Oil spraying device of fireproofing material pressing machine mold

A technology of fuel injection device and refractory material, which is applied in the field of press equipment and can solve the problems that the fuel injection device cannot be moved, the fuel injection effect is not ideal, and the oil is difficult to use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings. It is only stated here that the words for directions such as up, down, left, right, front, back, inside, and outside that appear or will appear in the text of the present invention are only based on the accompanying drawings of the present invention, and are not specific to the present invention. limited.

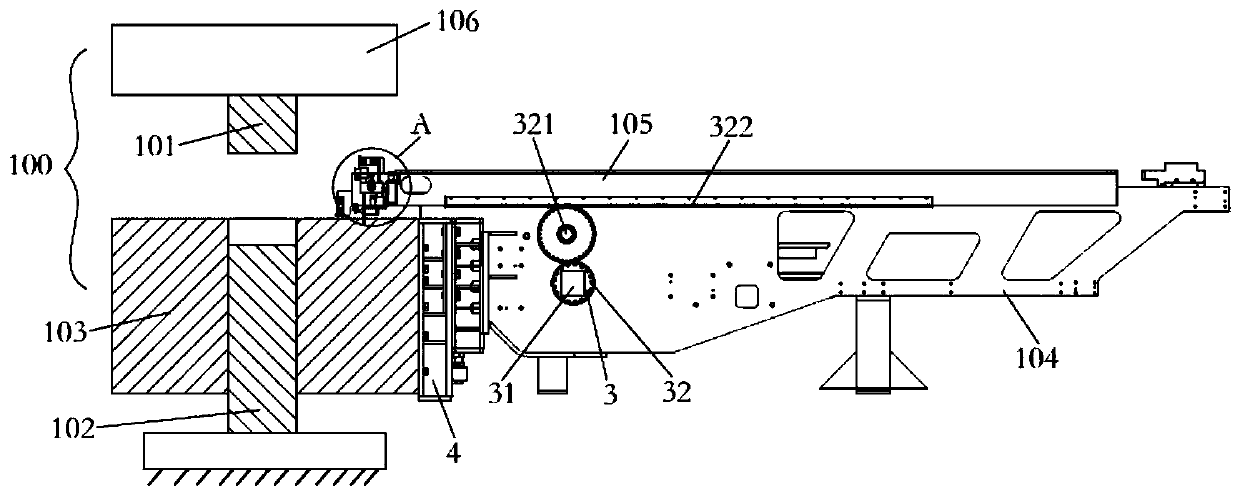

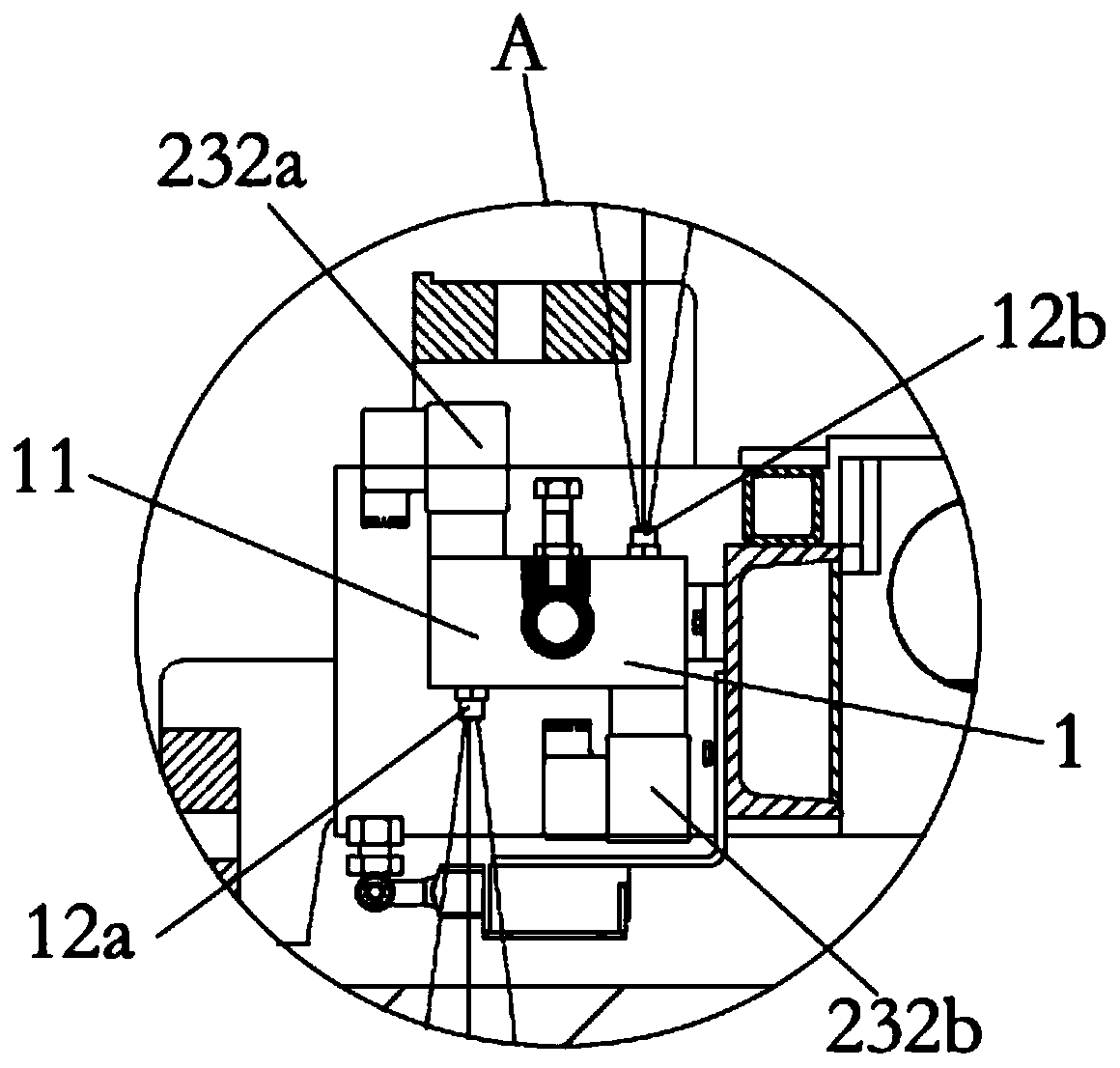

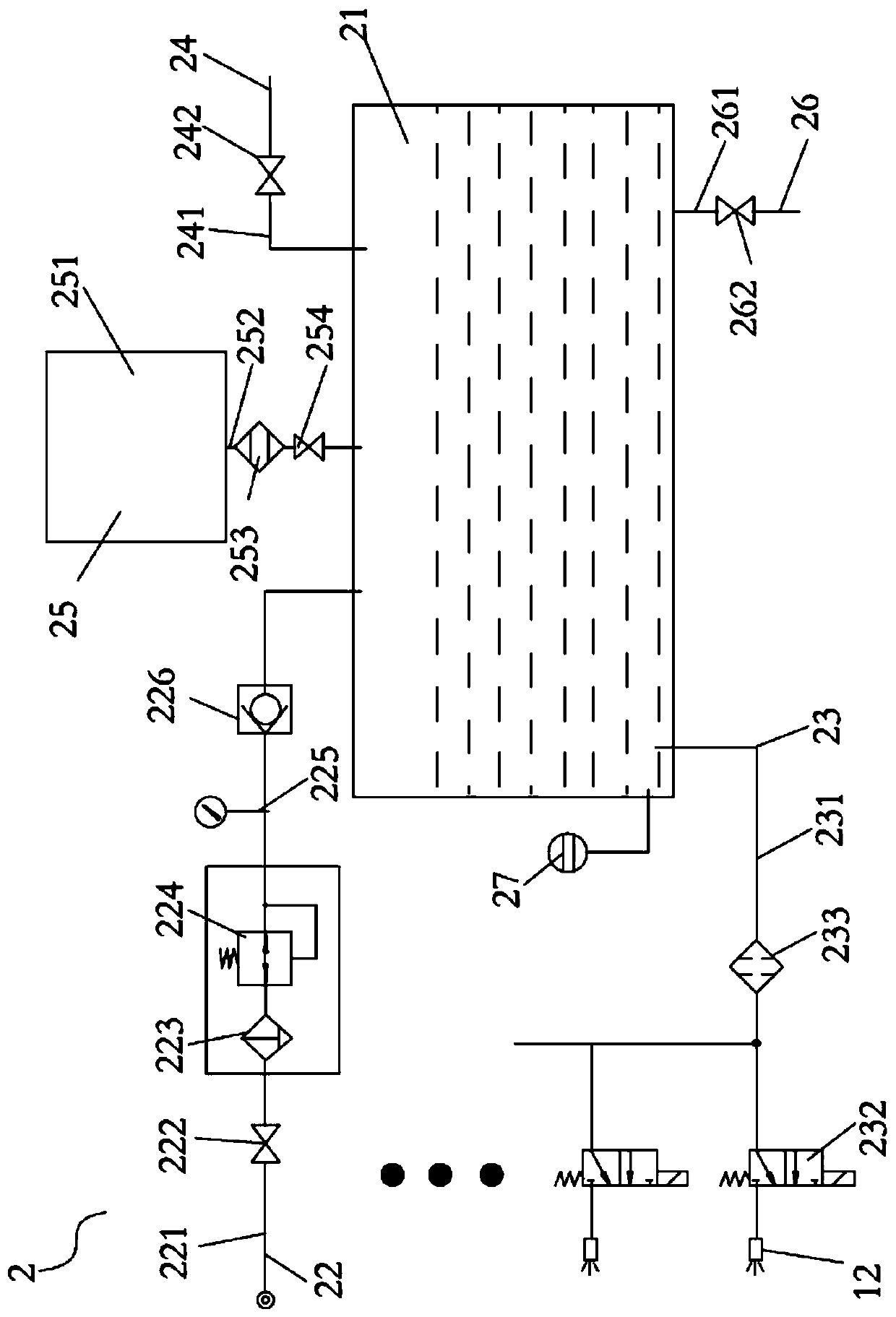

[0033] In order to solve the problem that the viscous raw material in the refractory material is bonded to the upper mold core 101 and the lower mold core 102 of the press 100 during the pressing of the adobe by the press 100, the upper mold core 101 and the lower mold core 102 of the press 100 need to be fixed. The core 102 is oiled or sprayed with oil to prevent sticky blanks from sticking to the press 100 . It should be noted that with the continuous breakthr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com