Oil-way oil supply system used in direct injection engine

A fuel supply system and engine technology, applied in the system field, can solve the problems of poor fuel injection efficiency, high maintenance cost, fuel injection nozzle blockage, etc., and achieve the effects of reducing the probability of blockage, improving fuel injection efficiency, and prolonging service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

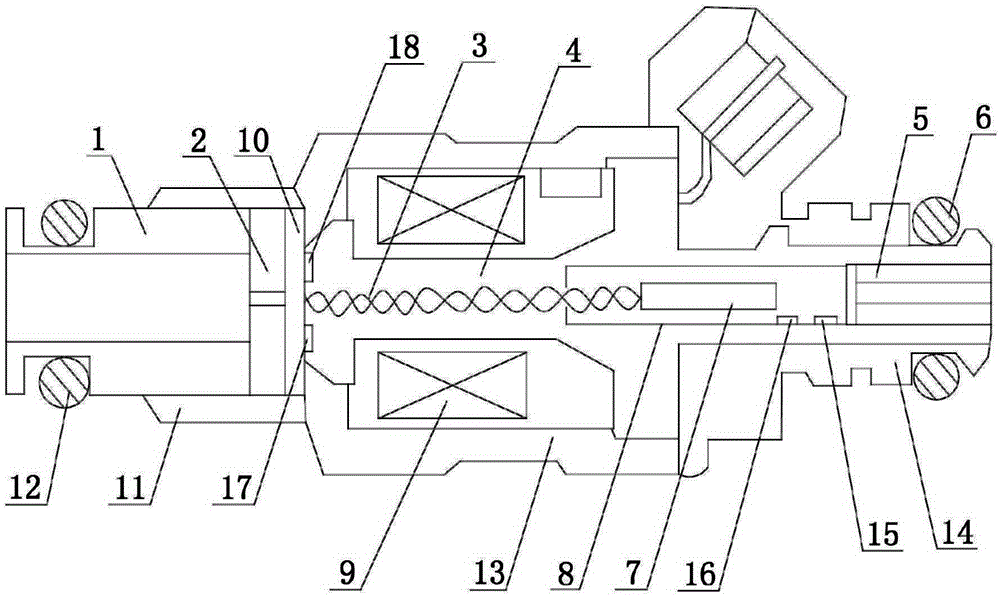

[0012] Such as figure 1 As shown, an oil supply system for a direct injection engine includes a fuel injector body 13 that is hollow inside and open at both ends, and an iron core 4 is arranged in the fuel injector body 13, and the iron core 4 The center line coincides with the center line of the injector body 13, and the outer wall of the iron core 4 is covered with an electromagnetic coil 9, and the electromagnetic coil 9 is arranged in the sealed space formed by the injector body 13 and the iron core 4, and the injector body 13 is connected to the limit sleeve 11, the opening end of the limit sleeve 11 communicates with the opening end of the injector body 13, the nozzle cover 1 is arranged in the limit sleeve 11, and the nozzle cover 1 can move horizontally in the limit sleeve 11, The outer wall of the nozzle cover 1 is sleeved with a sealing ring 12, and the sealing ring 12 can be seamlessly fitted when in contact with the inner wall of the limiting sleeve 11. The limiti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com