An optical element for a light emitting device and a method of manufacturing thereof

A technology of optical components and light-emitting devices, applied in chemical instruments and methods, luminescent materials, electrical components, etc., can solve problems such as changes, deviations, and functional degradation of optical components, and achieve high durability, high preparation performance, and improved grinding ability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

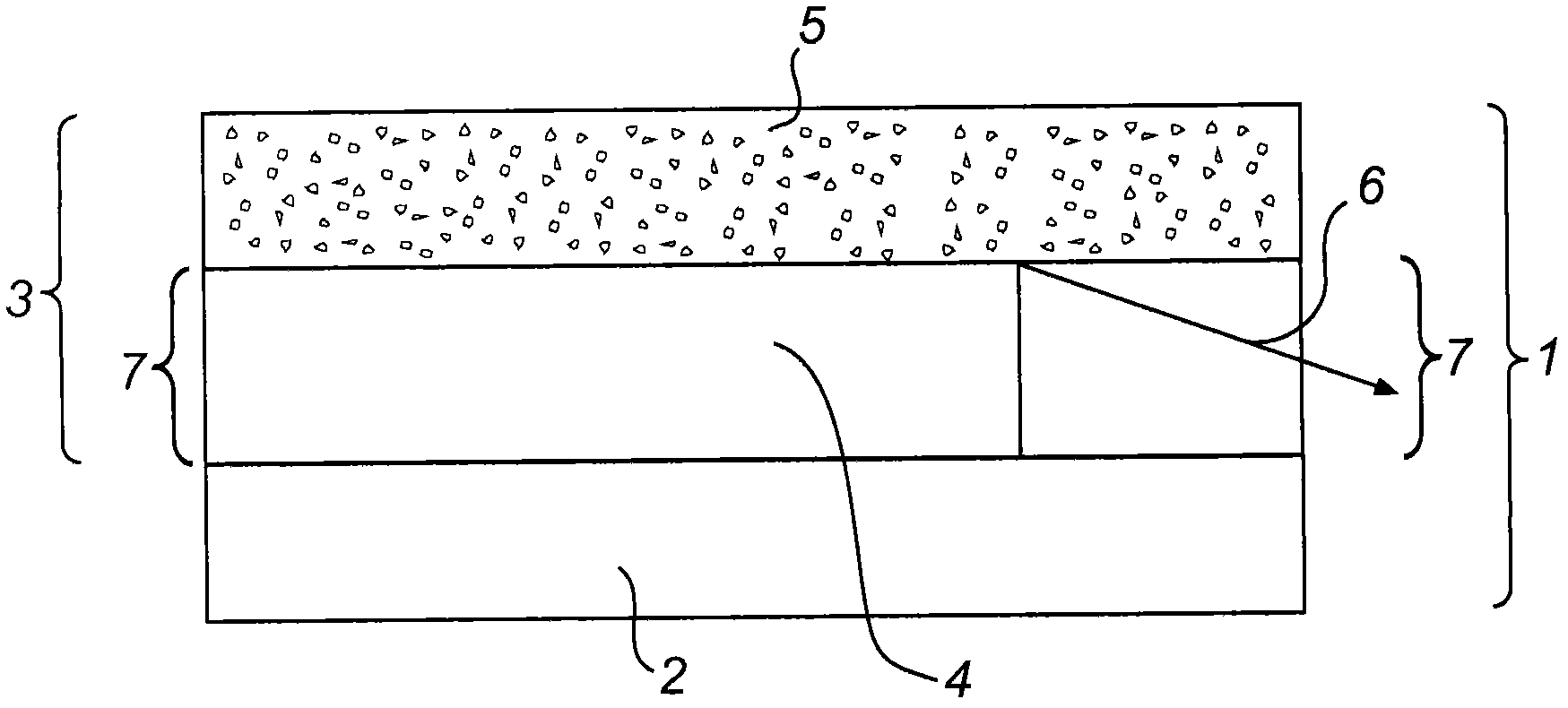

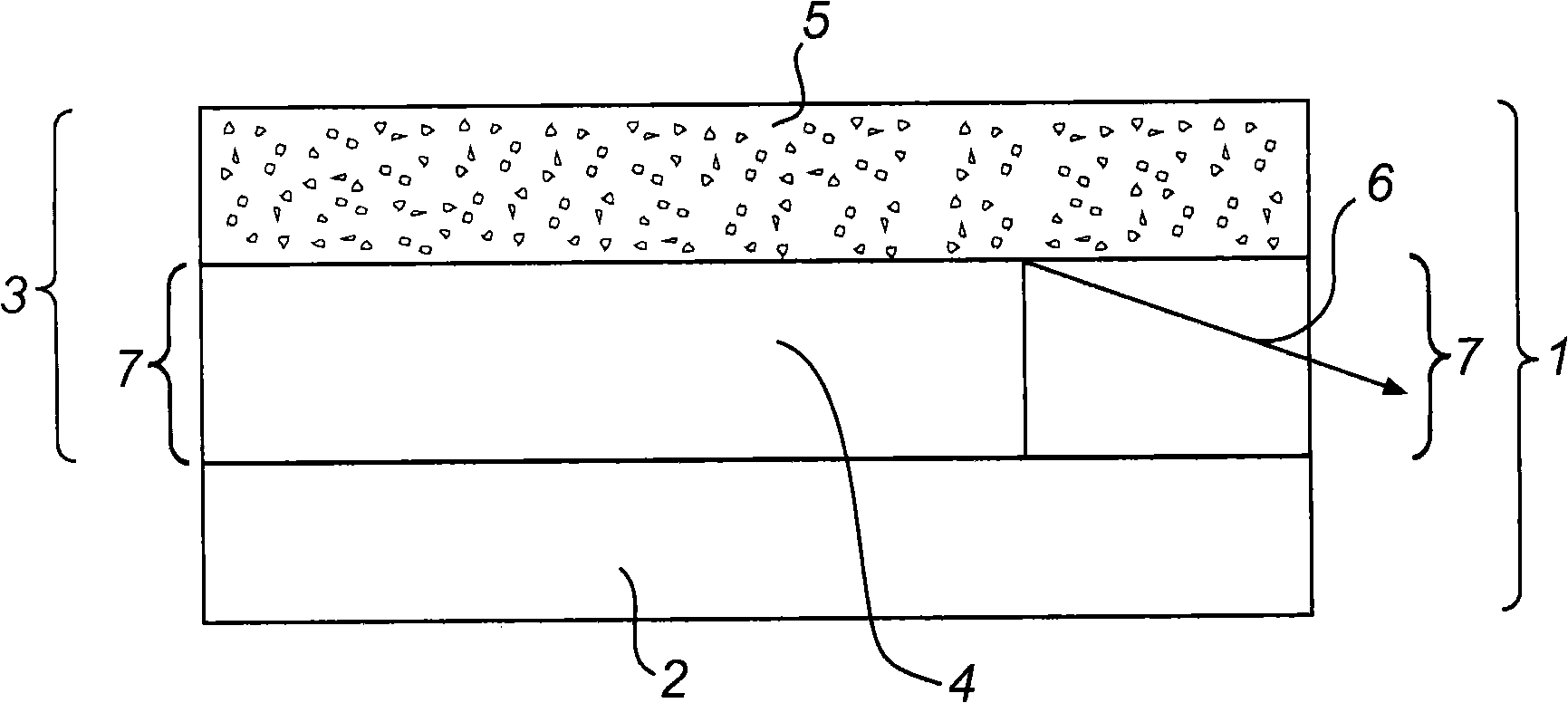

[0054] The preparation of an optical element according to the invention comprises a first layer (wavelength conversion layer), and a second layer with scattering properties, wherein the optical element is based on Y 3 Al 5 o 12 .

[0055] The following oxide compositions were used for the green body:

[0056] Y 2 o 3 , specific surface area 15m 2 / g, available from Rodia;

[0057] Al 2 o 3 , specific surface area 8m 2 / g, available from Reynolds / Malakoff;

[0058] CeO 2 , specific surface area 4m 2 / g, available from Rodia; and

[0059] Gd 2 o 3 (in the case of a red-shifted wavelength conversion layer), the specific surface area is 17m 2 / g.

[0060] Alternatively, will be used for sintering based on Y 3 Al 5 o 12 An appropriate flux for ceramic materials SiO 2 Added to the first layer at a concentration of 200-2000 ppm and added to the second layer at a concentration of 0-500 ppm. The first layer is doped with 0.01-2% Ce.

[0061] The green body is pres...

PUM

| Property | Measurement | Unit |

|---|---|---|

| reflectivity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com