Oil injection equipment and oil injection process for engine cylinder sleeves

A technology for engine cylinders and cylinder liners, which is applied in the direction of injection devices, liquid injection devices, and devices for coating liquid on the surface, etc., which can solve the problems of inconvenient control and low fuel injection efficiency, and achieve high fuel injection efficiency, convenient control, and High volume effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with specific embodiment the invention is described in further detail.

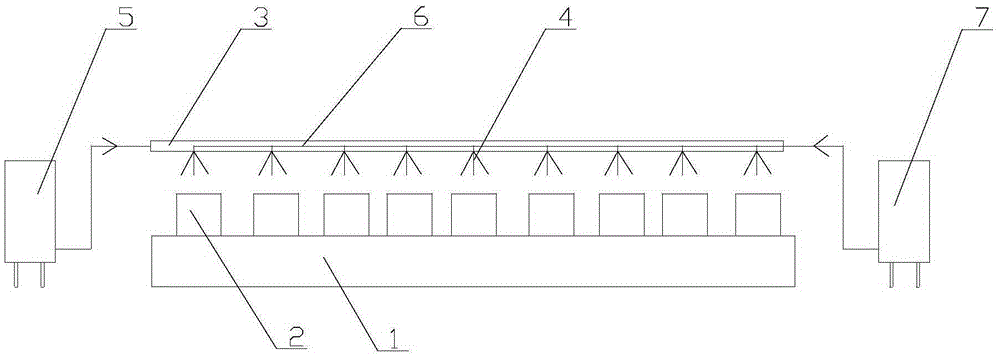

[0015] see figure 1 , a fuel injection device for engine cylinder liners, comprising a cylinder liner placement platform 1, cylinder liners 2 are placed vertically on the cylinder liner placement platform 1 in turn, and oil pipes are arranged on the cylinder liner placement platform 1 3. The lower part of the oil pipe 3 is connected with the fuel injection nozzle 4, and the fuel injection nozzle 4 is arranged on the top of each cylinder liner 2 one by one. The air guide pipe 6 communicates with each fuel injector 4 for providing air pressure for fuel injection of the fuel injector 4 , and one end of the air guide pipe 6 is connected to the air compressor 7 .

[0016] When in use, the oil flows into the oil pipe from the oil barrel 5 and gathers at the fuel injection nozzle 4. At this time, the air compressor 7 is turned on, the air guide pipe takes in air, and the fuel injecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com