Spraying system and method

A technology of spray gun and fuel injection device, which is applied in the field of spray coating system, and can solve problems such as uncontrollable oil volume and difficulty in realizing automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

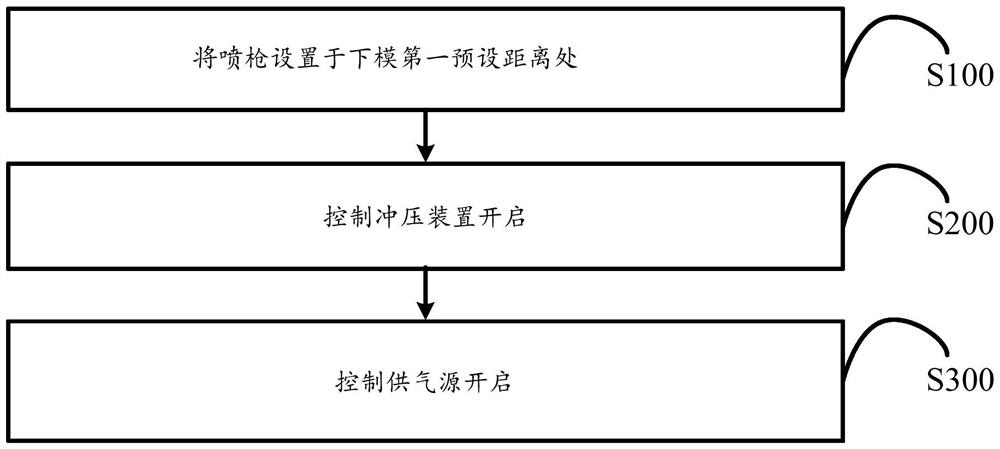

[0048] The present invention also provides a spraying method, please refer to image 3 , as the first embodiment of the present invention, the spraying method has adopted above-mentioned spraying system, and the spraying method comprises the following steps:

[0049] S100, setting the spray gun at the first preset distance of the lower mold;

[0050] S200, controlling the stamping device to open;

[0051] S300, controlling the air supply source to be turned on.

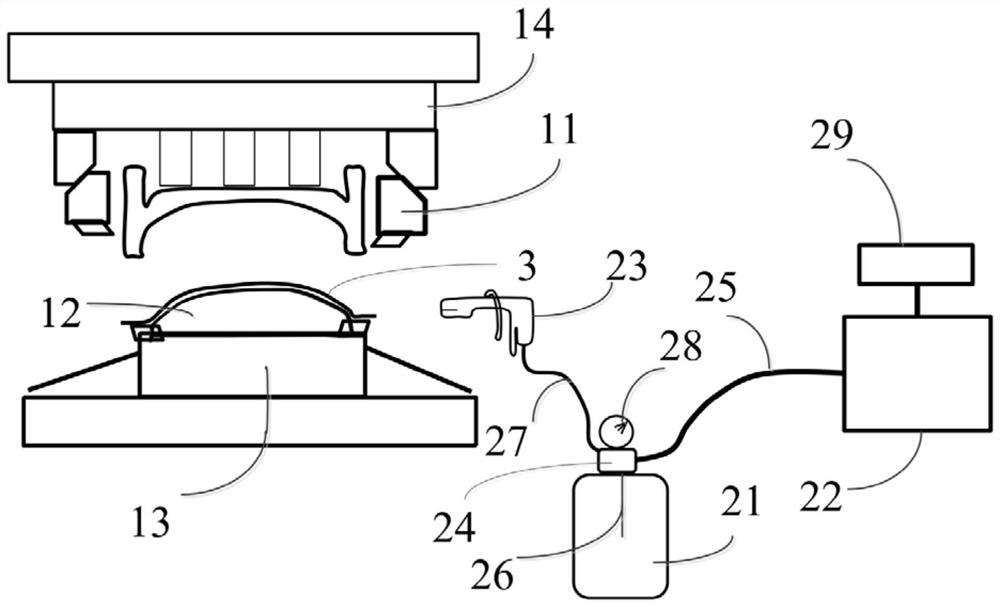

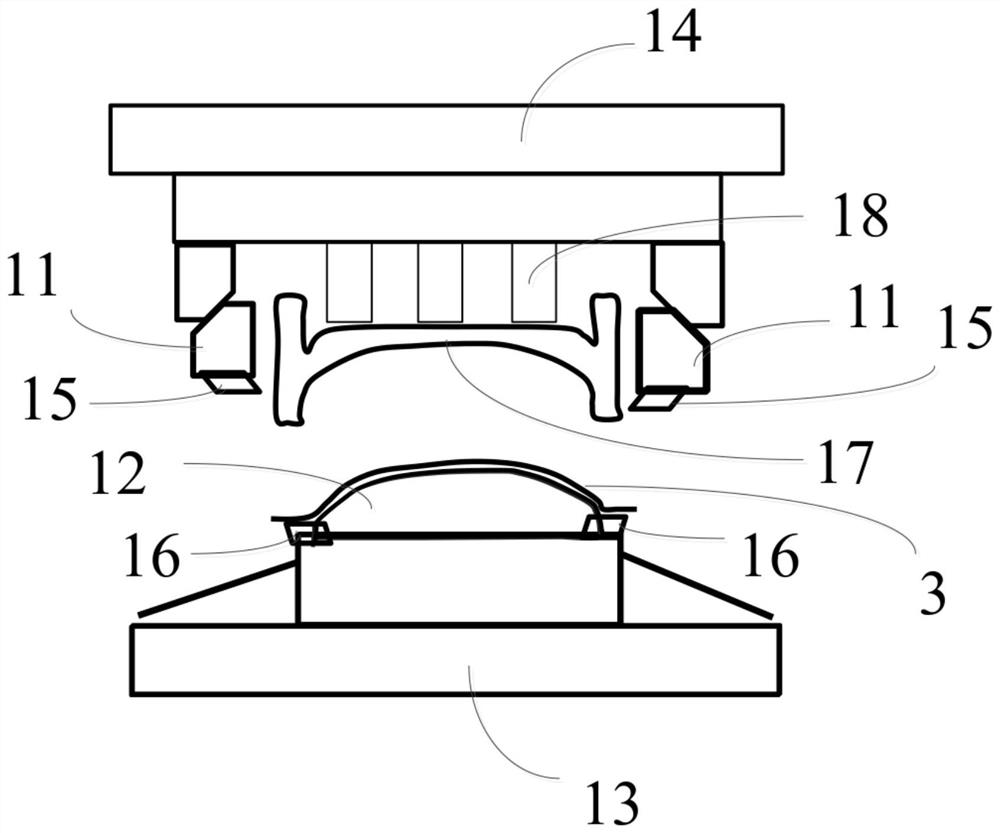

[0052] In the above embodiment, the spraying system includes an oil spraying device and a stamping device; the stamping device includes an upper die and a lower die arranged below the upper die, and the lower die is used to place the workpiece to be flanged; the oil spraying device includes an oil storage tank, an air supply source , spray gun, pressure reducing valve, the air supply source is connected to the pressure reducing valve through the air pipe, the oil storage tank is connected to the pressure reducing va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com