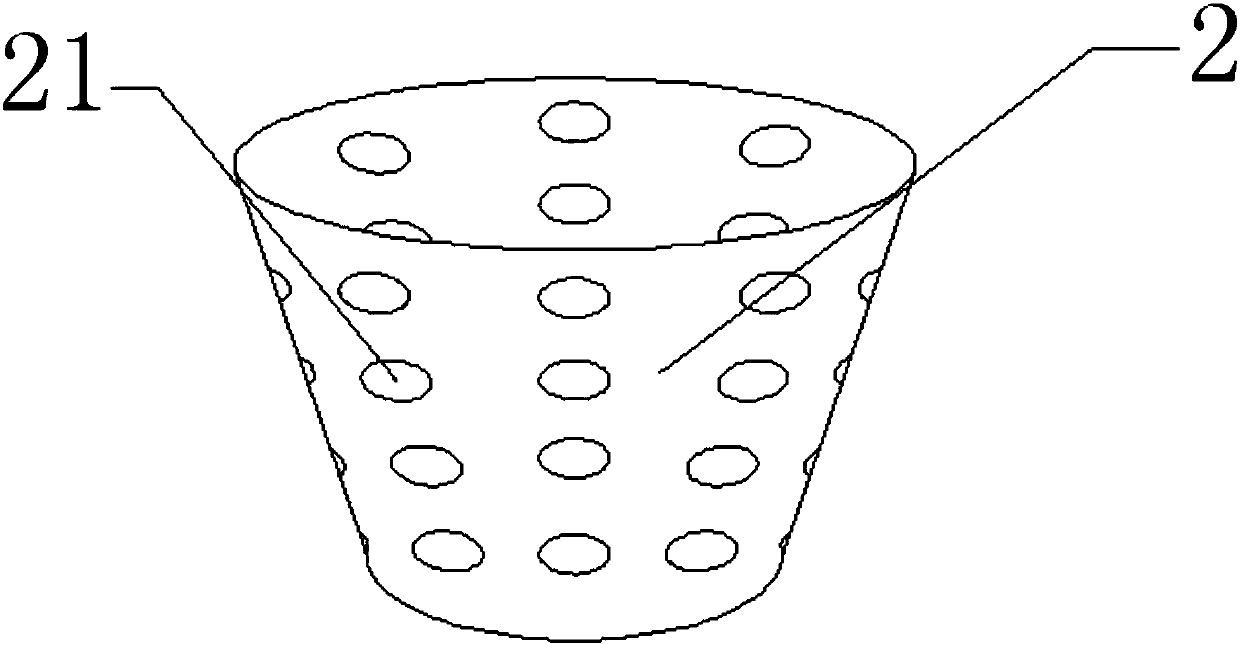

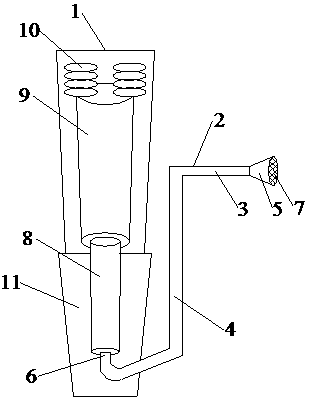

Atomization oil nozzle capable of improving oil injection efficiency

InactiveCN108049998AImprove fuel injection efficiencyInjection Efficiency AdjustmentFuel injection apparatusMachines/enginesNeedle valvePetroleum engineering

The invention discloses an atomization oil nozzle capable of improving the oil injection efficiency. The atomization oil nozzle comprises an oil nozzle part; a filter screen, a solenoid electric valveand a needle valve are arranged in the oil nozzle part; the filter screen is arranged on an oil outlet of the oil nozzle part; the solenoid electric valve is arranged below the oil outlet; and the needle valve is arranged below the solenoid electric valve. The atomization oil nozzle is characterized in that the atomization oil nozzle further comprises a dispersion cover arranged at the end face of the lower part of the oil nozzle part; an atomization fan is arranged on the dispersion cover; and after the needle valve sprays oil liquid, the oil liquid is dispersed through the atomization fan on the outer side of the oil nozzle part, and the dispersion range is controlled through the dispersion cover. With the adoption of the atomization fan, through the positive rotation and negative rotation of the atomization fan, the dispersion area is raised or the atomization efficiency is improved, and the dispersion efficiency of the atomization oil nozzle can be improved through the adopted dispersion cover. When oil injection is required, the solenoid electric valve is started to upwards suck the needle valve, a needle valve port is opened, and the oil liquid is sprayed out of the needle valve.

Owner:四川天人能源科技有限公司

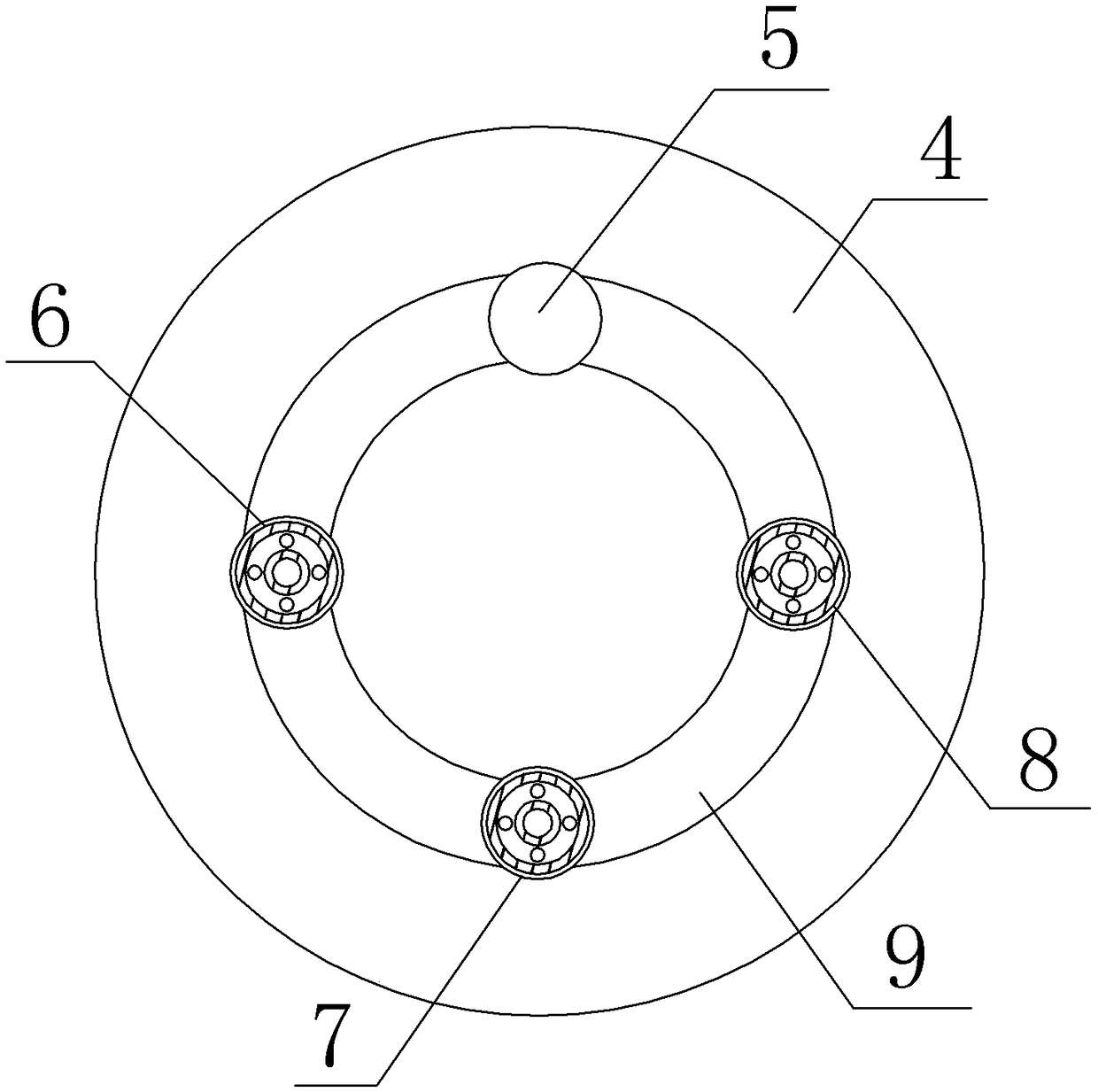

Mechanical part maintenance process

InactiveCN108071924AImprove fuel injection efficiencySimplify the oiling procedureBearing componentsDistribution equipmentMachine partsInjection equipment

The invention relates to the field of bearing oil injection, in particular to a mechanical part maintenance process. The mechanical part maintenance process comprises the following steps that 1, mechanical part oil injection equipment is prepared, wherein a rotating disc is provided with N vertical holes; 2, bearings are placed into (N-1) vertical holes correspondingly; 3, oil injection is conducted on the bearings through an oil injection nozzle when the bearings rotate along with the rotating disc; 4, a part placing unit and a part picking unit move toward the rotating disc, and the part placing unit drives the bearing on a first support mechanism to move when the part placing unit moves toward the rotating disc; and 5, after the part placing unit places the bearing on the first supportmechanism into the corresponding vertical hole and is in contact with the bearing obtained after oil injection, the part placing unit and the part picking unit move in the direction of being away fromthe rotating disc. By means of the mechanical part maintenance process, oil injection can be massively and continuously conducted on the bearings.

Owner:重庆婉婷科技发展有限公司

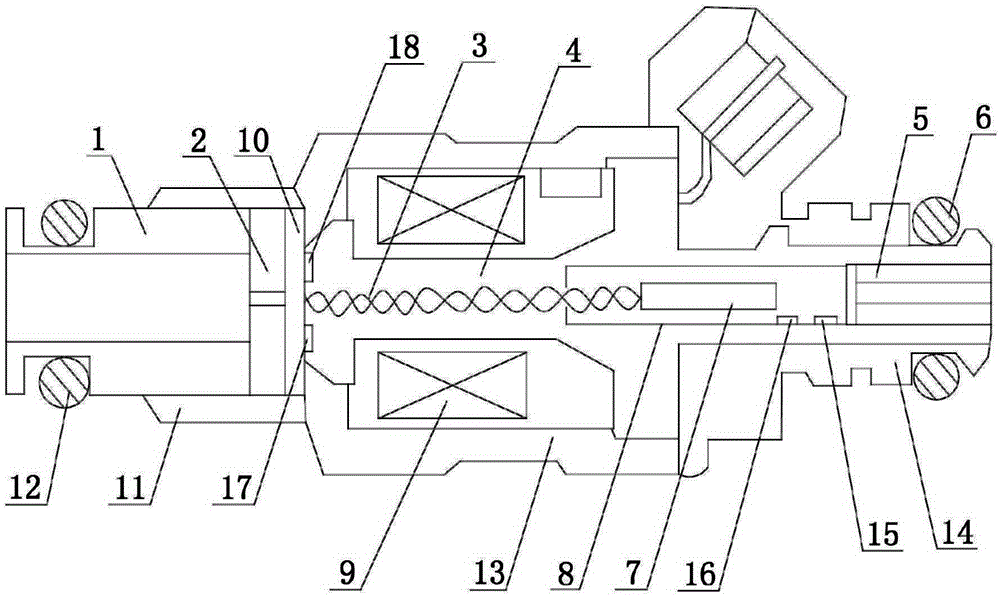

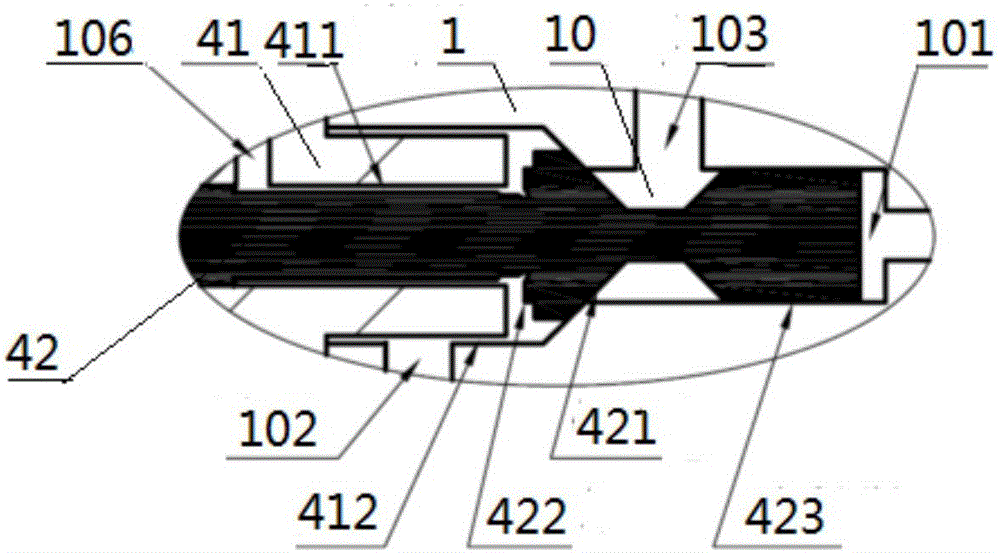

Novel electrically-controlled oil injector

ActiveCN106089522AOpen resistance is smallOpen fastFuel injection apparatusMachines/enginesHigh pressureElectromagnetic valve

The present invention provides a novel electrically-controlled oil injector, comprising an electromagnetic valve, a control piston, a control cavity, a one-way valve, a needle valve cavity, an oil nozzle, a high-pressure oil line and a low-pressure oil line; the high-pressure oil line includes three branches, one branch leads to the control cavity through an oil inflow hole and then leads to the low-pressure oil line through an oil outflow hole, another branch leads to the oil nozzle through a lower end valve of the control piston, the remaining branch leads to the oil nozzle needle valve cavity through the one-way valve and then leads to the low-pressure oil line through a throttle hole, and the control piston is never rigidly connected with the oil nozzle. The novel electrically-controlled oil injector has the advantages that pressure of the oil nozzle needle valve cavity is turned into low pressure so that it is possible to reduce opening resistance for an oil nozzle needle valve; the control piston is used to actively control opening and closing of the high-pressure oil line leading to the oil nozzle so that it is possible to reduce closing resistance for the oil nozzle needle valve; the one-way valve is used to increase an oil line leading to the upper end control cavity of the oil nozzle so that it is possible to increase closing power for the oil nozzle needle valve. It is possible to greatly increase the opening and closing speed of the oil nozzle needle valve, thereby increasing oil injection.

Owner:CHINA NORTH ENGINE INST TIANJIN

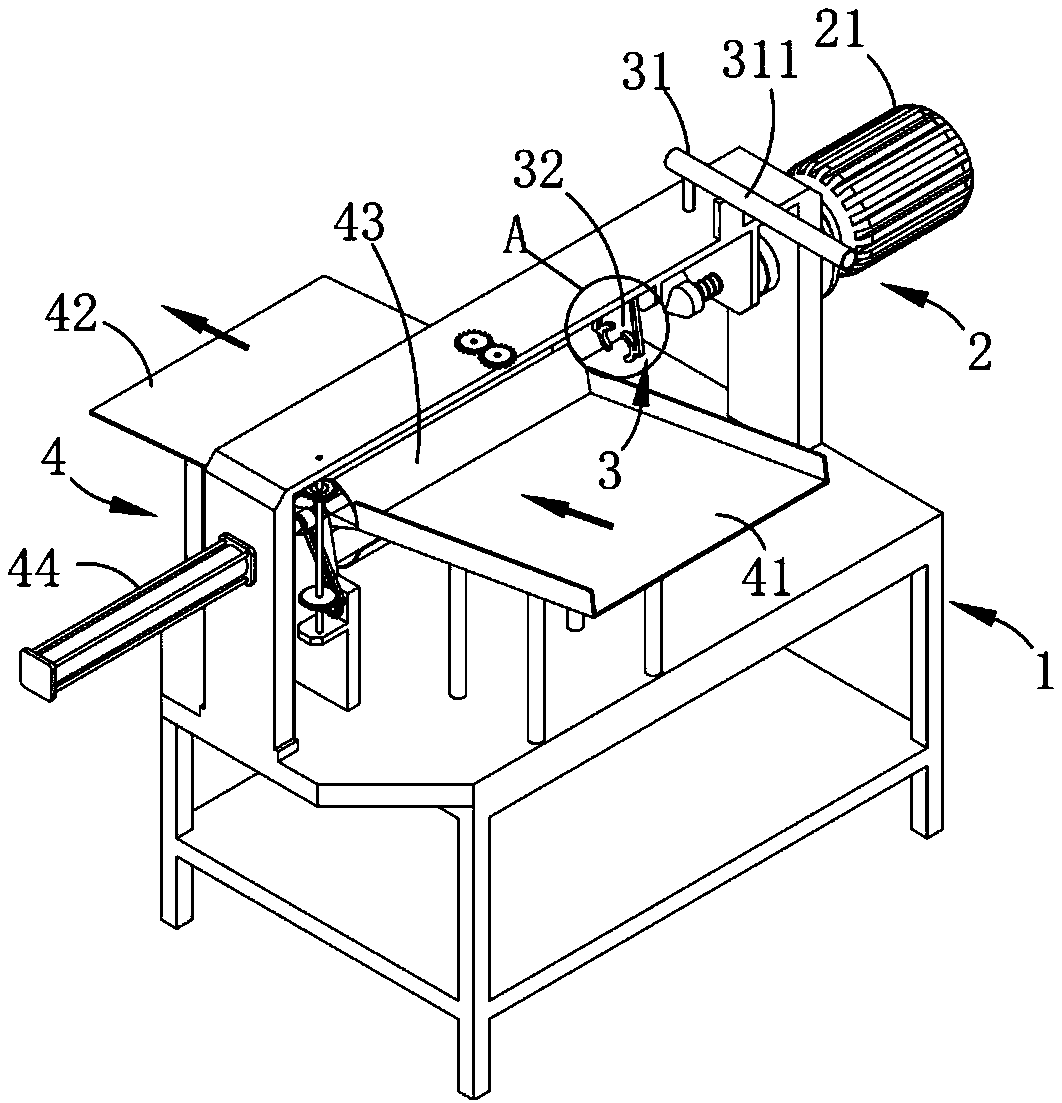

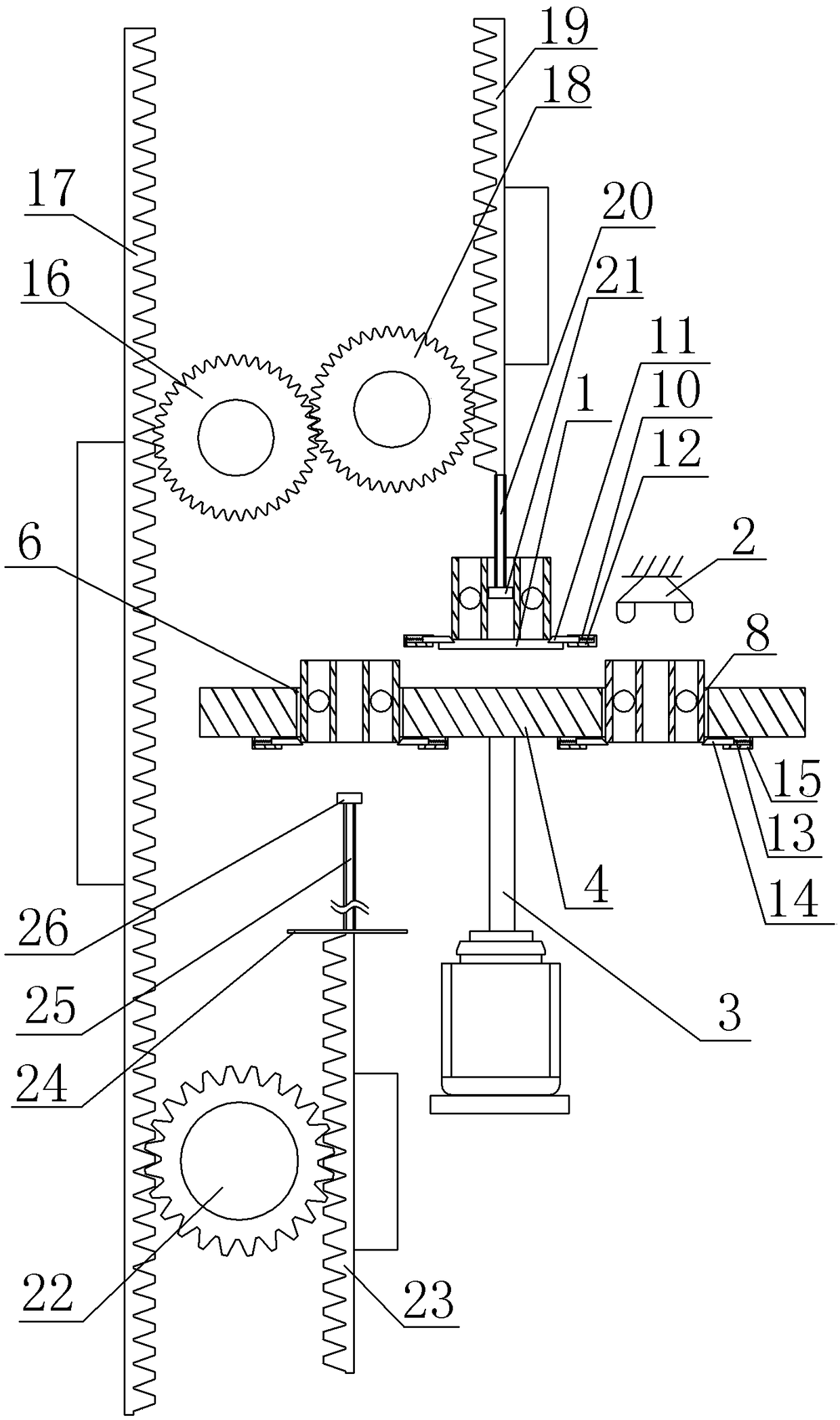

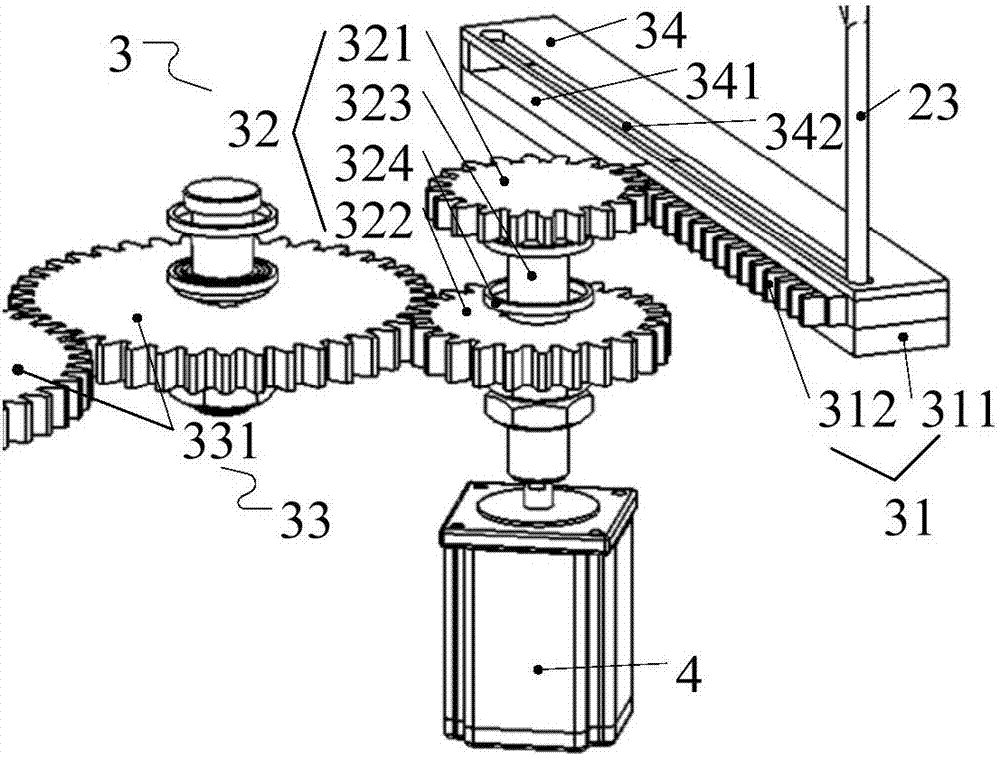

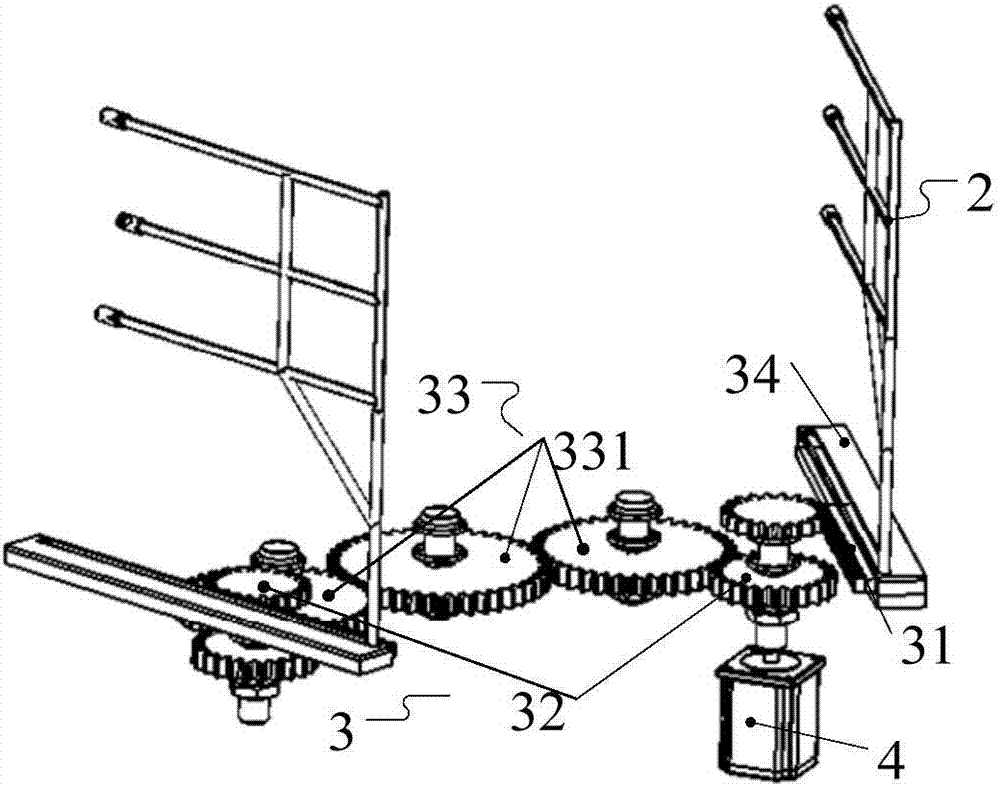

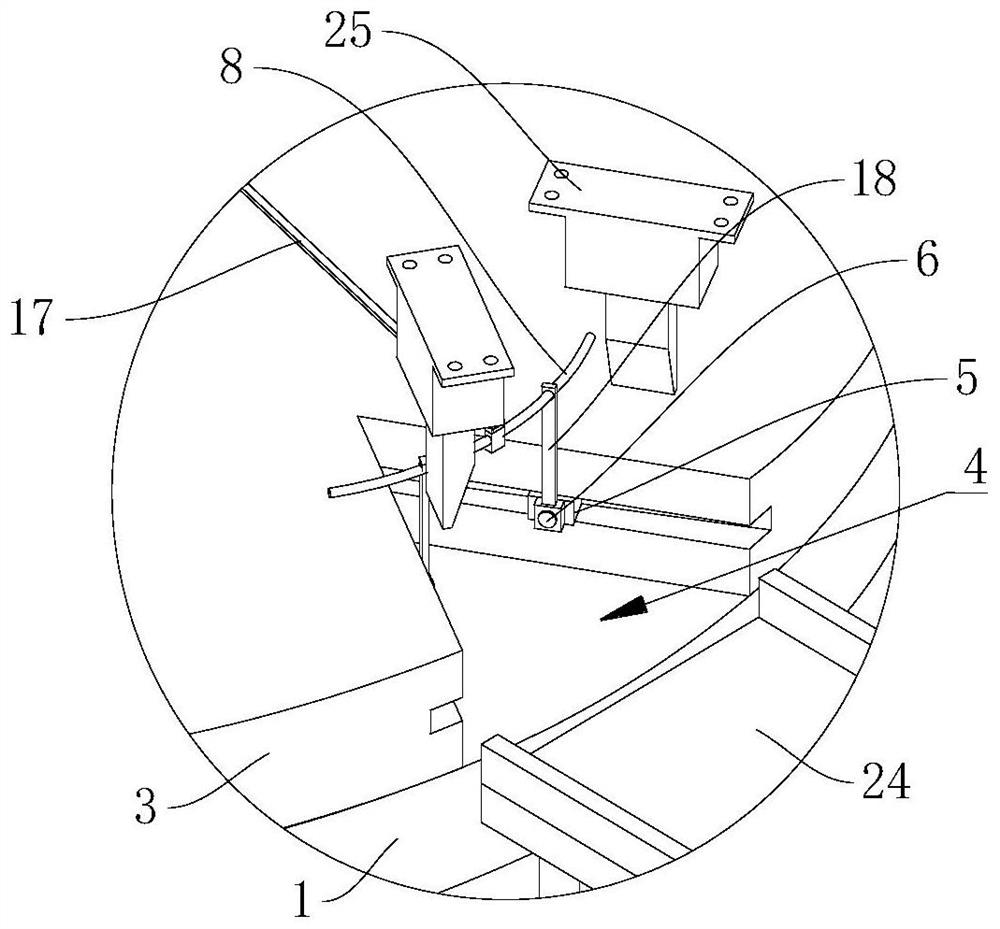

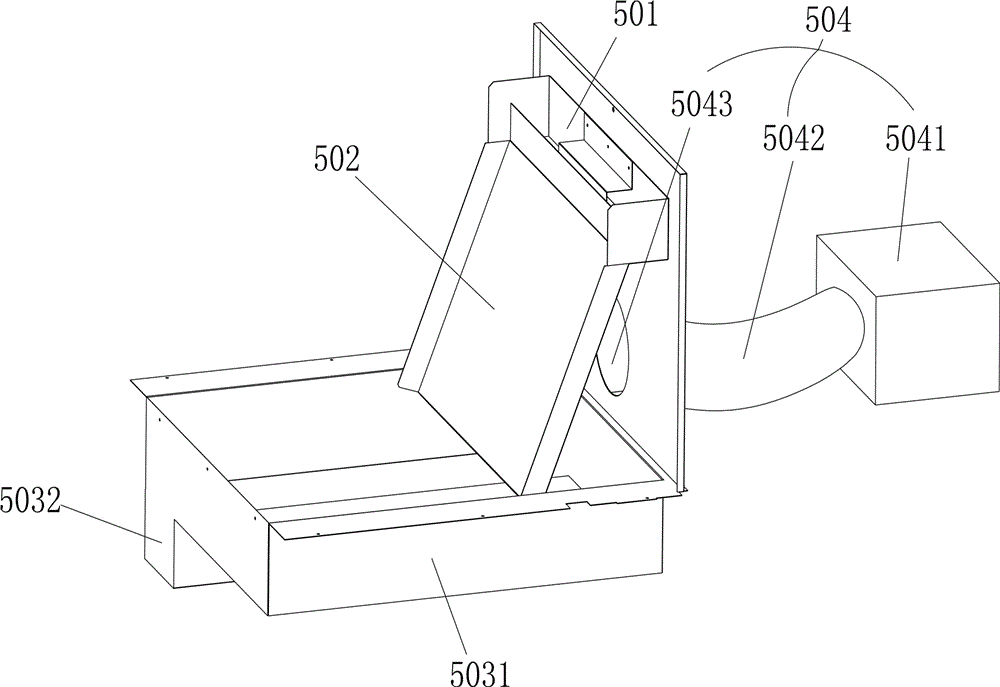

Die oil-blowout mechanism and stamping die thereof

ActiveCN107214257ASimple structureRealize automatic fuel injectionShaping toolsMotor driveGear drive

The invention discloses a die oil-blowout mechanism and a stamping die thereof. The die oil-blowout mechanism comprises a mounting table, an oil-blowout support, a transmission device and a motor. The transmission device comprises a rack, a compound gear and a transition gear set, the compound gear comprises an upper layer gear, a lower layer gear and a connecting shaft, and the connecting shaft connects the upper layer gear with the lower layer gear; and the upper layer gear is connected with the rack in an engaged mode, and the lower layer gear is connected with the transition gear set in an engaged mode. The motor drives the compound gear to rotate in the using process, the compound gear drives the rack and the transition gear set to move and drives the oil-blowout support to move, after the position is reached, drawing oil is blown out, and automatic oil-blowout is achieved. After the automatic oil-blowout is completed, the motor reversely drives the compound gear to rotate, and the oil-blowout support is driven to return back to the original position. According to the die oil-blowout mechanism, the structure is simple, automatic oil-blowout can be achieved, and the oil-blowout efficiency is improved. The invention further provides a stamping die including the die oil-blowout mechanism, the problem that oil needs to be smeared on workpieces manually is solved, and the quality of the stamped workpieces is improved.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

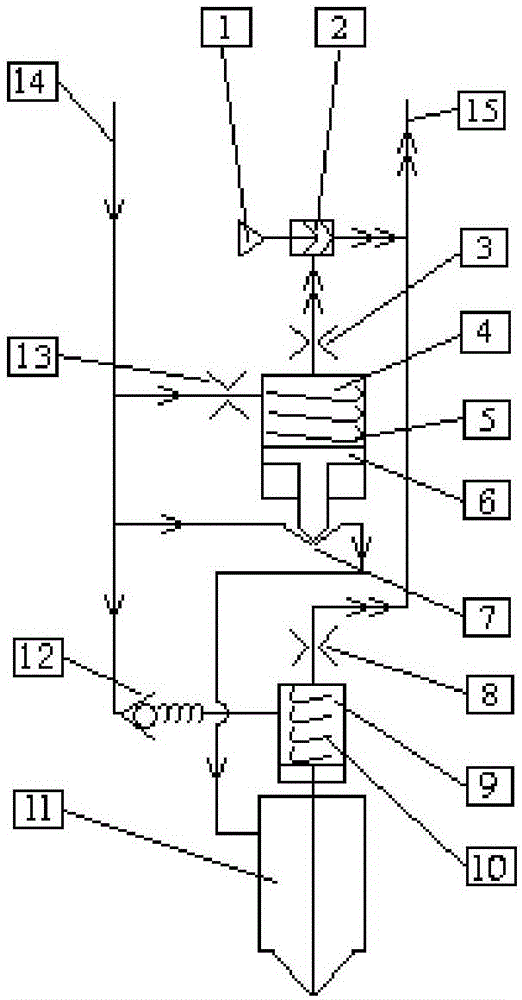

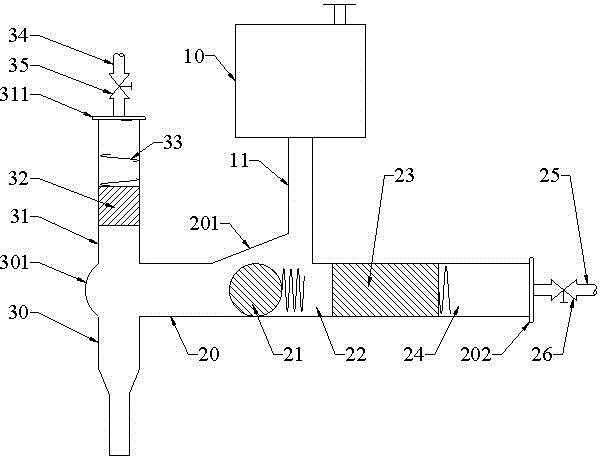

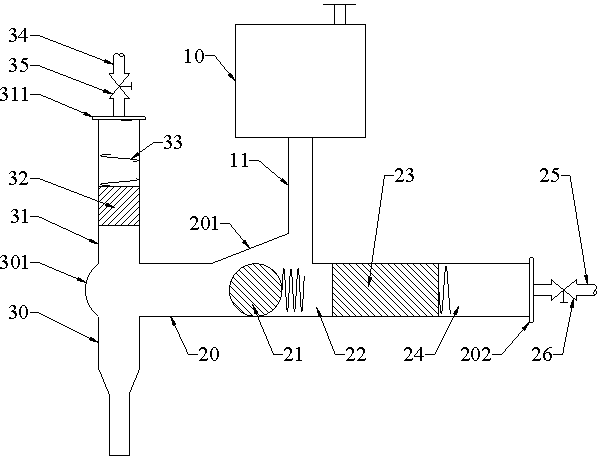

Oil injection system facilitating adjustment of oil injection state

InactiveCN105089890AAvoid elevationReduce cloggingFuel injection apparatusMachines/enginesPressure sensorValve seat

The invention discloses an oil injection system facilitating adjustment of the oil injection state. An iron core is arranged in an oil injector and sleeved with an electromagnetic coil. The oil injector is connected with a limiting sleeve. A nozzle sleeve is arranged in the limiting sleeve. The outer wall of the nozzle sleeve is sleeved with a first sealing ring. A valve seat is arranged in the limiting sleeve. The valve seat is connected with a valve plate. A second pressure sensor and a second temperature sensor are arranged in the oil injector. The oil injector is provided with an installation sleeve. A protecting sleeve is arranged in the installation sleeve. A pressure-adjusting sliding block is arranged in the protecting sleeve. The pressure-adjusting sliding block is connected with a spring. The spring penetrates an opening of the protecting sleeve to be connected with the valve plate. A first pressure sensor and a first temperature sensor are arranged in the protecting sleeve. By means of the system, internal operating conditions of the oil injector can be known, and some small potential problems can be solved in time and prevented from getting worse; and the probability of blockage occurring in the oil injection process is reduced, the oil injection efficiency is improved, and the use cycle is prolonged.

Owner:四川膨旭科技有限公司

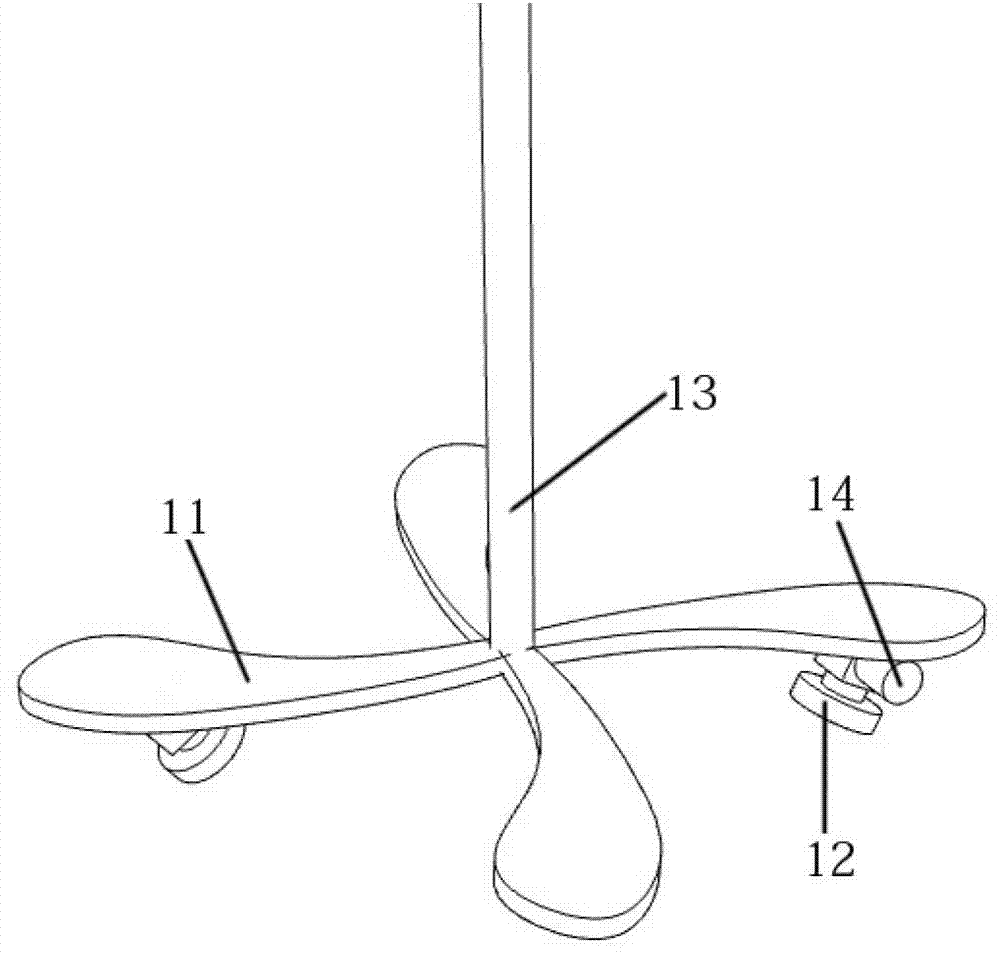

Oil-injecting device and oil-injecting method for cake molds

The invention discloses an oil-injecting device and an oil-injecting method for cake molds. The oil-injecting device comprises a rotating shaft, rotating pieces, more than two nozzles and a hollow box-shaped oil-injecting tank. The rotating pieces are connected on the lower portion of the rotating shaft, and the nozzles are fixed on the lower portion of the rotating pieces. The axis of each nozzle and the rotating shaft are intersected at one point. The rotating shaft drives the rotating pieces to rotate back and forth. The intersection point of the axis of each nozzle is higher than the plane of a to-be-oil-injected cake mold. The inner portion of the oil-injecting tank is divided into an upper maintenance chamber and a lower working chamber by a partition. An oil-injecting hole is reserved on the partition, and the rotating pieces are arranged in the oil-injecting hole. An opening is arranged in the front face of the working room. A pipeline is arranged at the top of the oil-injecting tank. Oil-injecting efficiency is improved and oil-injecting quality is guaranteed. The oil-injecting device is convenient to operate, easy to use, simple to maintain, simple in structure and low in cost. Costs of enterprises using the oil-injecting device and the oil-injecting method are greatly reduced. High quality of cakes produced by the enterprises can be guaranteed while production efficiency is improved.

Owner:遵义市老谢氏鸡蛋糕食品厂

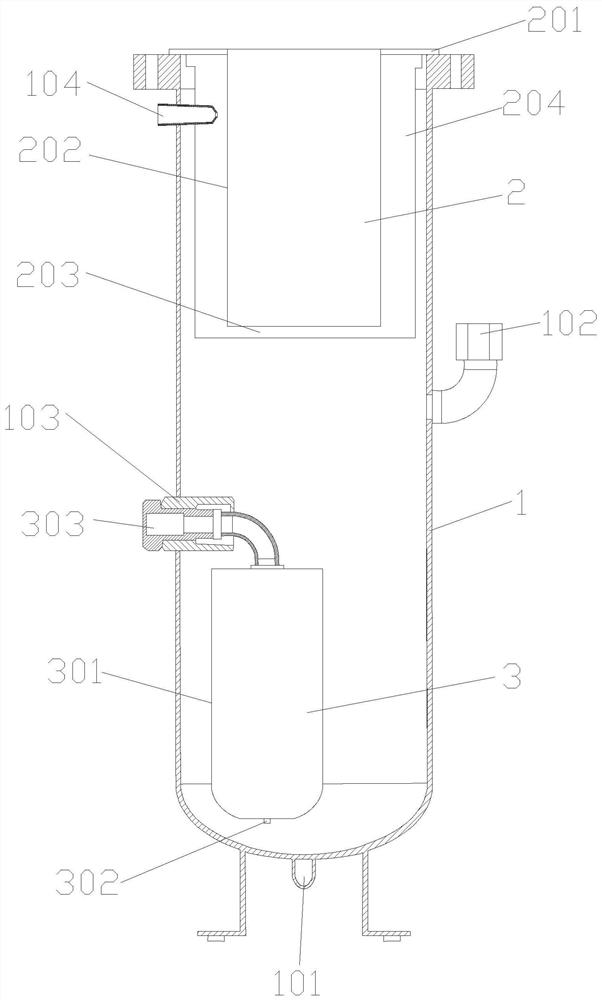

Universal multi-model oil separation barrel integration device for screw compressor

PendingCN113550906AAvoid Cooler BlockageAvoid fuel injection efficiencyRotary piston pumpsRotary piston liquid enginesOil separationGas separation

The invention discloses a universal multi-model oil separation barrel integration device for a screw compressor. The universal multi-model oil separation barrel integration device is provided with an oil-gas separation barrel, an oil-gas separator and an engine oil filter are arranged in the oil-gas separation barrel, a compressed oil-gas inlet is formed in the upper end of the side wall of a barrel body of the oil-gas separation barrel, a compressed air outlet is formed in a barrel cover of the oil-gas separation barrel, and an oil drainage hole is formed in the lower end of the barrel body of the oil-gas separation barrel; the oil-gas separator comprises a fixed flange, a first-stage oil crude separation barrel at the lower end of the fixed flange and a second-stage oil separation net at the bottom of the first-stage oil crude separation barrel; a centrifugal channel is formed between the first-stage oil crude separation barrel and the inner wall of a barrel body of the oil-gas separation barrel for separation, and then separation is performed again through a third extremely fine separation core; and the engine oil filter comprises a filter body, an engine oil inlet at the lower end of the filter body, an engine oil filter screen in an inner cavity of the filter body and a clean engine oil outlet at the upper end of the filter body. The engine oil filter of the device directly filters out impurities and particulate matters at the foremost end, and then the engine oil directly enters the cooler to be cooled, and then enters the machine head of the compressor.

Owner:王伯全

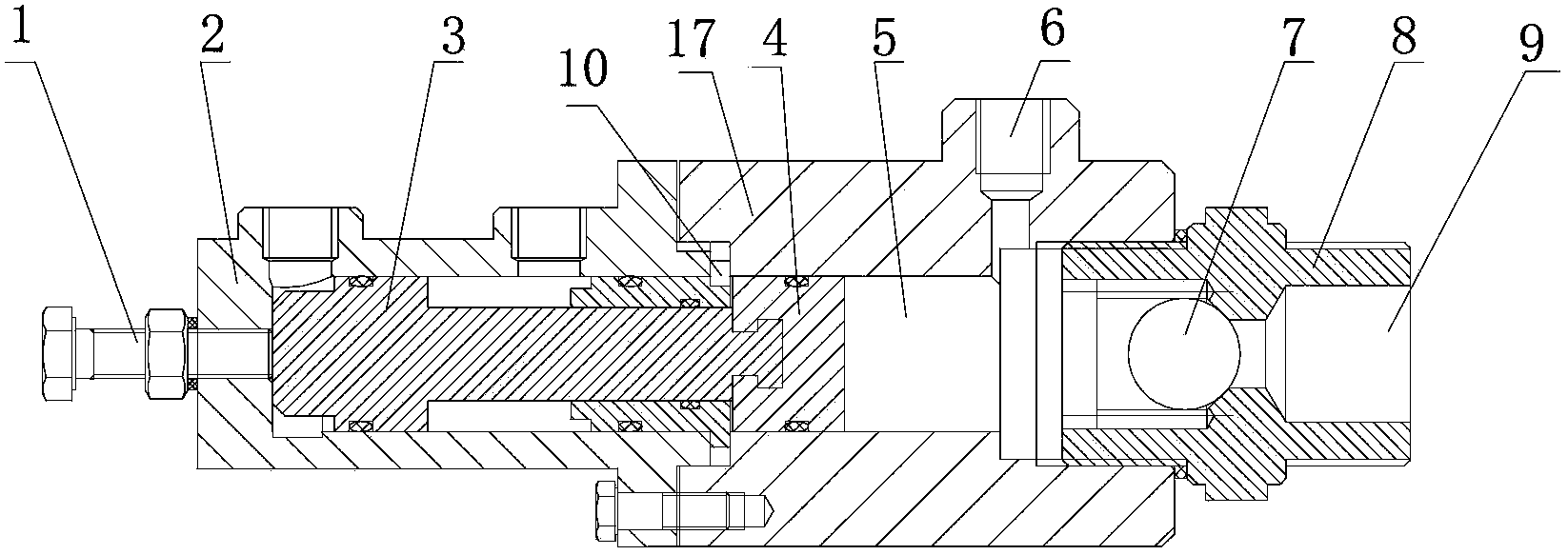

Automatic thread compound spraying device

ActiveCN103537393AReduce labor costsImprove fuel injection efficiencyLiquid spraying apparatusEngineeringSteel ball

The invention provides an automatic thread compound spraying device. The automatic thread compound spraying device comprises a first cylinder body and a second cylinder body matched with the first cylinder body. A first piston rod is arranged inside the first cylinder body, a thread cavity is formed inside the second cylinder body, a piston matched with the first piston rod is arranged inside the thread cavity, the other end of the first piston rod is connected with an adjusting rod, the tail end of the thread cavity is provided with a steel ball which is arranged inside a thread compound inlet, one side of the thread cavity is provided with a thread compound outlet which is communicated with an inner cavity of a second piston rod inside a third cylinder body, and the outlet end of the second piston rod is provided with a thread compound spraying needle. According to the automatic thread compound spraying device, the structure of the thread compound spraying device is ingeniously designed, full-automatic thread compound spraying is achieved through an external switch which is electrically connected, labor cost is saved, and thread compound spraying efficiency is improved. The thread compound inlet quantity is adjusted through the adjusting rod, the waste of the thread compound cannot be caused, and the utilization ratio of the thread compound is improved.

Owner:江苏地龙重型机械有限公司

Oil spraying device of special coating machine for metallized film

InactiveCN106086780APrevent oil spillsShort injection efficiencyVacuum evaporation coatingSputtering coatingBottleAtmospheric pressure

The invention relates to an oil spraying device of a special coating machine for a metallized film. The oil spraying device comprises an oil bottle, an oil outlet tube, a horizontally-arranged oil control tube and a spray head; the top of the oil control tube is provided with a conical chamber, the tail end of the oil control tube is provided with a first cover plate, and the oil control tube is internally provided with a bead, a first spring, a first piston and a second spring; and the outer part of the first cover plate is provided with a first air inlet tube on which a first air valve is arranged. According to the oil spraying device of the special coating machine for the metallized film, the opening between the bead and the oil control tube is controlled by virtue of air pressure so that oil leakage of the oil spraying device is avoided; and then, the motion of a second piston is controlled by virtue of air pressure to carry out pressurization treatment on coating oil entering the spray head, so that the coating oil sprayed from the head part of the spray head has enough spraying speed and pressure, the oil spraying time is shortened, and the oil spraying efficiency and quality are improved. The oil spraying device is simple in structure, convenient to use, stable in operation, short in oil spraying time, high in oil spraying efficiency and good in oil spraying effect.

Owner:铜陵市铜创电子科技有限公司

Truss type oiling machine

InactiveCN106182396AExquisite structureEasy to operateLiquid surface applicatorsAuxillary shaping apparatusHazardous substanceFuel tank

The invention discloses a truss type oiling machine which comprises a portal frame, a roller and an oil spraying tube, wherein the roller is arranged between two sides of the portal frame; vertical kidney-shaped holes are formed in two sides of the portal frame; springs are arranged in the kidney-shaped holes; two sides of the roller are arranged below the springs; a detecting probe is arranged on one side of each of the kidney-shaped holes; the lower edge of the portal frame is the same as that of the roller in height; the oil spraying tube is arranged below the portal frame; fuel spray nozzles are arranged at the lower part of the oil spraying tube; a fuel tank is arranged on the portal frame; a pressure pump is arranged on the oil spraying tube; and the oil spraying tube is arranged above one side of the roller. The truss type oiling machine is exquisite in structure and convenient to operate, can ensure coating quality, improves oil spraying efficiency, reduces the probability that a worker is in direct contact with a hazardous substance, and alleviates pollution.

Owner:JIANGSU JINMAO TECH DEV

Oil-way oil supply system used in direct injection engine

InactiveCN106812642AAvoid elevationReduce cloggingMachines/enginesSpecial fuel injection apparatusSpray nozzlePressure sensor

The invention discloses an oil supply system for a direct-injection engine. An iron core is arranged in the fuel injector body, and an electromagnetic coil is sleeved on the iron core. A nozzle cover is provided, a sealing ring 1 is sleeved on the outer wall of the nozzle cover, a valve seat is provided in the limit sleeve, the valve seat is connected to a valve plate, and a second pressure sensor and a second temperature sensor are provided in the injector body; The fuel injector is provided with a mounting sleeve, a protective sleeve is provided in the mounting sleeve, a pressure regulating slider is provided in the protective sleeve, a spring is connected to the pressure regulating slider, and the spring passes through the opening of the protective sleeve to connect with the valve plate, and the protective sleeve is provided with a There is a first pressure sensor and a first temperature sensor. The system can understand the internal operating conditions of the fuel injector, and can deal with some potential minor problems in time to prevent them from expanding. It also reduces the probability of clogging during the fuel injection process, improves fuel injection efficiency, and prolongs the service life.

Owner:重庆汇阁仕汽车信息咨询服务有限公司

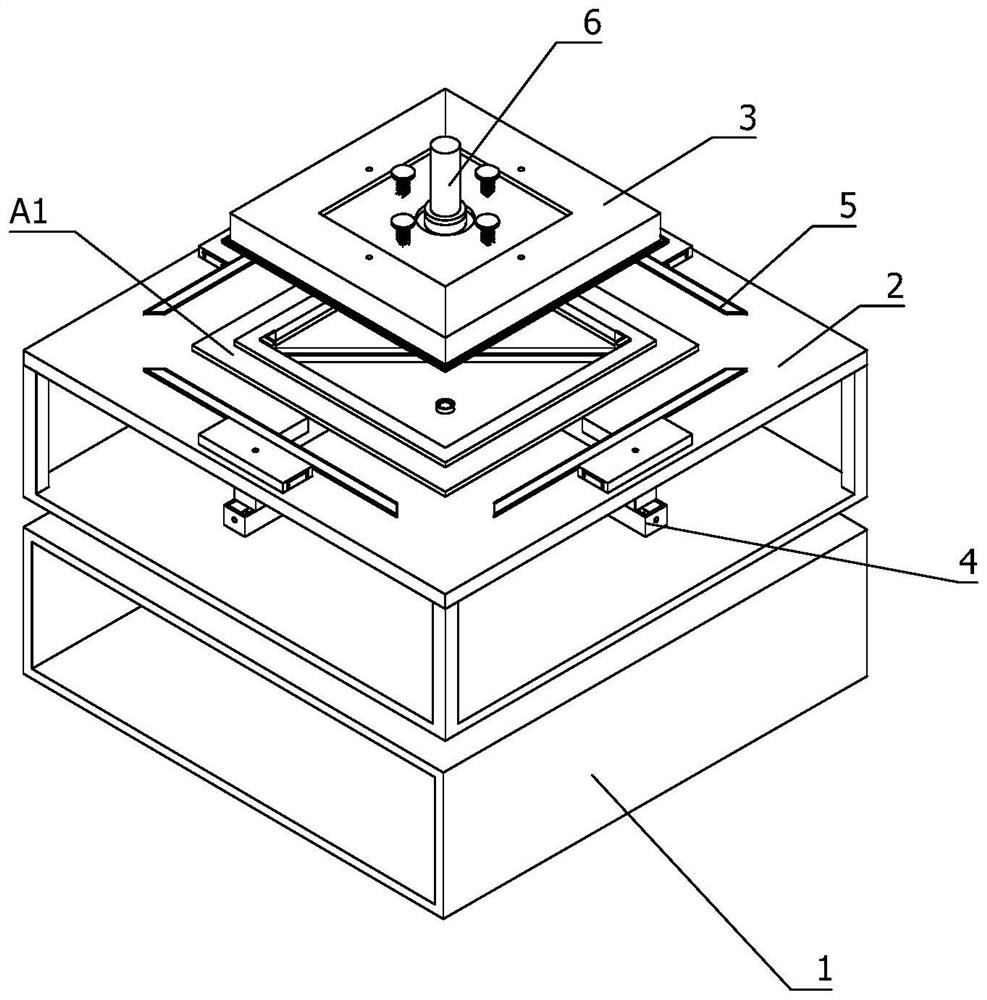

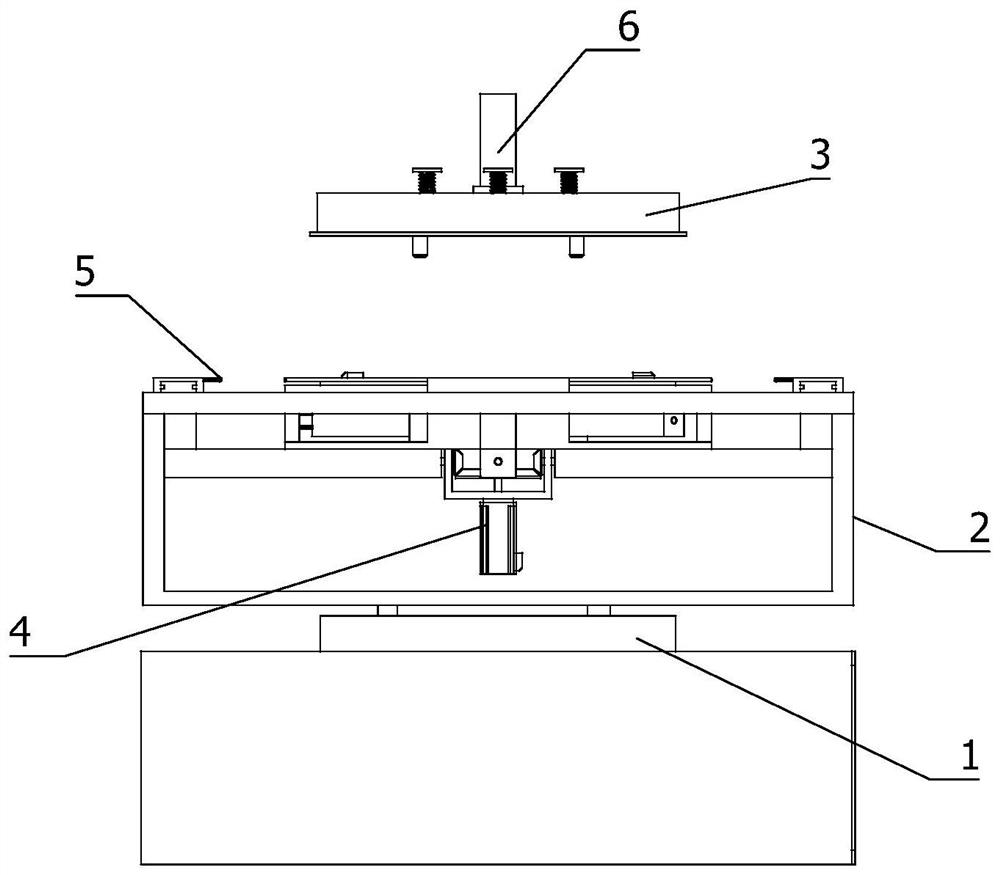

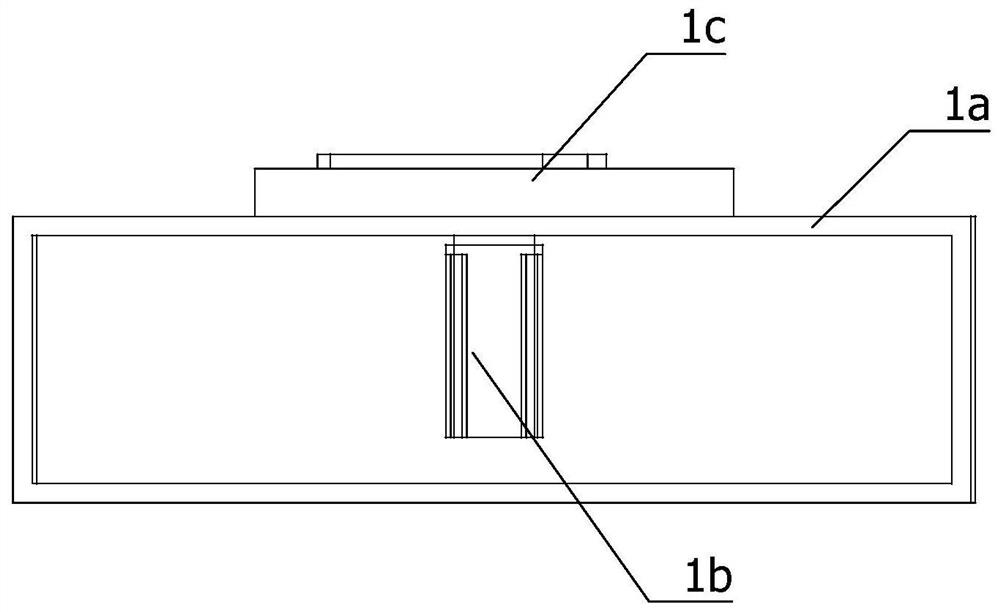

A stamping die cleaning machine

ActiveCN104858179BEasy to collectGuaranteed cleanlinessShaping toolsDirt cleaningPunchingEconomic benefits

The invention relates to the technical field of mechanical devices, in particular to a sweeping machine of a punching die. The sweeping machine comprises a machine frame, a control mechanism, an oil supply mechanism, a displacement mechanism, a material suction mechanism and a sweeping mechanism. The control mechanism, the oil supply mechanism and the displacement mechanism are fixedly connected with the machine frame. The sweeping mechanism is fixedly connected with the displacement mechanism. The material suction mechanism is arranged on one side of the machine frame. The oil supply mechanism is communicated with the sweeping mechanism through an oil pipe. The material suction mechanism is communicated with the sweeping mechanism through a pipeline. By means of the sweeping machine, sweeping and oil spraying can be automatically conducted on the punching die, the sweeping efficiency is high, the oil spraying efficiency is high, the sweeping effect is good, the oil spraying effect is good, labor is saved, dust, iron residues and waste materials can not fly, the cleanliness of workshops is kept, health of people is ensured, collection and recycle of the iron residues and the waste materials are facilitated, energy conservation and emission reduction are achieved, and economic benefits are improved.

Owner:湖南沁峰机器人有限公司

Oil injector for diesel engine

InactiveCN103225577ASimple structureEasy to installFuel injection apparatusMachines/enginesHigh pressureDiesel engine

The invention discloses an oil injector for a diesel engine. The oil injector comprises an oil injector body, wherein an oil injection channel is mounted inside the oil injector body; an inlet pipeline of the oil injection channel is horizontally arranged; an outlet pipeline of the oil injection channel is vertically arranged; a filter screen is arranged at an inlet end of the oil injection channel; an outlet end of the oil injection channel is connected with a needle valve; an ejector rod is connected onto the needle valve; and a pressure adjusting spring is fixedly mounted on the ejector rod. In the manner, the oil injector for the diesel engine is simple in structure, and can be mounted reliably, improve the oil injection efficiency, reduce oil leakage, purify high pressure oil, filter impurities, and guarantee the cleanliness of the oil inside the oil injection channel.

Owner:史立新

Oil sprayer with quick drying function

PendingCN112076933AAffects corrosion resistanceImprove fuel injection efficiencyPretreated surfacesCoatingsSprayerAir pump

The invention discloses an oil sprayer with a quick drying function. The oil sprayer comprises a mounting support, a collecting bin is mounted in the middle of the top of the mounting support, the bottom end of the collecting bin communicates with a liquid discharging pipe, an electromagnetic valve is arranged on the inner side of the liquid discharging pipe, a mounting bin is mounted at one end of the top of the mounting support, a spraying bin is mounted at the top of the collecting bin, a liquid storage bin is mounted at the end, close to the mounting bin, inside the spraying bin, and a mounting block is mounted at the top of the liquid storage bin. The oil sprayer is provided with a heating bin, a heater, an air pump, an air inlet pipe, an air outlet pipe and an air outlet, the heatercontinuously heats air in the heating bin, the air pump pumps out hot air through the air inlet pipe, and performs accelerated drying on sprayed automobile parts through the air outlet pipe and the air outlet, drying treatment is conducted through hot air blowing, so that the drying efficiency of the automobile parts is improved, and the consumed time is shortened, and then the consumed time for machining the automobile parts is shortened.

Owner:广德中晨电子科技有限公司

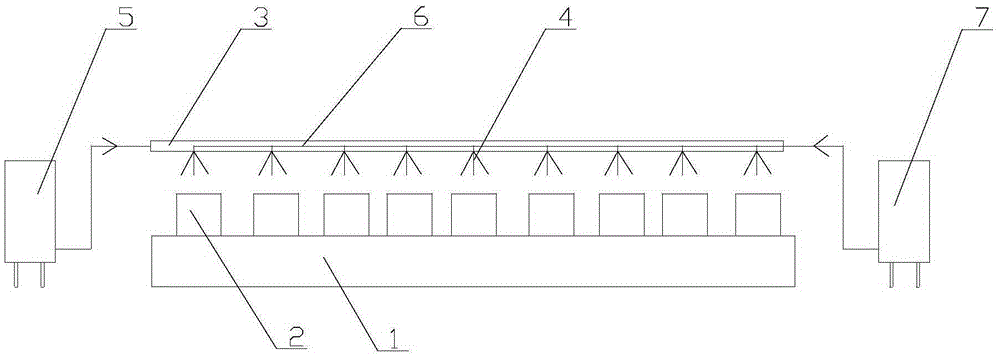

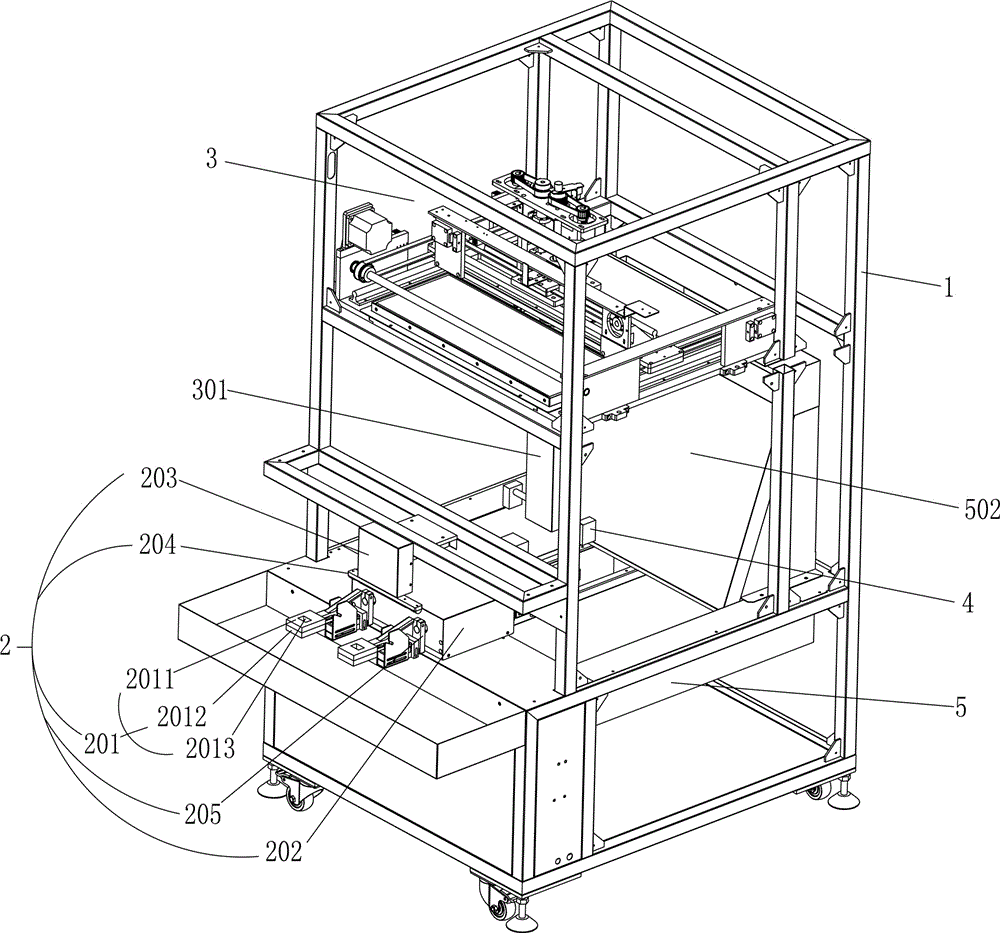

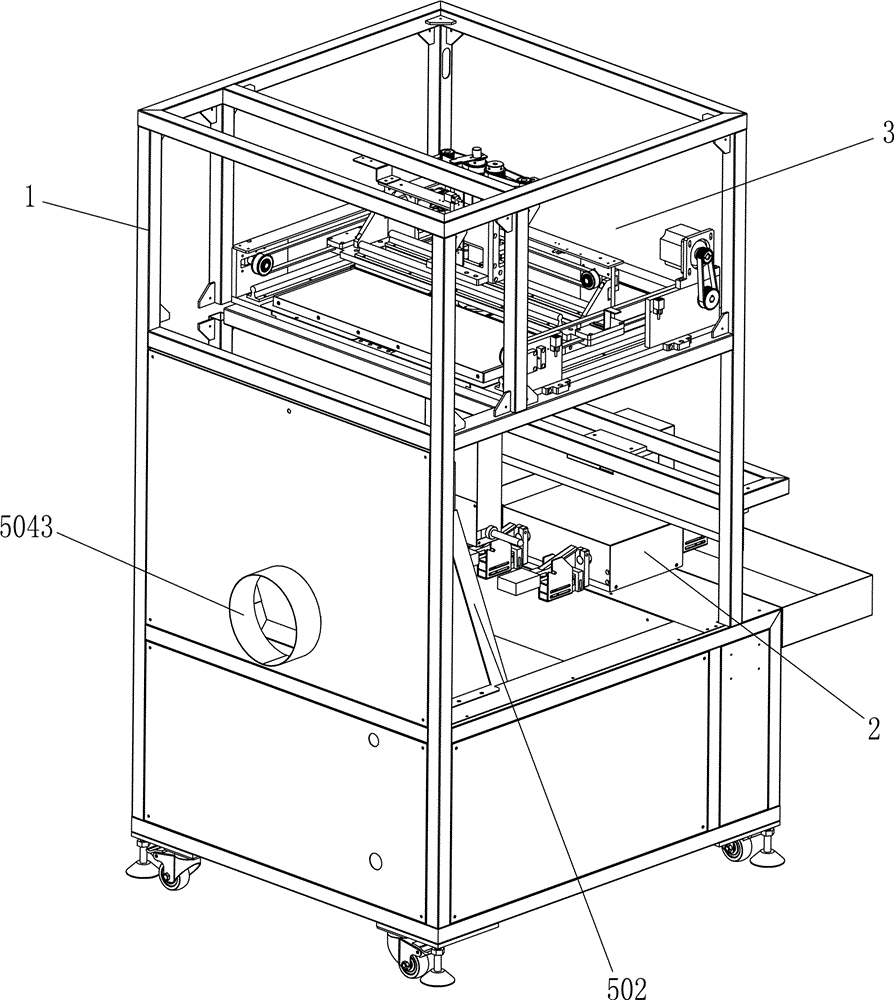

Oil injection equipment and oil injection process for engine cylinder sleeves

InactiveCN105289879ARealize automatic fuel injectionImprove fuel injection efficiencyLiquid surface applicatorsLiquid spraying apparatusInjector nozzleInjection equipment

The invention provides oil injection equipment and oil injection process for engine cylinder sleeves. The oil injection equipment comprises a cylinder sleeve containing table. The cylinder sleeves are sequentially and vertically placed on the cylinder sleeve containing table. An oil pipe is arranged on the cylinder sleeve containing table. The lower portion of the oil pipe is connected with oil injection nozzles through pipelines. The oil injection nozzles are arranged at the top ends of the cylinder sleeves in a one-to-one correspondence manner. One end of the oil pipe is connected to an oil drum. An air guide pipe is further arranged in the oil pipe, communicated with the oil injection nozzles, and used for providing air pressure for oil injection of the oil injection nozzles. One end of the air guide pipe is connected to an air compressor. The oil injection process includes the steps such as control over the flow of the oil injection nozzles. A pneumatic system is used for automatic oil injection on the cylinder sleeves, and the oil injection equipment and the oil injection process have the beneficial effects of being high in oil injection efficiency, convenient to control and large in handling capacity.

Owner:ZYNP GRP ANHUI CO LTD

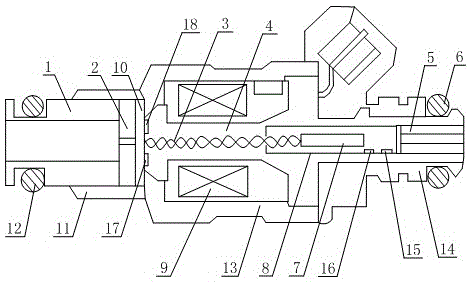

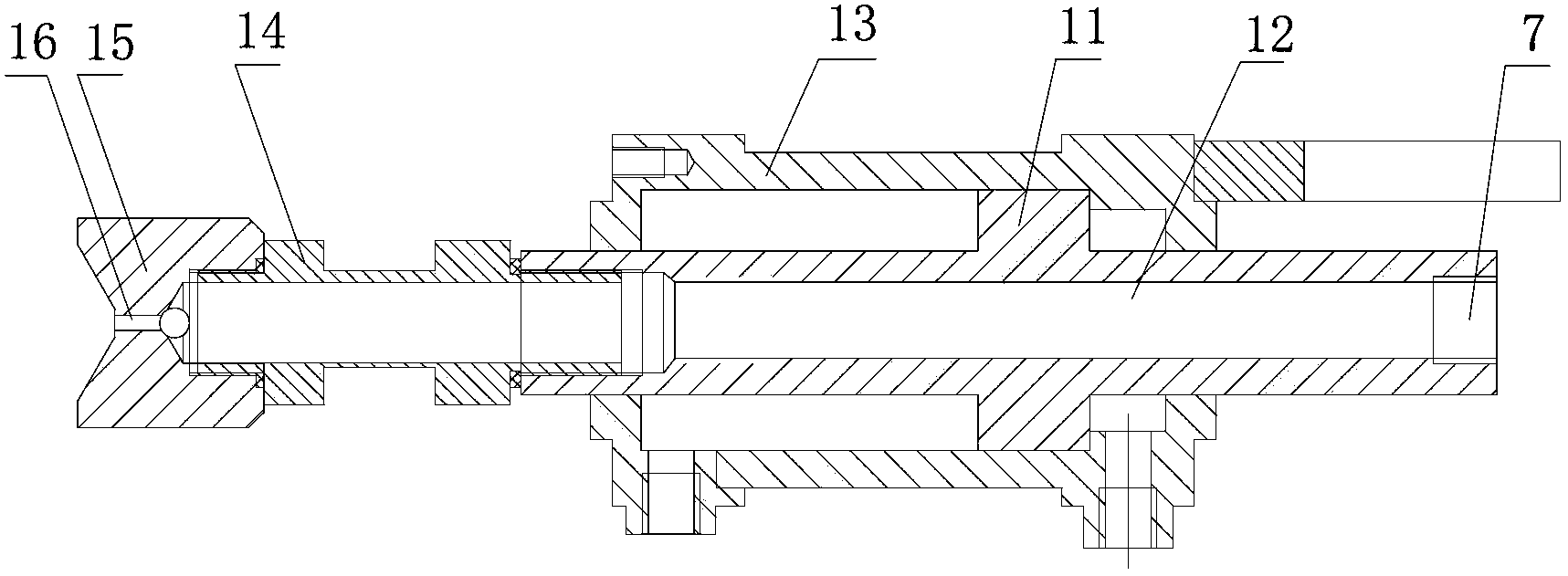

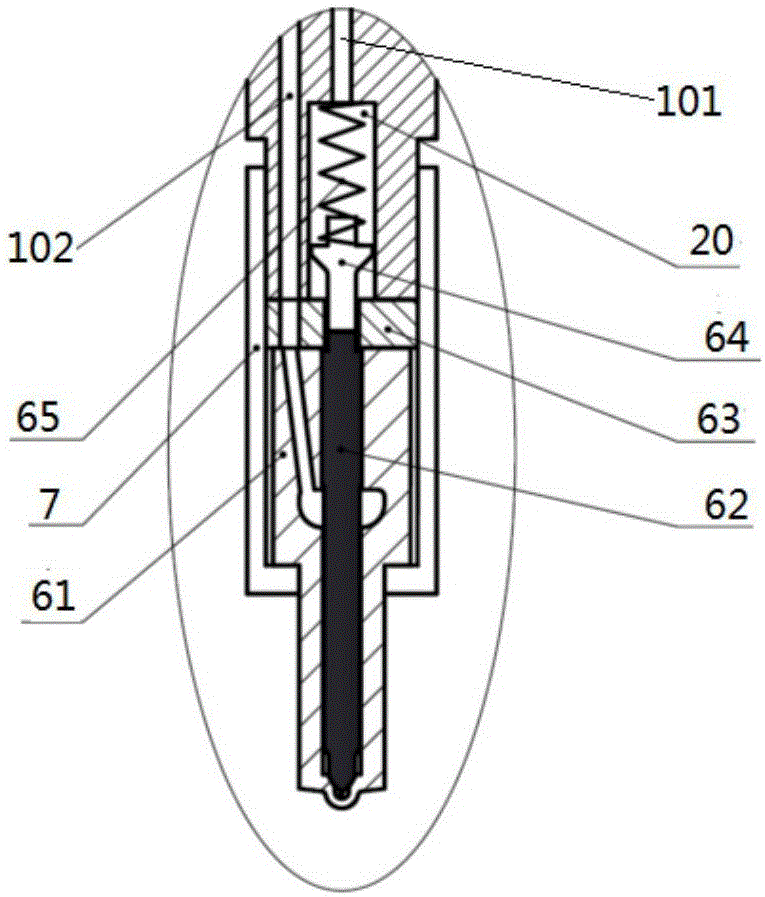

Micro-injection electronically-controlled fuel injector with pressure-maintaining structure

ActiveCN107524551AAccelerate the pressure build rateIncrease open rateFuel injection apparatusMachines/enginesInlet channelEngineering

The invention relates to a micro-injection electronically-controlled fuel injector with a pressure-maintaining structure. According to the micro-injection electronically-controlled fuel injector, an upper fuel cavity as well as a main fuel inlet channel, a main fuel return channel, a fuel inlet channel and a fuel return channel which communicate with the upper fuel cavity are formed in the upper body of the fuel injector; the lower body of the fuel injector is connected to the lower end of the upper body of the fuel injector through a fuel injector fastening nut, a lower fuel cavity is formed in the lower body of the fuel injector, and the lower fuel cavity communicates with the main fuel return channel; a nozzle member is connected to the lower end of the lower body of the fuel injector through a nozzle fastening nut and communicates with the lower fuel cavity, and further communicates with a main fuel channel penetrating through the lower body of the fuel injector; and an electromagnetic valve is connected to the left side of the upper part of the upper body of the fuel injector through an electromagnetic valve fastening nut, one end part of a control valve element of the electromagnetic valve stretches in the upper fuel cavity, and the other end part of the control valve element is abutted against an electromagnetic valve return spring arranged at the central part of an electromagnet. According to the micro-injection electronically-controlled fuel injector disclosed by the invention, a fuel inlet process and a fuel return process can be mutually independent, so that the influence of the mutual interference of fuel flowing in the fuel inlet process and the fuel return process on a fuel injection process is avoided; and the opening speed of a needle valve can be increased, so that the injection characteristic of a micro-injection fuel system is improved.

Owner:CHONGQING HONGJIANG MACHINERY

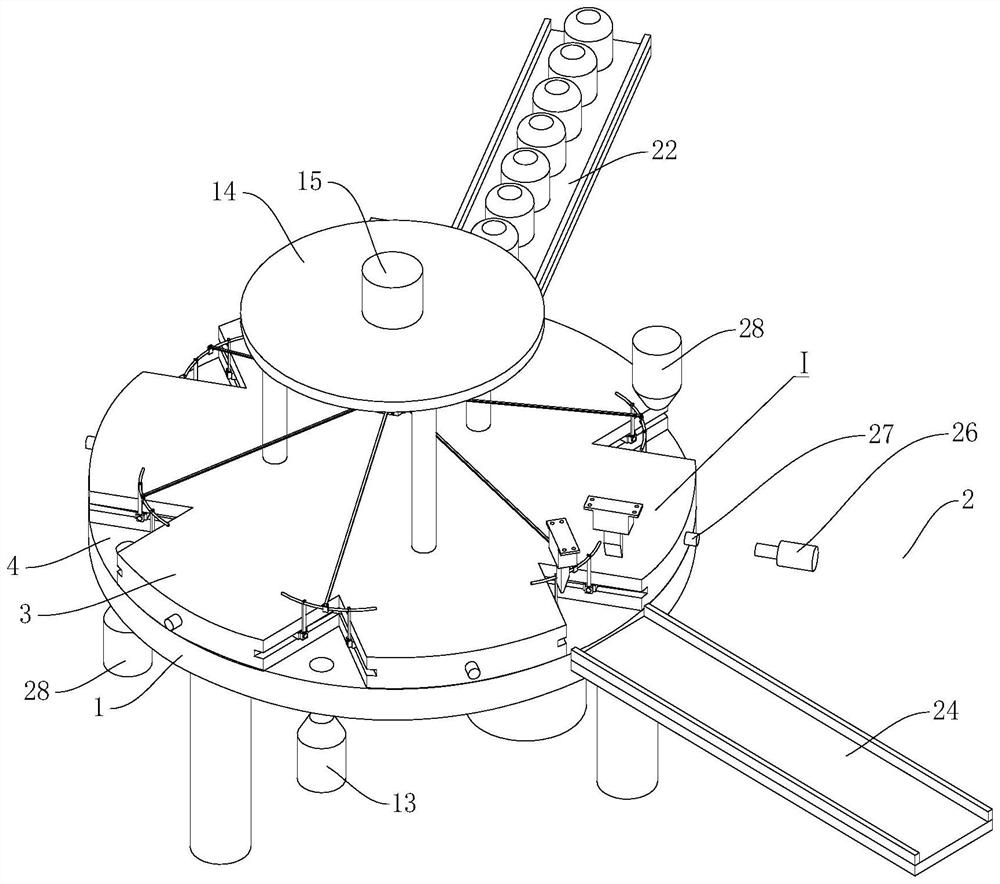

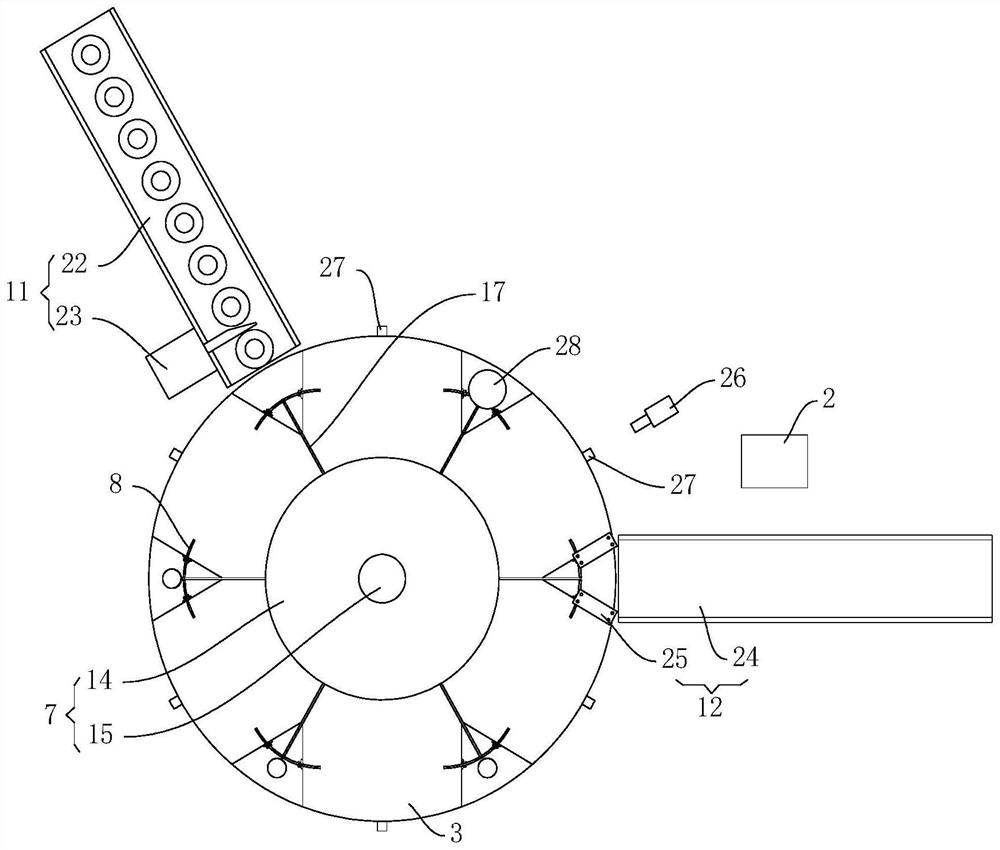

Full-automatic feeding and discharging rotating disc type oil spraying machine

ActiveCN114713408AShorten the timeImprove fuel injection efficiencySpraying apparatusInjector nozzleSprayer

The invention relates to the technical field of oil sprayers, and provides a full-automatic feeding and discharging rotating disc type oil sprayer which comprises a rack. A controller; the rotary table is rotationally arranged on the rack and provided with a V-shaped groove, and a sliding groove is formed in the inner wall of the V-shaped groove. The sliding block is slidably arranged in the sliding groove. The magnet is arranged on the sliding block and is used for adsorbing the shell; the adjusting mechanism is arranged on the rotary table and provided with a traction rod, and the traction rod pushes the sliding block to change the position of the sliding block. One end of the rotating shaft is fixedly connected with the rotary table; the driving mechanism is electrically connected with the controller and is provided with a rotating output end which is connected with the other end of the rotating shaft; the feeding mechanism is electrically connected with the controller and used for pushing a shell to be subjected to oil injection into the V-shaped groove. The discharging mechanism is electrically connected with the controller. The oil nozzle is arranged on the rack; the sensing assembly is electrically connected with the controller. According to the technical scheme, the problem that a plurality of sets of molds can not be used on the premise that a shell is not thrown out of a rotating disc type oil spraying machine in the prior art is solved.

Owner:河北钛通滤清器有限公司

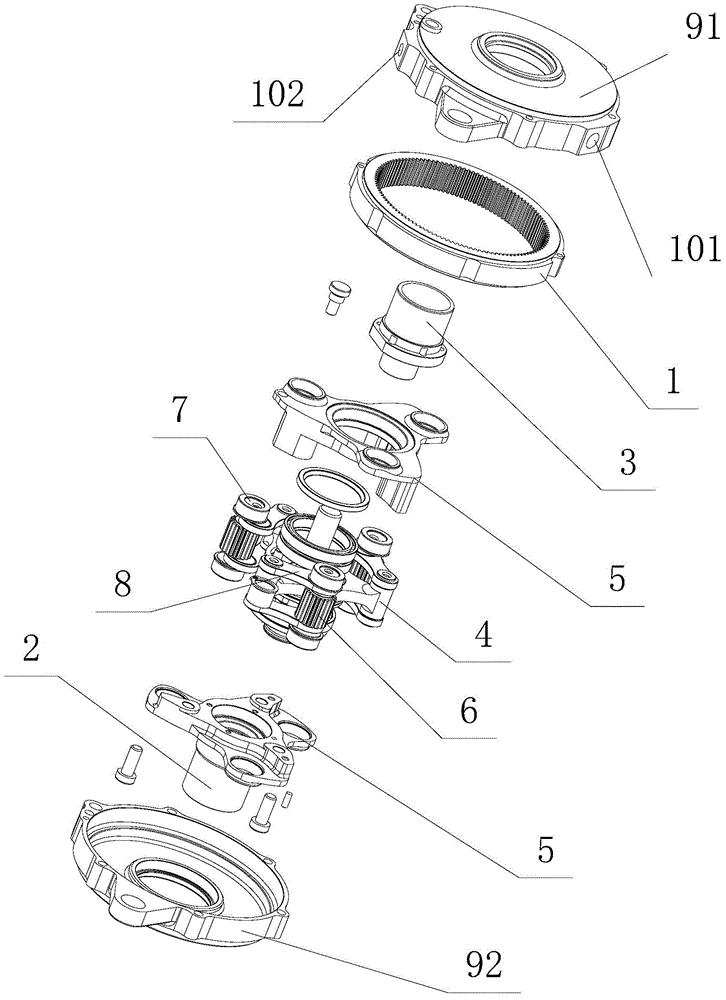

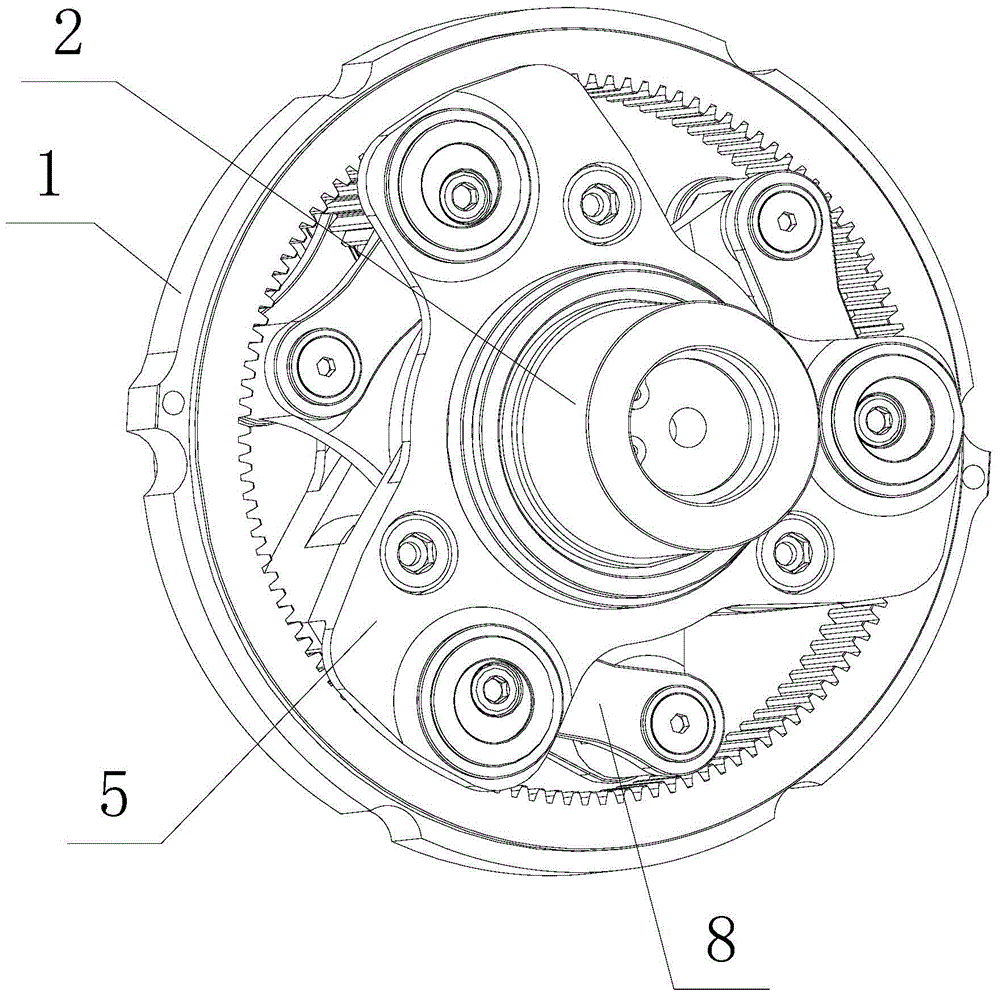

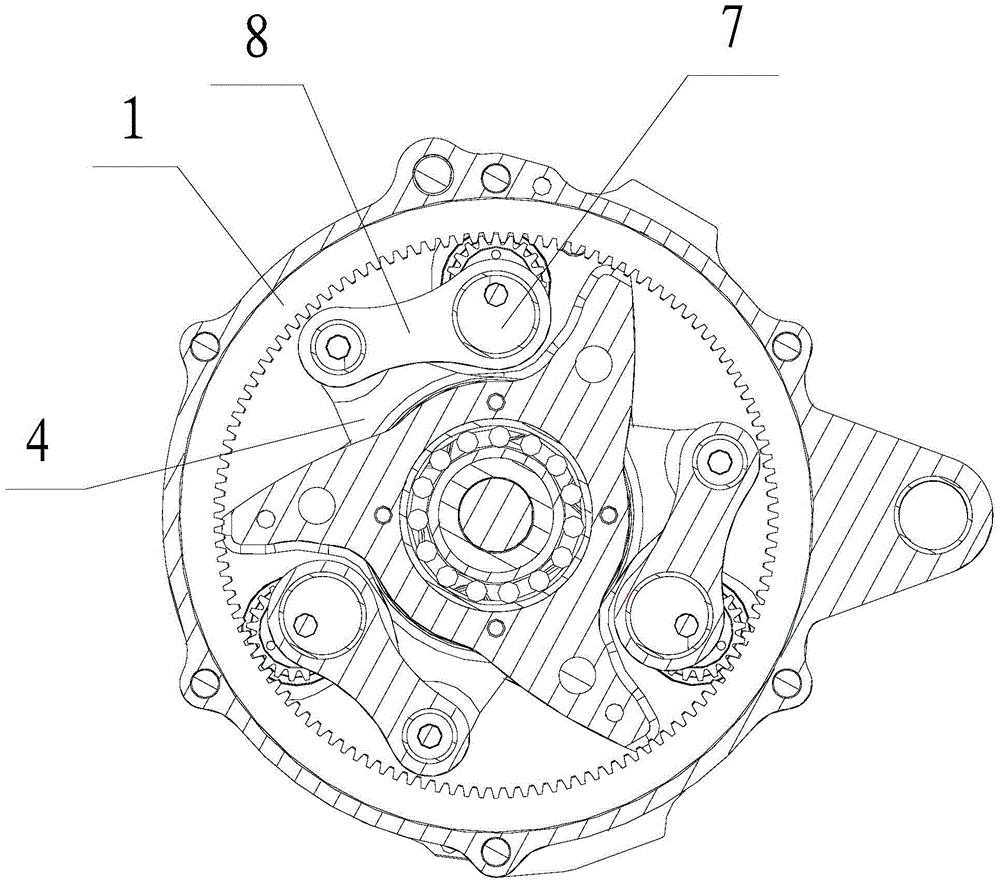

Phase difference transmission system of engine fuel injection pump

InactiveCN103603759BIncrease output powerIncrease burn rateMachines/enginesFuel injecting pumpsCombustionPhase difference

The invention provides a phase difference transmission system of an engine fuel injection pump. The phase difference transmission system used for controlling the fuel injection time of the fuel injection pump comprises a shell, a clutch flange, a spindle adapter, a spindle flange, a planet gear rack, an eccentric wheel and a connecting rod. A planet gear mechanism is disposed on the clutch flange. An eccentric mechanism is disposed between the planet gear mechanism and the spindle adapter. The ratio of the tooth number of an inner tooth gear ring to that of a planet gear is n which equals to the number of the cylinder bodies of the fuel injection pump. By the phase difference transmission system mounted between the power input end and the cam shaft of the fuel injection pump, the fuel injection efficiency of the fuel injection pump can be controlled, fuel combustion rate of the engine is then increased, emission and pollution are reduced, and the output power of the engine is increased.

Owner:宁波富莱茵汽车部件有限公司

Oil injection device of special coating machine for metallized thin film

InactiveCN106086780BPrevent oil spillsShort injection efficiencyVacuum evaporation coatingSputtering coatingBottleAtmospheric pressure

The invention relates to an oil spraying device of a special coating machine for a metallized film. The oil spraying device comprises an oil bottle, an oil outlet tube, a horizontally-arranged oil control tube and a spray head; the top of the oil control tube is provided with a conical chamber, the tail end of the oil control tube is provided with a first cover plate, and the oil control tube is internally provided with a bead, a first spring, a first piston and a second spring; and the outer part of the first cover plate is provided with a first air inlet tube on which a first air valve is arranged. According to the oil spraying device of the special coating machine for the metallized film, the opening between the bead and the oil control tube is controlled by virtue of air pressure so that oil leakage of the oil spraying device is avoided; and then, the motion of a second piston is controlled by virtue of air pressure to carry out pressurization treatment on coating oil entering the spray head, so that the coating oil sprayed from the head part of the spray head has enough spraying speed and pressure, the oil spraying time is shortened, and the oil spraying efficiency and quality are improved. The oil spraying device is simple in structure, convenient to use, stable in operation, short in oil spraying time, high in oil spraying efficiency and good in oil spraying effect.

Owner:铜陵市铜创电子科技有限公司

Automatic oil spraying machine

InactiveCN106622786AStrong structural reliabilityIncrease productivityLiquid surface applicatorsSpraying apparatusDraining tubeWater source

The invention discloses an automatic oil spraying machine. The automatic oil spraying machine comprises a rack, wherein the rack is provided with a rotational positioning device, a displacement driving device, an oil spraying device, a water curtain dust collection device and an electric cabinet; a rotational driving device drives a positioning fixture to be transferred to an oil spraying station from a loading station, the loading station is arranged outside the rack, the oil spraying station is arranged inside the rack; the displacement driving device controls the oil spraying device to move to the oil spraying station from an initial position to spray oil on a workpiece on the positioning fixture; the oil spraying device is communicated with an oil storage bucket by virtue of a pipeline; and a water source enters a water containing channel from the outside, when the water containing channel is full of water, the water overflows, flows to the bottom of a water curtain along the top of the water curtain and freely flows downward from the bottom of the water curtain to form a water screen, the dust collection device is arranged at the rear of the water screen and absorbs dust produced in front of the water screen to pass through the water screen and achieve the dust filtration effect, the water screen after dust filtration is concentrated in a filter to be subjected to water filtration, and the water is filtered to be then discharged by virtue of a drainage pipe.

Owner:东莞市毅华自动化科技有限公司

Tool clamp for oil injection of plastic frame

ActiveCN114849928AEasy to sprayEffective fuel injectionSpraying apparatusEngineeringMechanical engineering

Owner:DONGGUAN YEJIA ELECTRONICS TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com