Heat-processing temperature-cntrolled heat-insulation material, its preparing method and use

A technology of thermal insulation materials and thermal processing, which is applied in the field of thermal insulation materials and its preparation, can solve problems such as weak bonding, insufficient thermal insulation performance of basalt fiber cloth, easy cracking and falling off, etc., so as to improve simplicity and flexibility, and solve all problems. The problem of process insulation and the effect of strengthening the insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] Example 1 The reduction of the cooling rate of the surface of the hot forging by the high-viscosity thermal insulation material of the present invention

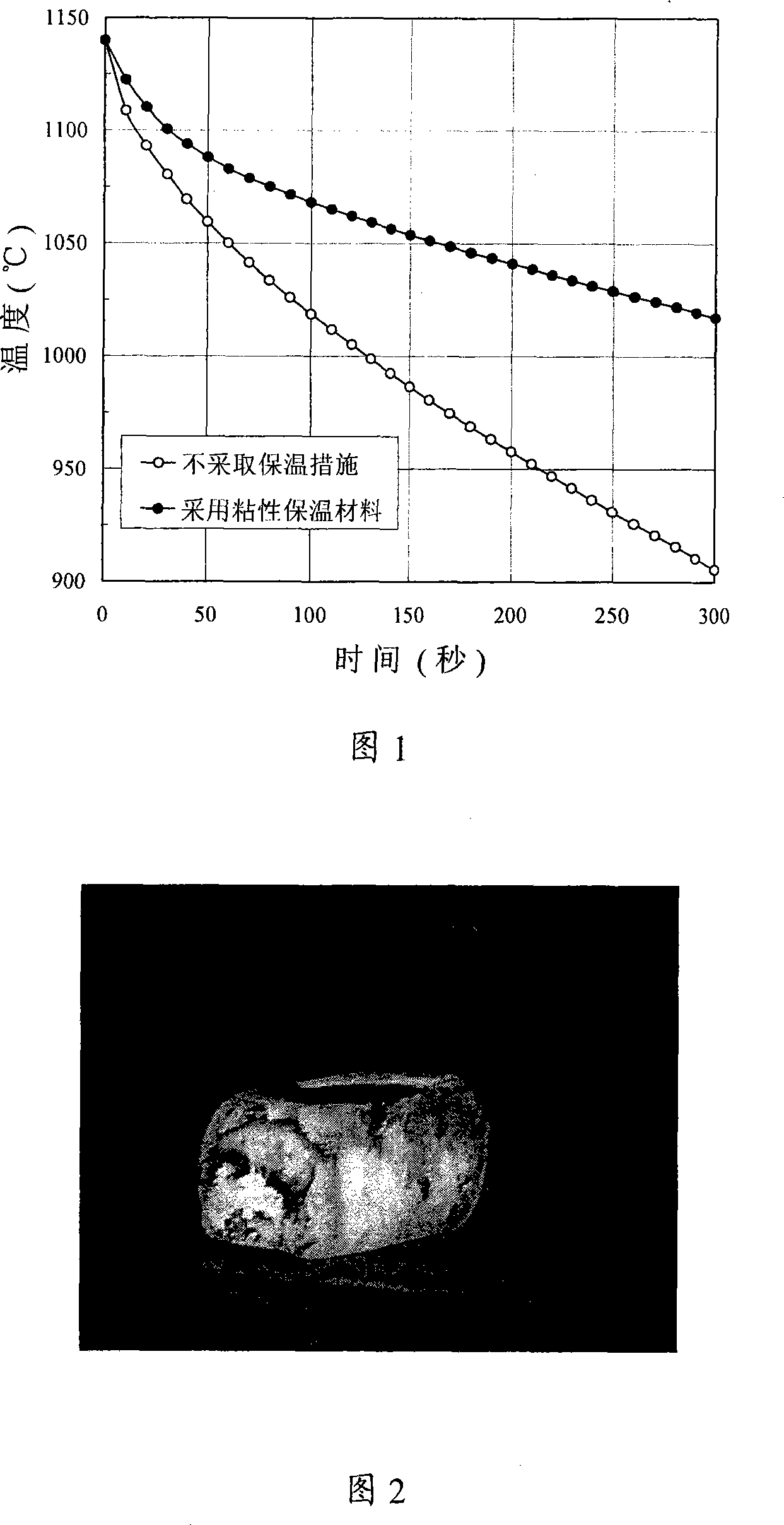

[0066] A comparison experiment of hot forging was carried out on a 5 ton electro-hydraulic hammer using a GH4742 superalloy billet weighing 20 kg. Two billets with the same size and weight, one of which is made of high-viscosity heat-insulating material, and the other is not taken with heat-insulation measures. The forging experiment is carried out on a forging hammer. The initial heating temperature is 1140°C. During the forging process, the surface temperature of the billet changes with time. Condition. Figure 1 shows the effect of high-viscosity thermal insulation material on the cooling rate of the surface of hot forgings. It can be seen from Figure 1 that the temperature drop rate of the billet is significantly slowed down after the use of viscous thermal insulation material. If the final forging temperature of...

Embodiment 2

[0068] Example 2 The improvement of the cooling speed of the hot forging surface by the multi-layer composite thermal insulation material

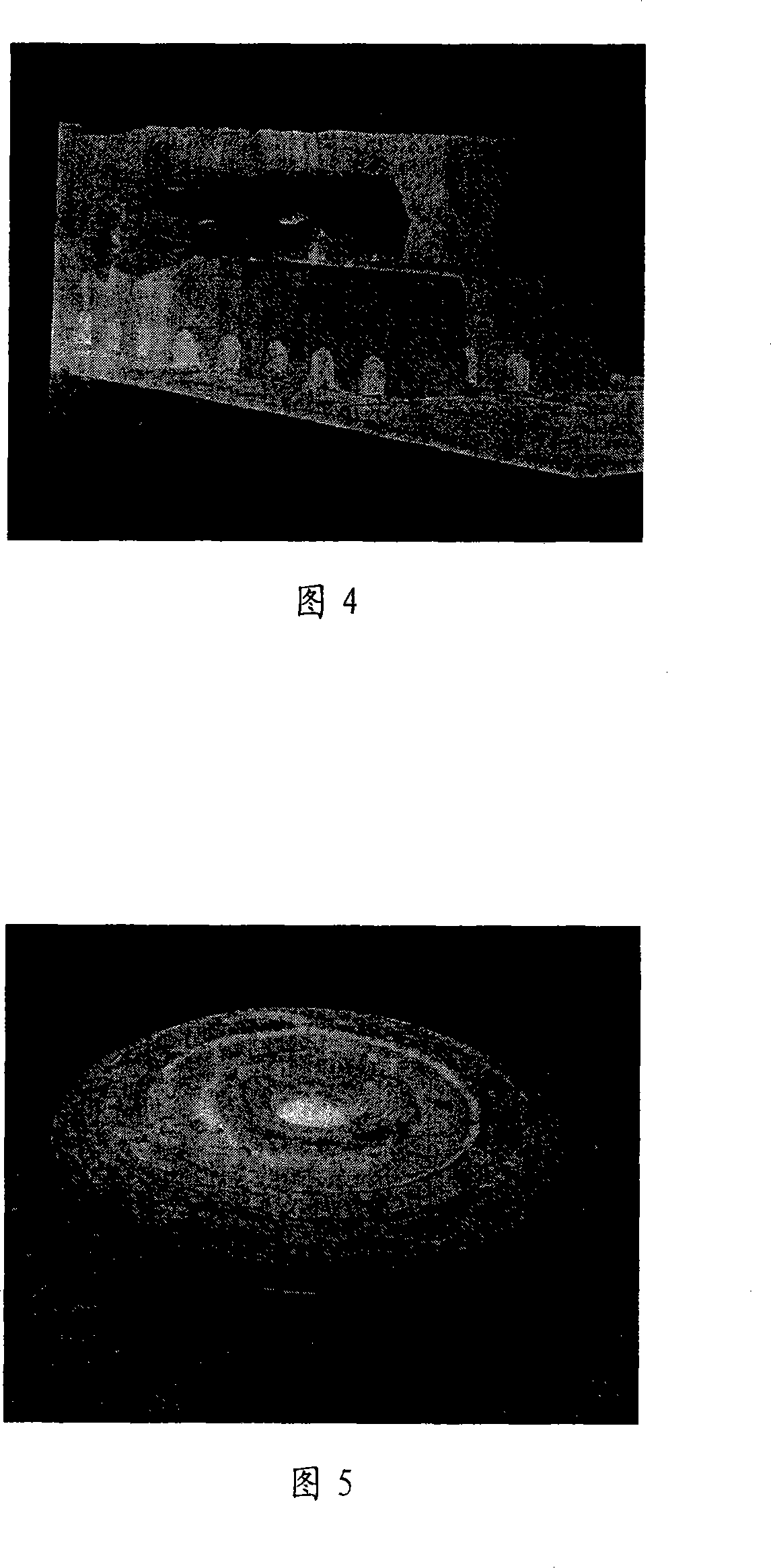

[0069] The multi-layer composite thermal insulation material has good heat insulation performance, and can reduce the contact heat transfer heat flux between the blank and the mold from 200kW·m under direct contact conditions. -2 Reduced to 40kW·m when using insulation materials -2 the following. Hot die forging is performed on a hydraulic press, and its characteristic strain rate is usually on the order of 0.01s -1 to 0.1s -1, the total time for die forging of disc-shaped forgings is generally less than 100s. If the mold preheating temperature is 600°C, within the above forging time range, the surface temperature of the billet will drop by about 10% of the original temperature of the billet. For example, as shown in Figure 3 For the multi-layer insulation material shown, when the initial temperature of the billet is 1150°C, the surfa...

Embodiment 3

[0071] Example 3 The use effect of the thermal insulation material of the present invention under different thermal processing conditions

[0072] In this embodiment, a large-size GH4698 alloy turbine disk forging with a diameter of 1200 mm for a gas turbine is die-forged on a 1MJ counter-hammer, and the total load required for forging the forging has reached the limit of the equipment capacity. Under the condition that no heat preservation measures are used on the forging hammer, the surface temperature of the blank should be kept higher than 950°C, the allowed forging time should not exceed 150s, and the number of hammering hammers should not exceed 40 hammers. Numerical simulation calculations and experiments have shown that under the above conditions Under this condition, the forging cannot be completed, the forging cannot fill the cavity, and the diameter cannot reach the specified size. Die forgings of predetermined size can only be obtained by greatly extending the fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com